Hastelloy Fine Wire Mesh

Price 50 INR/ Unit

Hastelloy Fine Wire Mesh Specification

- Aperture

- 0.2 mm to 5 mm

- Length

- Rolls of 30 m and customized lengths available

- Wire Gauge

- Standard (typically available from 0.025 mm to 2 mm)

- Surface Treatment

- Coated

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Woven Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Hastelloy C-276, C-22

- Application

- Other

- Dimensions

- Customized, standard width up to 1.2 m

- Wire Diameter

- 0.025 mm to 2 mm

- Weight

- Varies by specification, typically 1.5-22 kg per roll

- Color

- Silver

- Packing

- Roll packing with moisture-proof paper or custom

- Edge Type

- Cut edge or selvage edge

- Operating Temperature

- Up to 1090°C

- Weave Type

- Plain weave or twilled weave

- Tensile Strength

- High tensile strength, up to 750 MPa

- Corrosion Resistance

- Highly resistant to acid, alkali, chloride, and oxidation

Hastelloy Fine Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Hastelloy Fine Wire Mesh

Hastelloy is a corrosion resistant alloy and has a higher work hardening rate than the austenitic stainless steels which should be taken into consideration. Hastelloy has a smooth surface and has an excellent aesthetic appearance and will not easily fray or unravel, is stable and rigid. Hastelloy construction provides durable and strong packing that can withstand the harshest environments.Fine Wire Meshis a mesh of wires combined together having fine holes on its surface.Hastelloy Fine Wire meshor wire cloth is thin woven wire meshes with mesh from 11 to 500 500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch).Hastelloy Fine Wire Meshcan be used in elevated temperature applications, due to excellent functioning in higher temperatures.Hastelloy Fine Wire meshis a versatile wire mesh having wide application in industrial, commercial and decoration.We offer an exclusive range ofHastelloy Fine Wire Meshat unmatched quality and market leading prices.

Exceptional Corrosion and Heat Resistance

Engineered from superior Hastelloy alloys, this fine wire mesh offers remarkable resistance to corrosive substances, including acids, alkalis, and chlorides. Its thermal endurance enables operation at temperatures up to 1090C, making it an excellent choice for environments where both chemical and thermal challenges must be faced.

Versatile Weave Options and Customization

Select from plain or twilled weave types to suit your filtration requirements. Apertures can be tailored from 0.2 mm to 5 mm, with wire diameters ranging from 0.025 mm to 2 mm. Custom roll lengths and widths up to 1.2 m ensure seamless integration into any system. Available surface treatments provide added protection and a silver finish.

Reliable Packing and Safe Handling

Each roll of Hastelloy wire mesh is securely packed with moisture-proof paper, or as per your specifications, to ensure the mesh arrives in optimal condition. Both cut edges and selvage edges are available for your processing and installation needs. Choose from standard weights and dimensions or request a custom configuration.

FAQs of Hastelloy Fine Wire Mesh:

Q: How is Hastelloy Fine Wire Mesh processed for specific industrial needs?

A: This mesh is manufactured using plain or twilled weaving techniques tailored to application specifics. Customization includes various mesh sizes, aperture widths (0.2 mm5 mm), and wire gauges (0.025 mm2 mm). Additional surface coatings and edge types (cut or selvage edges) can be specified to match operational demands.Q: What benefits does Hastelloy wire mesh offer over conventional stainless steel mesh?

A: Aside from robust tensile strength (up to 750 MPa), Hastelloy mesh exhibits far superior resistance to acids, alkalis, chlorides, and oxidation. It functions efficiently at higher temperatures (up to 1090C), making it suitable for harsh and corrosive environments where stainless steel might fail.Q: When should I use plain weave versus twilled weave in Hastelloy wire mesh?

A: Plain weave provides consistent, fine filtration where strength requirements are moderate. Twilled weave is ideal when higher strength and load-bearing capacity are needed, offering improved durability while maintaining effective particle separation.Q: Where is Hastelloy Fine Wire Mesh typically used?

A: Due to its high corrosion, thermal, and mechanical resilience, its widely utilized in chemical processing, oil and gas, aerospace, pharmaceuticals, and power generation industriesparticularly for filtration, sieving, and protective barriers in aggressive chemical environments.Q: What are the available packing options for delivery?

A: Hastelloy wire mesh is commonly packed in rolls protected by moisture-proof paper, with the option for custom packing solutions as per client requirements. This ensures the mesh retains its integrity during storage or transport.Q: How does the meshs customizability enhance its usage?

A: The ability to specify aperture size, wire diameter, length, width, weave type, and edge style allows the mesh to be perfectly tailored for unique applications, ensuring optimal performance and efficiency in any project.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Brass Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Application : Other

Surface Treatment : Coated

Mesh Style : Plain Mesh

Stainless Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel 304

Application : Other, Filtration, Sieving, Insect Screen, Laboratory Use

Surface Treatment : Mill Finish

Mesh Style : Other , Woven

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Highpurity Tungsten (>99.95%)

Application : Other, Filtration, catalyst support, high temperature screening, precision electronics

Surface Treatment : Other, Annealed

Mesh Style : Other , Woven

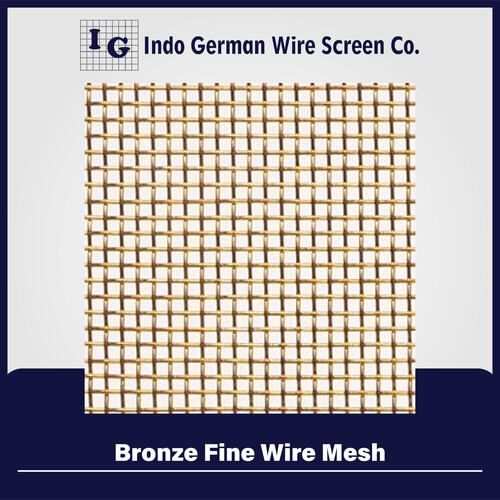

Bronze Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Phosphor Bronze

Application : Other, Filtration, Sieving, Industrial Screens, Laboratory Use, Decorative Panels

Surface Treatment : Mill Finish

Mesh Style : Other , Plain Weave

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry