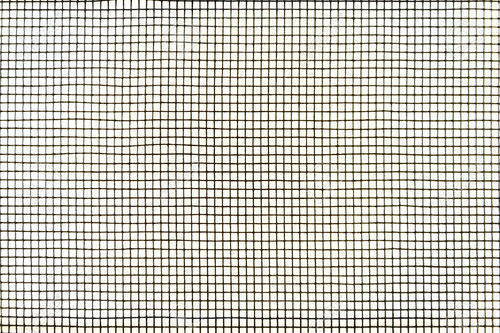

Wire Mesh Circular Screen

Price 50 INR/ Unit

Wire Mesh Circular Screen Specification

- Hole Shape

- Circular

- Surface Treatment

- Galvanized / Polished

- Aperture

- 0.2 mm 10 mm

- Length

- Up to 2000 mm

- Wire Gauge

- 10-24 Gauge

- Product Type

- Wire Mesh Circular Screen

- Mesh Type

- Plain Weave / Twill Weave

- Mesh Style

- Woven / Perforated

- Material

- Stainless Steel / Mild Steel

- Alloy

- SS304 / SS316 / MS

- Application

- Filtration, Sieving, Separation

- Dimensions

- Customer Specific (e.g., Diameter 100 mm 2000 mm)

- Wire Diameter

- 0.5 mm 2 mm

- Weight

- Customized as per size and mesh

- Color

- Silver

- Corrosion Resistance

- High (for SS screens)

- Usage

- Chemical, Mining, Food Processing, Pharmaceutical, Agro Industries

- MOQ

- As per order

- Edge Finishing

- Flat Ring / Welded / Untrimmed

- Temperature Resistance

- Up to 700°C (for SS screens)

- Packing Type

- Wooden Box / Carton

About Wire Mesh Circular Screen

We specialize in manufacturing Circular Screen Filters in various high quality materials including CRC, Mild Steel, G.I., SS-304, SS-316, or other materials as per clients requirements. The Circular Screen Filters are manufactured using high-grade materials in accordance with industry standards. Indo German Wire Screen Co. has the in-house fabrication capabilities to provide a custom product for unique or specialty applications, if required.

The aluminium ring provides the required sturdiness to the Stainless-Steel circle so that it can be used as filters for oil, suction line strainers, extruder screens, etc. The cloths are made from multifilament fibres, monofilament fibres, or spun fibres with different weave patterns such as twill weave, plain weave etc. The clothes will be finished in numerous ways like Heat set, calendared, single-glazed to facilitate easy cake release.

Superior Durability and Resistance

Our screens are crafted from premium stainless steel and mild steel alloys, delivering remarkable corrosion resistance and operating stability at temperatures reaching 700C. This makes them ideal for demanding environments in chemical, mining, and processing industries.

Customizable for Every Application

Choose from a wide range of mesh types, wire gauges, and dimensions to precisely suit your filtration, sieving, or separation needs. Mesh aperture, surface finish, edge style, and packing are all customizable for maximum compatibility with your operational requirements.

Safe and Secure Packaging

To ensure safe delivery, screens are packed in sturdy wooden boxes or cartons. This protects the mesh from potential damage during transit and allows for convenient handling and storage, whether youre ordering in bulk or smaller quantities.

FAQs of Wire Mesh Circular Screen:

Q: How is the Wire Mesh Circular Screen manufactured for optimal performance?

A: The screens are engineered using precision weaving or perforating processes, with edge finishing options such as flat ring, welded, or untrimmed to enhance structural integrity and fit your application. Made from stainless steel or mild steel, the mesh is calibrated for accurate aperture and wire diameter specifications.Q: What industries commonly use Wire Mesh Circular Screens?

A: These screens are widely used in chemical, mining, food processing, pharmaceutical, and agro industries. Their robust construction and customizable features make them suitable for filtration, sieving, and separation tasks across diverse sectors.Q: When should I choose stainless steel for my mesh screens?

A: Select stainless steel when your application demands high corrosion resistance and the ability to withstand elevated temperatures up to 700C. SS304 and SS316 alloys provide reliable operation in aggressive environments compared to mild steel.Q: Where can customized dimensions be applied to these screens?

A: You can specify any diameter between 100 mm and 2000 mm, as well as other dimensional requirements, when placing your order. This flexibility allows the screens to be tailored for specific equipment and processes in your facility.Q: What is the benefit of surface treatments like galvanizing or polishing?

A: Galvanized or polished surface treatments enhance the screens resistance to corrosion and make cleaning easier. These finishes extend the lifespan of the mesh and improve safety by reducing contamination risks in sensitive applications.Q: How is the product packaged and shipped to ensure quality?

A: Wire mesh screens are packed in wooden boxes or cartons, depending on order size and requirements. This secure packaging minimizes the risk of damage during shipping and storage, ensuring you receive the product in excellent condition.Q: Can the mesh style and type be customized for specific filtration needs?

A: Yes, you can select from woven, perforated, plain weave, or twill weave styles. This allows the mesh to be tailored for precise filtering, sieving, and separation tasks, offering optimal performance based on your application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Screen Category

Wire Mesh Filter Screen

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Fine Mesh

Color : Silver

Material : Stainless Steel

Product Type : Other, Wire Mesh Filter Screen

Hole Shape : Other , Square

Stainless Steel Screen

Minimum Order Quantity : 50 Feet, ,

Mesh Type : Steel Wire Mesh

Color : Silver

Material : Stainless Steel

Product Type : Wire Mesh

Wire Screen

Mesh Type : Other , Wire Mesh

Color : Silver / Black / Green

Material : Other, Mild Steel / Stainless Steel / GI

Product Type : Other, Wire Screen

Hole Shape : Other , Square

Stone Screen

Mesh Type : Steel Wire Mesh

Color : Silver

Material : Other, Metal

Product Type : Wire Mesh

Hole Shape : Square Hole

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry