321 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

321 Stainless Steel Perforated Sheets Specification

- Shape

- Sheet (rectangular and square available)

- Standard

- ASTM A240 / ASME SA240

- Surface Treatment

- Polished, Mill finish

- Process

- Punching / Perforation

- Temper

- Annealed

- Material

- 321 Stainless Steel

- Type

- Perforated Sheet

- Technique

- Cold rolled, Perforated

- Thickness

- 0.5 mm to 3 mm (customized thickness available)

- Application

- Architectural screens, Filters, Guards, Decorative panels, Industrial applications

- Feature

- Corrosion resistant, High strength, Superior finish, Excellent forming and welding characteristics

- Yield Strength

- 205 MPa min

- Packaging

- Wooden cases, customized packing options

- Open Area

- Variable, per request

- Width

- 500 mm to 1250 mm

- Protection

- PVC coated optional

- Density

- 7.9 g/cm³

- Melting Point

- 1400°C

- Tensile Strength

- 515 MPa min

- Pitch

- As per specification or customized

- Length

- 1000 mm to 2500 mm

- Hole Shape

- Round, Square, Slotted, Customized

- Edge Configuration

- Plain/trimmed edges

- Elongation

- 40% min

About 321 Stainless Steel Perforated Sheets

Stainless Steel 321 grade has titanium-stabilized austenitic stainless steel with good corrosion resistance and excellent resistance to chromium carbide precipitation when exposed to high temperatures. Stainless Steel 321 Grade are normally used in chemical processing and oil and gas refineries. Stainless Steel has features like attractive appearance and high cleanability, low-maintenance, durable material and environmentally friendly (recyclable). Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it to become one of the most extensively used construction materials across a varied set of industries.The perforated sunshades and cladding provides privacy for the building residents without any obstruction of view while controlling interior climate, thus reducing the load of air conditioning and saving energy to a large extent. 321 Stainless Steel Perforated Sheets fences and banisters keep enclosed machines and other properties secure from damage and the safety of people. Indo German Wire Screen Co. has in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

Customized Design and Superior Quality

Choose from various shapes, sizes, and finishes for 321 stainless steel perforated sheets. Whether you need polished, mill finish, or unique hole patterns, customization is available to suit architectural screens, filters, or industrial guards. Superior corrosion resistance and forming properties ensure longevity and versatility.

Safe and Reliable Packaging Options

Sheets are packed with advanced protection methods, including optional PVC coating and sturdy wooden cases. Custom packaging solutions are offered to maintain the integrity of your order during transit, safeguarding your investment regardless of destination.

Certified Performance and High Strength

Compliant with ASTM A240/ASME SA240 standards, these sheets offer excellent mechanical strength, with a yield strength minimum of 205 MPa and tensile strength of 515 MPa. Their exceptional elongation and resistance to corrosion make them ideal for demanding environments.

FAQs of 321 Stainless Steel Perforated Sheets:

Q: How can I specify the hole shape and pitch for my 321 stainless steel perforated sheet order?

A: Customers can choose from a range of hole shapes such as round, square, slotted, or request custom configurations. Pitch and open area can be tailored as per your specification to meet the requirement of your application. Simply communicate your preferences when placing your order.Q: What are the main benefits of using 321 stainless steel perforated sheets in architecture and industry?

A: These sheets offer high corrosion resistance, robust strength, and an attractive finish. They are highly formable and weldable, making them ideal for architectural screens, decorative panels, industrial filters, and protective guards.Q: When should I consider adding PVC coating to my perforated sheets?

A: PVC coating is recommended when additional surface protection is required, especially during handling, installation, or in environments with likelihood of abrasion or exposure to moisture. This helps further extend the sheets durability and preserves its aesthetic.Q: Where are these sheets commonly exported and supplied from?

A: 321 stainless steel perforated sheets are manufactured and exported primarily from India. They are supplied globally and suitable for diverse construction, industrial, and decorative applications worldwide.Q: What is the manufacturing process for 321 stainless steel perforated sheets?

A: The sheets are produced using a cold-rolled technique, followed by precision punching or perforation according to the desired hole pattern. Additional surface treatments like polishing or mill finish may be applied based on customer requirements.Q: How do the sheets mechanical properties benefit my application?

A: With a yield strength of at least 205 MPa, tensile strength of 515 MPa minimum, and excellent elongation (40% min), these sheets resist deformation, accommodate forming, and deliver long-lasting structural integrity even in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

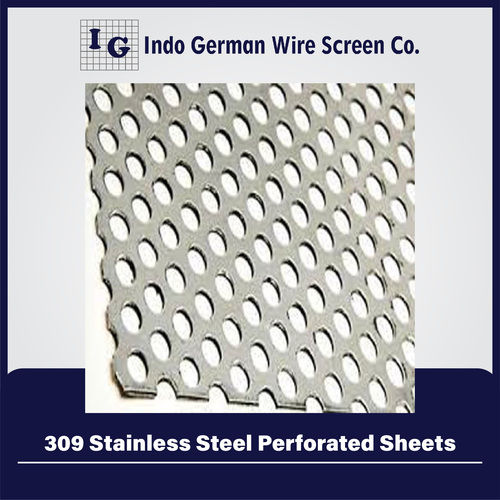

309 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 309 Stainless Steel

Surface Treatment : Other , Polished, Pickled, Annealed

Process : Perforating, Cutting, Forming

Temper : Soft, Hard, Half Hard

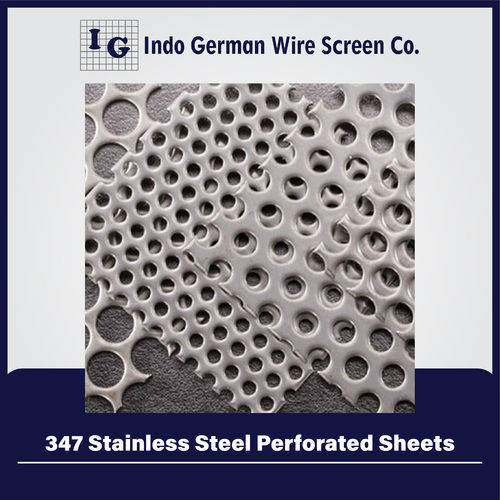

347 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 347 Stainless Steel

Surface Treatment : Other , Polished, Mill Finish

Process : Perforation, Punching

Temper : Soft, Hard, Half Hard

330 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 330 Stainless Steel

Surface Treatment : Other , Polished, Matt Finish

Process : Perforating, Cutting, Punching

Temper : Annealed

430 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 430 Stainless Steel

Surface Treatment : Other , Polished, Matte, or as required

Process : Perforation by mechanical stamping or punching

Temper : Annealed or as specified

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry