Chain link Wire Mesh Conveyer Belt

Price 50 INR/ Unit

Chain link Wire Mesh Conveyer Belt Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Metal Alloys

- Application

- Other

- Color

- Silver

Chain link Wire Mesh Conveyer Belt Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Chain link Wire Mesh Conveyer Belt

Chain Link Wire Mesh Conveyor Beltis also known as Industrial Vibrating Screen, crusher screen, and Wire cloth.Wire Mesh Conveyor Beltsare widely applicable in different industries for their various applications and come in different sizes and dimensions as well as based on customized needs of our customers.Chain Link Wire Mesh Conveyor Beltare made for maximum strength steel to withstand heavy loading and with the durability to give you longer wear life. OurConveyor Beltsare available in a range of sizes from 8 x 4 (2.4 m x 1.2 m) to 8 x 24 (2.4 m x 7.3 m).The chain driven belt conveyor is almost the ultimate in traction and power, equalled only by the Plate Link or Slat conveyor types. It is the belt equivalent of the Chain Driven Roller Conveyor.Durable Construction with Advanced Materials

Crafted using premium metal alloys, the conveyer belt boasts a sturdy yet flexible structure. The coated surface treatment adds a layer of protection, making it resistant to wear and corrosion, even in demanding environments. Its silver color not only provides a clean appearance but also signals its quality and longevity.

Optimized Plain Mesh Design

The plain mesh style delivers a balanced combination of strength and openness, allowing for effective product flow and easy cleaning. This design makes the belt suitable for applications requiring ventilation, draining, or minimal contact with the surface, benefiting industries with strict hygiene standards.

FAQs of Chain link Wire Mesh Conveyer Belt:

Q: How is the chain link wire mesh conveyer belt used in industrial processes?

A: This conveyer belt is commonly used to transport various goods in manufacturing, packaging, and food processing operations. Its plain mesh allows for smooth movement of products, efficient draining, and easy cleaning.Q: What are the benefits of a plain mesh style in the conveyer belt?

A: The plain mesh style provides uniform openings, enabling airflow and quick draining. It supports easy maintenance and reduces product sticking, which is particularly useful in food and packaging industries.Q: When should you choose a coated surface treatment for wire mesh conveyer belts?

A: A coated surface treatment is ideal when you need added corrosion resistance and durability. This is especially recommended for environments exposed to moisture, chemicals, or high-temperature variations.Q: Where are these conveyer belts manufactured and supplied from?

A: The chain link wire mesh conveyer belts are manufactured, exported, and supplied by reputable companies in India, known for advanced metalworking and conveyer technology.Q: What process is used to manufacture the belt from metal alloys?

A: Manufacturers use precision weaving and coating techniques to form the plain mesh from metal alloys, followed by a coating application that further boosts its protective qualities.Q: How does the silver color benefit the conveyer belts performance?

A: The silver color, resulting from the metal alloy and coating finish, enhances corrosion visibility and cleanliness, making it suitable for industries requiring stringent hygiene and inspection standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Types of Wire Mesh Conveyor Belt Category

Food grade Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Mesh Style : Plain Mesh

Color : Silver

Surface Treatment : Coated

Wire Mesh Conveyer Belt with Baffle

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel (304/316), Mild Steel

Mesh Style : Woven Mesh

Color : Metallic Silver

Surface Treatment : Other, Galvanized/Polished

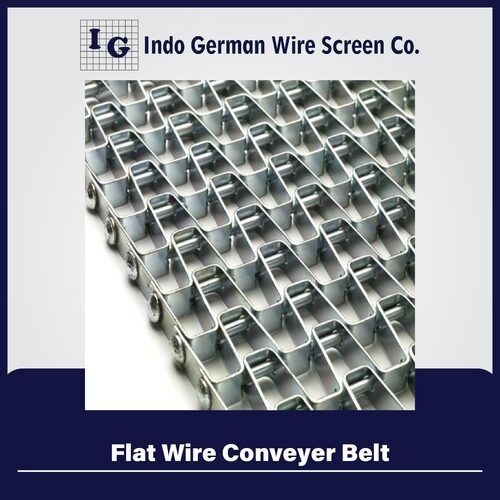

Flat Wire Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Mesh Style : Other , Flat wire mesh

Color : Silver Grey

Surface Treatment : Galvanized

Custom Edge Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Mesh Style : Plain Mesh

Color : Black

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry