330 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

330 Stainless Steel Perforated Sheets Specification

- Temper

- Annealed

- Shape

- Rectangular, Square, Customizable

- Surface Treatment

- Polished, Matt Finish

- Process

- Perforating, Cutting, Punching

- Standard

- ASTM, AISI, DIN

- Material

- 330 Stainless Steel

- Type

- Perforated Sheet

- Technique

- Cold Rolled / Hot Rolled

- Thickness

- 0.5 mm to 5 mm

- Application

- Industrial, Chemical Processing, Oil & Gas, Furnace Parts, Heat Exchangers, Architectural, Food Processing

- Feature

- Corrosion Resistant, Durable, High Strength, Heat Resistant

About 330 Stainless Steel Perforated Sheets

Stainless Steel Perforated Sheets are thin sheets which are stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes to have uniform perforations throughout the entire surface. Depending on applications and requirements, patterns of perforated sheets can be round-staggered, round-straight, slotted holes. Although the process of perforating improves the exterior of metals, it has other useful special uses like protection and noise suppression.

The perforated sunshades and claddings provides privacy for the building residents without any view obstruction while controlling interior climate thus reducing the load of air conditioning and saving energy to a large extent. 330 Stainless Steel Perforated Sheets fences and banisters keep enclosed machines and other properties from damage secure and the safety of people. Indo German Wire Screen Co. has the in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

330 Stainless Steel Perforated Sheets is easy to work with and is available in different hole sizes, thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range of 330 Stainless Steel Perforated Sheets at unmatched quality and market leading prices.

Versatile Design & Specifications

These perforated sheets offer extensive customization, including thicknesses from 0.5 mm to 5 mm, various hole shapes and sizes, and finish options such as 2B, BA, No. 4, and No. 8. Open areas range from 10% to 80%, ensuring optimal airflow or filtration. Edge treatments like slit, deburred, or smooth finish enhance safety and appearance.

Superior Material Properties

Made from high-grade 330 stainless steel, these sheets deliver outstanding corrosion resistance and endure extreme temperatures up to 1149C. With a minimum yield strength of 30,000 psi and density at 7.98 g/cm, they are engineered for demanding industrial applications and high-strength requirements.

Reliable Manufacturing & Packing

Each sheet is manufactured through precise cold rolled or hot rolled techniques and is subjected to stringent ASTM, AISI, and DIN quality standards. Options for packaging include wooden pallets and PVC wrapping to ensure safe delivery. As a trusted exporter, manufacturer, supplier, and trader based in India, quality and reliability are continually assured.

FAQs of 330 Stainless Steel Perforated Sheets:

Q: How are 330 Stainless Steel Perforated Sheets manufactured?

A: These sheets are produced using cold or hot rolling methods, followed by perforating, cutting, and punching to create precise holes and edge finishes. Advanced techniques ensure consistent quality and meet international standards such as ASTM and DIN.Q: What applications are suitable for these perforated sheets?

A: They are ideal for industrial, chemical processing, oil & gas, furnace components, heat exchangers, food processing, and architectural projects due to their durability, corrosion resistance, and high temperature tolerance.Q: When should I choose a custom hole size, shape, or open area for my sheet?

A: Select custom specifications when specific airflow, filtration, or aesthetic requirements are involved. Our sheets can be tailored with hole sizes from 0.5 mm to 50 mm, shapes like round, slotted, or square, and open areas from 10% to 80% to suit your projects needs.Q: Where are the sheets packed and shipped from?

A: All sheets are securely packedeither on wooden pallets or PVC wrappedaccording to client requirements, and shipped from our manufacturing facilities in India, serving domestic and international markets.Q: What benefits does 330 stainless steel provide compared to other materials?

A: 330 stainless steel offers superior resistance to corrosion and oxidation, maintains structural integrity at elevated temperatures (up to 1149C), and provides high strength, making it an excellent choice for harsh environments.Q: Can I request special surface finishes and edge treatments?

A: Yes, options include 2B, BA, No. 4, No. 8 finishes, and edge treatments like slit, deburred, or smooth. Custom surface treatments, such as polished or matt finishes, are also available to meet architectural or industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

321 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 321 Stainless Steel

Surface Treatment : Other , Polished, Mill finish

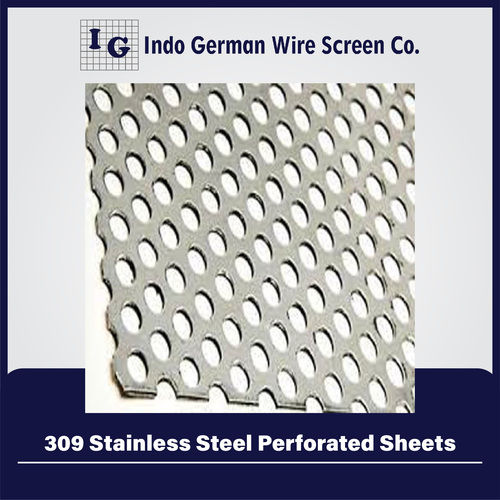

309 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 309 Stainless Steel

Surface Treatment : Other , Polished, Pickled, Annealed

304 L Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polishing

Color : Silver

Usage : Industrial

304 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Color : Silver

Usage : Industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry