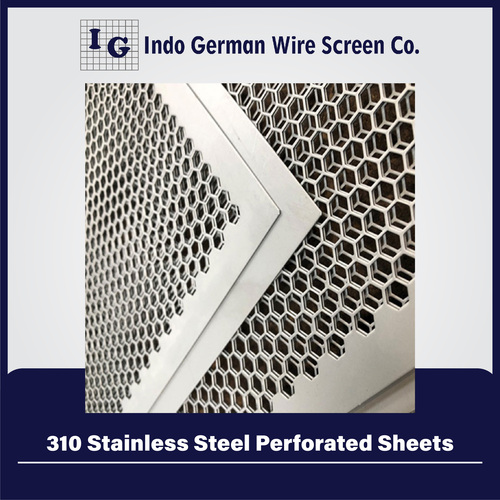

310 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

MOQ : 1 Unit

310 Stainless Steel Perforated Sheets Specification

- Surface Treatment

- Polishing

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Product Type

- 310 Stainless Steel Perforated Sheets

- Color

- Silver

310 Stainless Steel Perforated Sheets Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 310 Stainless Steel Perforated Sheets

Stainless Steel Grade 310 grade contain 25% chromium and 20% nickel, making them highly resistant to oxidation and corrosion. The high chromium and medium nickel content make these steels capable for applications in reducing sulphur atmospheres containing H2S. They are widely used in moderately carburising atmospheres, as encountered in petrochemical environments. The grade 310 is often used in cryogenic applications, due to its toughness and low magnetic permeability.Stainless Steelhas properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance.The310 Stainless Steel Perforated Sheetsare the most popular perforated sheet pattern used in the current times since they are highly versatile in use, economical in cost, and have a strong aesthetic appeal.High-Performance Industrial Solution

310 Stainless Steel Perforated Sheets are engineered for demanding industrial settings, providing robustness against high temperatures and corrosive environments. Their polished finish and precise perforations make them especially useful in filtration, sieving, and architectural projects.

Expert Manufacturing and Export Services

As an established exporter, manufacturer, supplier, and trader based in India, we ensure stringent quality checks and timely delivery for every batch of 310 Stainless Steel Perforated Sheetsserving both domestic and international clients

FAQs of 310 Stainless Steel Perforated Sheets:

Q: How is the 310 Stainless Steel Perforated Sheet manufactured?

A: These sheets are produced using advanced machinery that punches precise holes into standardized 310 stainless steel panels, followed by surface polishing to achieve a shiny silver finish and improved corrosion resistance.Q: What are the primary industrial uses of these perforated sheets?

A: 310 Stainless Steel Perforated Sheets are commonly used for filtration, separation, ventilation panels, sound suppression, and architectural design in industries such as chemical processing, power generation, and construction.Q: When should I choose 310 stainless steel over other grades?

A: You should select 310 grade stainless steel when your application demands exceptional heat resistance, oxidation protection, and durability in corrosive industrial conditions.Q: Where are these sheets typically installed?

A: These sheets are installed in industrial plants, factories, commercial buildings, and infrastructure projects across India and overseas, wherever reliable filtration or structural performance is required.Q: What is the process for ordering custom sizes or finishes?

A: You can request custom sizes or finishes by contacting our sales team with your specifications. We offer tailored manufacturing solutions to meet unique project requirements.Q: How does the surface polishing benefit the product?

A: Polishing provides a sleek, silver appearance and enhances the materials resistance to corrosion, contamination, and wear, making the sheets suitable for critical industrial operations.Q: What advantages do these sheets offer for exporters and traders in India?

A: Exporters and traders benefit from consistent quality, standardized sizing, and reliable supply chains, which help meet global market standards and fulfill large-scale industrial orders efficiently.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Perforated Sheet Category

430 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 430 Stainless Steel

Surface Treatment : Other , Polished, Matte, or as required

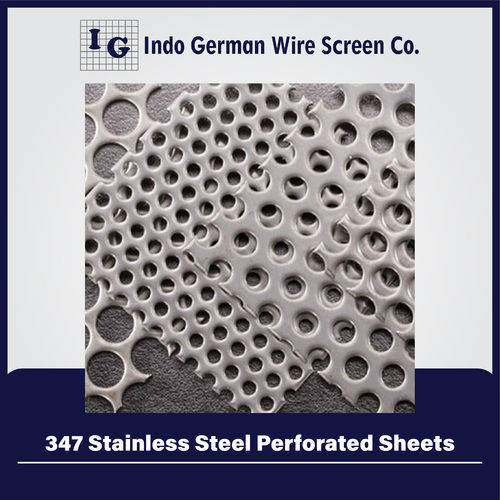

347 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 347 Stainless Steel

Surface Treatment : Other , Polished, Mill Finish

314 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Size : Standard

Usage : Industrial

304 L Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polishing

Size : Standard

Usage : Industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry