Food grade Wire Mesh Conveyor Belt

Price 50 INR/ Unit

Food grade Wire Mesh Conveyor Belt Specification

- Length

- As per requirement

- Hole Shape

- Rectangular

- Surface Treatment

- Coated

- Aperture

- Standard/Custom

- Wire Gauge

- Customizable

- Product Type

- Wire Mesh

- Mesh Type

- Conveyor Belt Mesh

- Mesh Style

- Plain Mesh

- Material

- Metal Alloys

- Alloy

- Stainless Steel/Other Alloys

- Application

- Other

- Dimensions

- Standard/Customized as per demand

- Wire Diameter

- 1.5 mm - 4 mm

- Weight

- Varies with specifications

- Color

- Silver

Food grade Wire Mesh Conveyor Belt Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Food grade Wire Mesh Conveyor Belt

Food grade Wire Mesh Conveyor Beltare widely used conveyor belts in the food sector (tea, sugar industry) that are suitable for handling food items by directly moving food on the belt surface.Food packaging conveyor belts do not transfer colour contamination or any odour to the food materials while handling, preventing bacterial growth, safeguarding the possibility of water collection, and providing uniform loads. Food grade Wire Mesh Conveyor Belt also known as an ideal choice for applications requiring durability and an open belt design on flat carrying surface since it is a strong, lightweight, positively driven belt. Food grade Wire Mesh Conveyor Belt also has a high strength-to-weight ratio improving their energy efficiency.We offer an exclusive range ofFood grade Wire Mesh Conveyor Beltsat unmatched quality and market leading prices.

Exceptional Temperature Resistance

Designed to withstand operational temperatures up to 600C, these wire mesh conveyor belts provide consistent performance in high-heat processes typical of baking, drying, and chemical treatments. Their robust alloy construction mitigates risks of deformation, making them suitable for various industrial applications.

Customizable for Diverse Applications

With options for wire diameter, belt edge type, mesh style, and dimensions, these conveyor belts can be adapted to specific requirements across industries. Whether you need rectangular or custom-shaped apertures, or a particular alloy, our manufacturing flexibility ensures youll receive optimal solutions.

Food Grade Compliance

Certified for food contact and industrial compliance, these belts meet stringent hygiene standards essential for food processing and pharmaceutical environments. Their easy-to-clean design, rust resistance, and silver finish streamline maintenance and reduce downtime, enhancing operational efficiency.

FAQs of Food grade Wire Mesh Conveyor Belt:

Q: How do I select the appropriate wire mesh conveyor belt for my specific process?

A: Choosing the right conveyor belt involves understanding your temperature requirements, material type, desired open area, and the nature of the product being transported. Our experts guide you through the selection process, ensuring your belt type, edge design, and wire gauge match your environmental and operational needs.Q: What benefits does the welded, chain link, or hook edge design offer for conveyor belts?

A: Each edge type offers distinct advantages: welded edges enhance structural integrity for continuous flow, chain links provide modular flexibility and easy repair, while hook edges facilitate quick installation and interchangeability. Your choice depends on application demands and ease of maintenance priorities.Q: When is on-site installation support available for my conveyor belt setup?

A: On-site installation and support are available upon request for both domestic and export projects. Our team assists with fitting, alignment, and operational setup to ensure your conveyor belt integrates seamlessly into your system, minimizing installation downtime.Q: Where can these food grade wire mesh conveyor belts be used?

A: These belts are suitable for the food industry, pharmaceuticals, and chemical processing. Their high tensile strength and corrosion resistance make them ideal for baking, cooling, washing, drying, and packaging tasks in environments that require compliance with food-grade standards.Q: What is the process involved in customizing wire gauge and belt dimensions?

A: Customization begins by specifying wire diameter, mesh aperture, belt width and length, and preferred material. We offer recommendations based on your application, manufacturing the belt to your exact requirements, including standard or unique mesh styles and hole shapes.Q: How do you ensure the conveyor belts are easy to clean and maintain?

A: The metal alloys and coated surface treatments provide excellent resistance to corrosion and rust, while the plain mesh design and silver finish enable straightforward cleaning. This facilitates compliance with hygiene standards and significantly reduces maintenance efforts over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Types of Wire Mesh Conveyor Belt Category

Wire Mesh Conveyer Belt with Baffle

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic Silver

Mesh Style : Woven Mesh

Surface Treatment : Other, Galvanized/Polished

Material : Other, Stainless Steel (304/316), Mild Steel

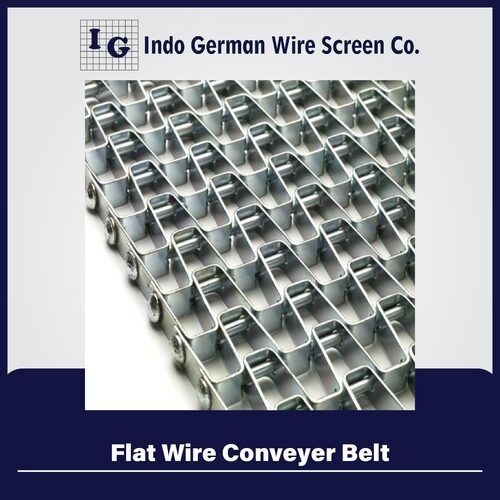

Flat Wire Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver Grey

Mesh Style : Other , Flat wire mesh

Surface Treatment : Galvanized

Material : Other, Mild Steel

Custom Edge Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Black

Mesh Style : Plain Mesh

Surface Treatment : Coated

Material : Steel

Wicket Edge Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Style : Plain Mesh

Surface Treatment : Coated

Material : Steel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry