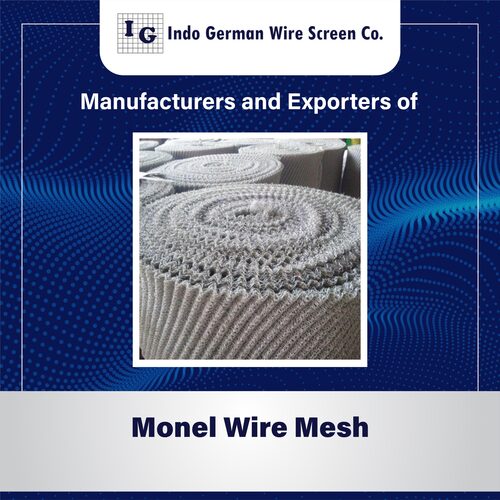

Monel Wire Mesh

Monel Wire Mesh Specification

- Length

- 30 Meter / Roll

- Wire Gauge

- 2 mm to 12 mm

- Hole Shape

- Square

- Aperture

- 0.5 mm to 10 mm

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Other

- Alloy

- Monel 400 / Monel K500

- Application

- Filtration, Chemical Processing, Marine, Oil & Gas

- Dimensions

- Customized as per requirement

- Wire Diameter

- 0.5 mm to 2 mm

- Weight

- Dependent on size and mesh count

- Color

- Silver

Monel Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Monel Wire Mesh

Monel Wire Mesh is highly appreciated for having excellent structural strength with superior corrosion resistance. It is made of high-grade nickel & copper alloy and finds application for aerospace, hydrocarbon processing, chemical, and pharmaceutical industries. This mesh is also suitable to be used for valves, fittings, and heat exchangers for showing great thermal stability and ability to bear high temperatures with ease. It is available in different mesh sizes and dimensional configurations at highly competitive rates as demanded by our respected clients. Monel Wire Mesh shows good weldability, high tensile strength and superior mechanical properties at subzero temperatures.

Special Features :

- This wire mesh is suitable for filtration of saline water.

- Square shaped mesh and Dutch or twill or plain weaving technique

- High temperature proof and praiseworthy hardness level

- Ability to resist corrosion caused by stress, acid and alkali proof, unique strength

Product details

|

Material |

Monel |

|

Usage |

Industrial |

|

Technique |

Woven |

|

Stainless Mesh length |

30m |

Superior Corrosion Resistance

Monel Wire Mesh displays outstanding resistance to corrosive acids and alkalis, making it highly suitable for challenging environments, like chemical processing and marine applications. Its corrosion resistance ensures long-lasting functionality, helping to maintain safety and efficiency within industrial systems even when operating under harsh conditions.

Flexible Dimensions & Mesh Styles

This product is offered in a wide range of mesh counts, aperture sizes, wire diameters, and lengths. Both cut and selvage edge types are available, with customizable sizing upon request. The woven mesh style ensures precise filtration, and the mesh can be supplied as flat sheets or in roll form for adaptable installation across various projects.

High Strength & Thermal Stability

Constructed from Monel alloys, the wire mesh delivers high tensile strength and sustains integrity at temperatures up to 480C. It remains non-magnetic throughout use, ensuring stable performance in environments sensitive to magnetic interference, such as electronics manufacturing and specialized chemical processes.

FAQs of Monel Wire Mesh:

Q: How is Monel Wire Mesh typically used in industrial applications?

A: Monel Wire Mesh is widely employed for screening, filtration, and separation in industries like chemical processing, marine engineering, and oil & gas extraction. Its robust construction and resistance to corrosion make it ideal for filtering aggressive substances and operating in harsh environments.Q: What customization options are available for Monel Wire Mesh?

A: We offer customization for dimensions, mesh count (2 to 200 mesh), wire diameter (0.5 mm to 2 mm), length, edge type (cut or selvage), and sheet or roll format. Clients can specify their requirements to ensure the mesh fits their precise application.Q: When should I select cut edge or selvage edge types?

A: Choose a cut edge for ease of processing or further fabrication. Selvage edges are recommended for installations requiring reinforced borders, as they resist unraveling and provide additional durability, especially in repeated-use or high-tension settings.Q: Where can Monel Wire Mesh be applied beyond filtration?

A: Besides filtration and separation, Monel Wire Mesh is utilized in architectural facades, marine hardware, heat exchangers, and electromechanical shielding due to its corrosion resistance, strength, and non-magnetic nature.Q: What is the manufacturing process for Monel Wire Mesh?

A: The mesh is woven from Monel 400 or K500 alloy wires, with each wire interlaced at precise intervals to achieve the required mesh count and aperture. The surface is then polished for enhanced finish and resistance, before being supplied in your chosen format.Q: What are the main benefits of using Monel Wire Mesh?

A: Key benefits include exceptional corrosion resistance against acids and alkalis, high mechanical strength, non-magnetic characteristics, and the ability to withstand high temperatures, ensuring reliability even in challenging industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

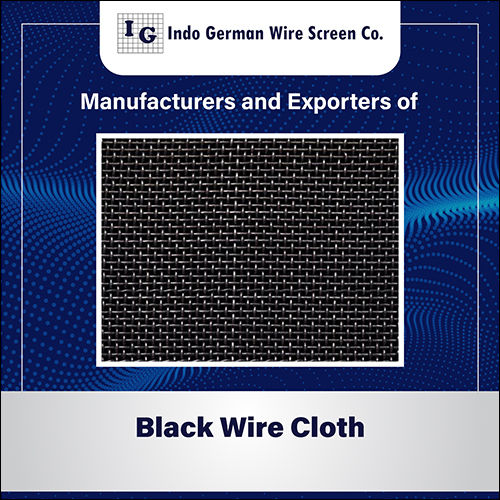

Black Wire Cloth

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Cloth

Surface Treatment : Polished

Color : Black

Mesh Type : Other

Rectangle Wire Mesh

Price 120 INR / Square Foot

Minimum Order Quantity : 10 Square Meters

Product Type : Wire Mesh

Surface Treatment : Polished

Color : Sliver

Mesh Type : Steel Wire Mesh

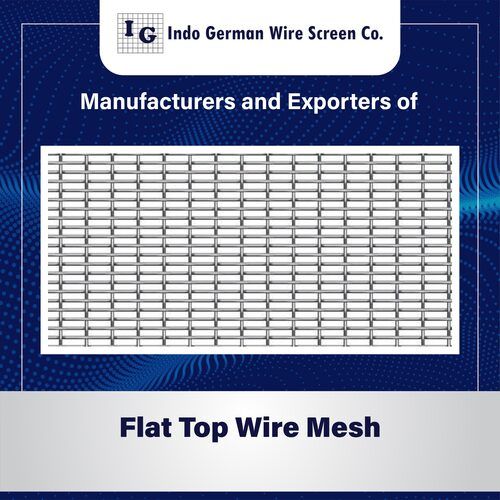

Flat Top Wire Mesh

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Product Type : Wire Mesh

Surface Treatment : Polished

Color : Sliver

Mesh Type : Steel Wire Mesh

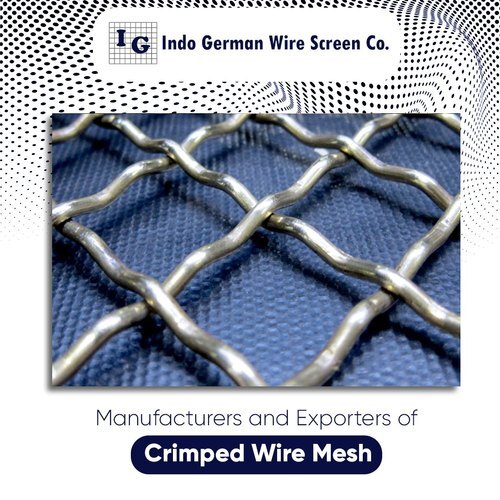

S.S. Crimped Wire Mesh

Price 150 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Surface Treatment : Painted

Color : Silver

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry