Flex Sifters Sieves

Price 50 INR/ Square Foot

Flex Sifters Sieves Specification

- Product Type

- Flex Sifters Sieves

- Material

- Stainless Steel

- Metal Type

- Steel

- Color

- Sliver

Flex Sifters Sieves Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

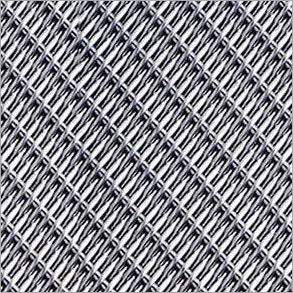

About Flex Sifters Sieves

Flex Sifters Sieves offered by us are specifically designed with the ability to withstand high-stress forces and impact caused by high centrifugal action. They are used for sizing & separation of various anhydrous materials with complete reliability. These sieves are fabricated using a strong metal alloy with corrosion resistant surface finish. They are easy to install & maintain and show a long service life. Flex Sifters Sieves maintain proper particle size distribution even after continuous use for long hours. They are also admired for showing good thermal stability and high deformation resistance. These sifter sieves are available in customized configurations at cost effective prices for our esteemed clients.

Special Features ofFlex Sifters Sieves:

- Provided sieves have been designed as per international standards.

- Featured with herring bone or round or hexagonal or square mesh shape

- Made of 316L grade stainless steel

- Woven surface pattern, ability to endure high stress and standard thickness level

Product details

|

Hole Shape |

Round, Square, Grater, Oblong Slotted, Herring Bone, Hexagonal |

|

Type |

Woven |

|

Standards |

ASTM E-674, ASTM-E-454 |

|

Material |

Stainless Steel-316 and 316-L |

|

Hole Sizes |

150 microns to 25 mm |

Premium Stainless Steel Construction

These Flex Sifters Sieves are constructed entirely from high-grade stainless steel, ensuring longevity, corrosion resistance, and consistent performance in demanding environments. The polished finish not only adds visual appeal but also simplifies maintenance, making these sieves suitable for continuous industrial use.

Adaptable Plate Mesh Design

With their unique plate mesh architecture, our sieves offer precise separation and filtration for a wide range of materials. This flexible mesh style allows for effective processing of powders, grains, or granules, making them adaptable to numerous industries from food to pharmaceuticals.

FAQs of Flex Sifters Sieves:

Q: How are Flex Sifters Sieves typically used in industrial applications?

A: Flex Sifters Sieves are commonly utilized for separating, grading, and filtering materials such as powders, granules, and small solids in industries like food processing, pharmaceuticals, and chemicals. Their plate mesh design ensures efficient and precise filtration, supporting various processing requirements.Q: What materials are these sieves made from, and why is that beneficial?

A: These sieves are manufactured from high-quality stainless steel, which provides excellent corrosion resistance, durability, and a polished surface for easy cleaning. This material selection ensures the sieves maintain their integrity and performance even in harsh or demanding environments.Q: When should you consider choosing plate mesh style sieves over other mesh types?

A: Plate mesh style sieves are particularly advantageous when you require consistent particle size separation and enhanced product purity. Opt for this style when your process demands durability, easy cleaning, and reliable filtration for a variety of materials.Q: Where are your Flex Sifters Sieves manufactured and exported from?

A: Our Flex Sifters Sieves are proudly manufactured, supplied, and exported from India. We serve clients worldwide as a reputable exporter, manufacturer, supplier, and trader, ensuring efficient global distribution and high product standards.Q: What is the process for ordering these sieves from your company?

A: To order Flex Sifters Sieves, simply contact us with your specifications, such as size, mesh style, and quantity. Our team will guide you through customization, provide a quotation, and manage swift shipping to ensure you receive products tailored to your requirements.Q: How does the polished surface treatment enhance product performance?

A: The polished surface treatment minimizes material adhesion and buildup, allowing for easier cleaning and maintenance. This finish also reduces contamination risks, making the sieves suitable for sensitive processes involving food or pharmaceuticals.Q: What are the key benefits of using your stainless steel Flex Sifters Sieves?

A: Key advantages include superior corrosion resistance, long service life, hygienic design, and adaptability to different industrial processes due to the robust stainless steel and plate mesh construction. These benefits help enhance productivity and reliability in your operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

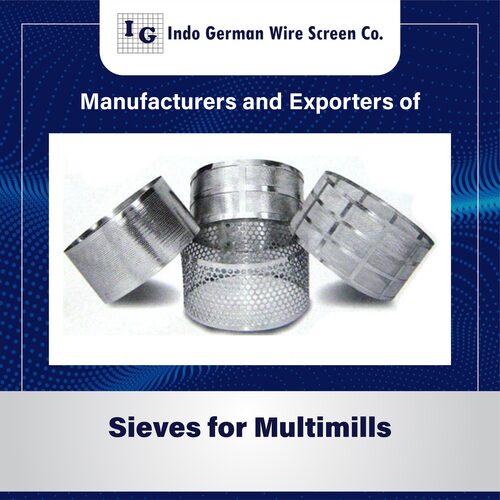

Multimill Sieves For Pharma

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet

Product Type : Multimill Sieves

Color : Silver

Material : Others, Stainless Steel

Multi Mill Sieves

Price Range 1200.00 - 5000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Product Type : Multi Mill Sieves

Color : Black

Material : Aluminum

Test Sieves

Price Range 1750.00 - 5500.00 INR / Piece

Minimum Order Quantity : 2 Pieces

Product Type : Test Sieves

Color : Silver

Material : Copper

Stainless Steel Dutch Sieves

Price Range 100.00 - 300.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Stainless Steel Dutch Sieves

Color : Silver

Material : Stainless Steel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry