Monel 400 Fine Wire Mesh

Price 50 INR/ Unit

Monel 400 Fine Wire Mesh Specification

- Surface Treatment

- Annealed

- Length

- Up to 30 meters (customizable)

- Aperture

- 0.1 mm to 10 mm

- Wire Gauge

- 10 to 28 SWG

- Hole Shape

- Square

- Product Type

- Fine Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Woven Mesh

- Material

- Monel 400

- Alloy

- Monel 400 (UNS N04400)

- Application

- Filtration, Chemical Processing, Marine, Aerospace, Oil & Gas

- Dimensions

- Width: 0.5 to 2 meters

- Wire Diameter

- 0.1 mm to 2 mm

- Weight

- Variable (dependant on mesh and size)

- Color

- Metallic Grey

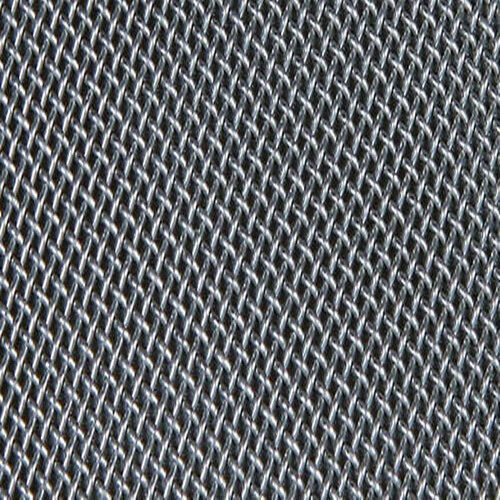

About Monel 400 Fine Wire Mesh

Monel 400 is a combination of nickel and copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% and is a versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments. Monel 400 is drawn to specific diameter wires and woven to certain specifications. Fine Wire Mesh is a mesh of wires combined together having fine holes on its surface. Monel Fine Wire mesh or wire cloth is thin woven wire mesh with a mesh from 11 to 500 500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch).Monel Fine Wire netting can have aperture from 0.0254 mm to 23.37 mm (0.001 inch to 0.92 inch) and when the wire diameter becomes thinner the aperture will be larger. Monel Fine Wire Mesh can be used in elevated temperature applications, due to its excellent functioning in higher temperatures. Monel Fine Wire mesh is a versatile wire mesh having wide applications in industrial, commercial and decoration.

Outstanding Corrosion Resistance

Monel 400 Fine Wire Mesh is engineered to withstand highly corrosive environments, making it a top choice for industries that require dependable durability. Its performance is unmatched in both acid and alkaline conditions, protecting equipment and maximizing operational lifespan even in harsh chemical and marine settings.

Versatility and Customization

This precision-woven mesh is available in customizable widths (0.5 to 2 meters) and lengths (up to 30 meters), with wire diameters ranging from 0.1 mm to 2 mm. Customers can select mesh styles, apertures, and edge finishes tailored to their specific filtration or separation needs, ensuring optimal results across a wide array of applications.

FAQs of Monel 400 Fine Wire Mesh:

Q: How is Monel 400 Fine Wire Mesh manufactured?

A: The mesh is manufactured using a precision weaving technique with Monel 400 alloy wires. During production, the wires are carefully woven into a fine mesh using the plain weave method, which provides uniformity and structural integrity. The mesh can be supplied either with cut or selvage edges, and it undergoes annealing to enhance durability and flexibility.Q: What benefits does Monel 400 Fine Wire Mesh offer in corrosive environments?

A: Monel 400 delivers exceptional corrosion resistance against acids, alkalis, and seawater, which makes it highly suitable for filtration, chemical processing, and marine applications. Its robust composition ensures minimal degradation and long service life in challenging industrial conditions.Q: Where is Monel 400 Fine Wire Mesh commonly used?

A: This mesh finds widespread application in sectors such as filtration, chemical processing, oil and gas, marine environments, and aerospace. Its resilience to corrosion and high tensile strength make it invaluable wherever reliable separation and protection from harsh substances are essential.Q: What customization options are available for this wire mesh?

A: Monel 400 Fine Wire Mesh can be tailored according to customer requirements, including wire gauge (1028 SWG), mesh width (0.52 meters), length (up to 30 meters), wire diameter (0.12 mm), aperture size (0.110 mm), edge type, and packing. Delivery can be arranged as per individual specifications.Q: When should I choose Monel 400 Fine Wire Mesh over other materials?

A: Opt for Monel 400 Fine Wire Mesh when your application demands superior chemical and corrosion resistance, as well as high tensile strength. It is particularly beneficial for environments involving exposure to acids, alkalies, seawater, and extreme temperatures up to 480C.Q: How is Monel 400 Fine Wire Mesh typically delivered and packaged?

A: Mesh is usually supplied in rolls or secured in wooden cases to ensure safe transport. The final packaging and delivery condition can be customized to meet client requirements, minimizing damage and preserving mesh quality during transit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Hastelloy Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Product Type : Wire Mesh

Material : Other

Nichrome A Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Polished

Color : Silver

Product Type : Other, Fine Wire Mesh

Material : Other, Nichrome A

Stainless Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Mill Finish

Color : Silver

Product Type : Other, Fine Wire Mesh

Material : Other, Stainless Steel 304

Bronze Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Mill Finish

Color : Bronze

Product Type : Other, Fine Wire Mesh

Material : Other, Phosphor Bronze

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry