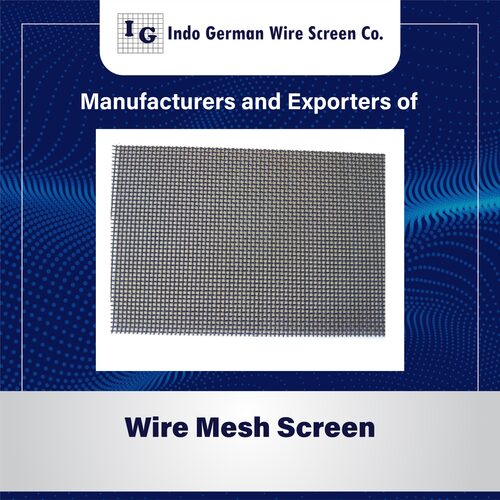

Wire Mesh Screen

Wire Mesh Screen Specification

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel, Aluminum, Steel, Copper, Iron, Polyester, Galvanized Steel, Metal Alloys

- Application

- Screen

- Color

- Silver

Wire Mesh Screen Trade Information

- Minimum Order Quantity

- 50 Feet

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Feet Per Week

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Wire Mesh Screen

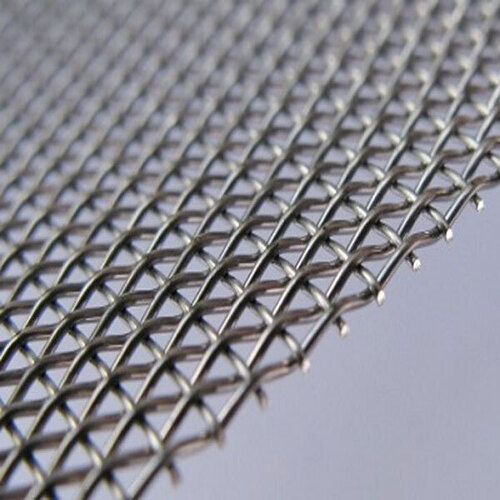

We offer our clients with a qualitative range of Wire Mesh Screen. These are heavy duty wire mesh screens and manufactured using premium grades of spring steel, mild steel, and stainless steel. Our range is specially manufactured for extremely rugged operating conditions in scalping, sizing or processing heavy abrasive materials such as ores, crushed stones, sand, gravel, metallic and non-metallic minerals, and coal slag. These are accurately woven from different mesh size and diameter as per the clients requirements.

Product details

|

Material |

Stainless Steel Wire |

|

Technique: |

Woven |

|

Type |

Weave Wire Mesh |

|

Wire Diameter |

0.80mm |

|

Usage/Application |

Industrial |

Versatile Screening Solutions

Our wire mesh screens offer versatility, suiting a broad spectrum of industrial and commercial screening needs. Available in several materials, including durable metals and polyester, these screens can be customized to fit various machinery and processes. Their welded design and square holes ensure efficient filtration and classification, backed by quality you can trust from a reputable Indian exporter.

Superior Material Choices

Choose from stainless steel, aluminum, galvanized steel, copper, iron, polyester, and custom metal alloys for your screening requirements. Each material provides unique benefits, such as rust resistance and strength, making our screens adaptable for different environments. The silver finish not only enhances aesthetics but also increases longevity in demanding applications.

FAQs of Wire Mesh Screen:

Q: How are wire mesh screens with square holes manufactured?

A: Wire mesh screens featuring square holes are produced using precision welding techniques. The chosen material, such as stainless steel, aluminum, or other listed alloys, is wire-formed and welded at the intersections, creating a sturdy mesh that maintains exact hole size and strength. The process is managed by experienced manufacturers and suppliers in India.Q: What applications are wire mesh screens most suitable for?

A: These wire mesh screens are primarily used for screening, filtering, and separating materials in industries such as mining, construction, agriculture, and chemical processing. The welded mesh style and square holes provide reliable performance for all screening needs, regardless of the material type or operational scale.Q: When should I choose stainless steel wire mesh over other materials?

A: Stainless steel is recommended when your application requires high corrosion resistance, longevity, and strength, especially in harsh environments or where hygiene is critical. Alternative materials like aluminum or galvanized steel may be more suitable for less demanding conditions or when weight is a concern.Q: Where can I source high-quality wire mesh screens from India?

A: You can source wire mesh screens directly from reputable exporters, manufacturers, suppliers, and traders located across India. Our company offers a broad selection, competitive pricing, and global export capability ensuring products meet international quality standards.Q: What is the process for customizing wire mesh screens?

A: Customization involves selecting the preferred material, mesh size, hole shape, and dimensions. After consultation, the screens are fabricated using state-of-the-art welding and finishing techniques to suit specific requirements such as mesh style, color, and application purpose.Q: How are wire mesh screens commonly used in industry?

A: Wire mesh screens are widely used for screening bulk materials, classifying particles, protecting equipment, and enhancing process safety. Their robust design and adaptable material options make them suitable for continuous operation in demanding industrial environments.Q: What are the key benefits of choosing welded mesh screens with a square hole design?

A: The square hole design provides uniform particle passage, increases screening efficiency, and reduces clogging. Welded mesh construction enhances structural integrity, ensuring durability and reliable performance over extended periods, particularly in rigorous screening applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Wire Mesh Category

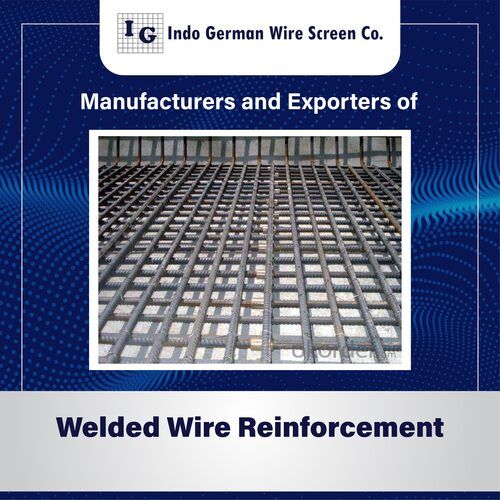

Welded Wire Reinforcement

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Product Type : Wire Mesh

Material : Other, Metal

Color : Silver

314 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Material : Stainless Steel

Color : Gray

330 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Material : Stainless Steel

Color : Gray

410 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Material : Stainless Steel

Color : Gray

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry