Copper Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Copper Reverse Dutch Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Copper Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Copper

- Application

- Other

- Color

- Copper

Copper Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Copper Reverse Dutch Weave Wire Mesh

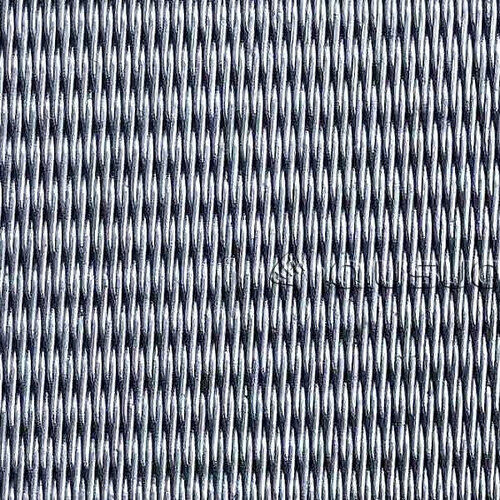

Copper Reverse Dutch Weave Wire Meshhas more thin warp wires and fewer, but larger, weft wires as this structure provides a high degree of stability and optimal resistance to high pressure.Reverse Dutch weave wire meshis specially designed for filtering and has a very high level of mechanical load and a high flow and porosity level.The type of cloth is mechanically highly sturdy with a high throughput and it does particularly well in high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are vital.We offer an exclusive range ofCopper Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Advanced Mesh Design

The reverse Dutch weave technique provides superior strength and precise filtration capabilities, making the copper wire mesh ideal for demanding industrial processes where reliability is paramount.

High-Quality Copper Material

Manufactured from high-grade copper, this wire mesh guarantees excellent conductivity, long-term durability, and resistance to atmospheric corrosion. The copper finish adds an aesthetic appeal and maximizes energy efficiency in relevant applications.

Versatile Applications

Widely used for filtration, screening, and decorative purposes, copper wire mesh finds its place in chemical, pharmaceutical, and architectural sectors across India, owing to its adaptability and performance advantage.

FAQs of Copper Reverse Dutch Weave Wire Mesh:

Q: How is Copper Reverse Dutch Weave Wire Mesh manufactured?

A: This wire mesh is produced using premium copper wires woven in a reverse Dutch weave pattern, which involves a thinner wire in the warp and a thicker wire in the weft. The process ensures a tightly woven plain mesh with precise filtration capabilities.Q: What are the advantages of using coated copper wire mesh?

A: The coated surface treatment on copper wire mesh offers improved resistance to oxidation, extends the meshs service life, and enhances its performance in corrosive environments, making it suitable for industrial uses.Q: When should I choose Copper Reverse Dutch Weave Wire Mesh over other mesh types?

A: Select Copper Reverse Dutch Weave Wire Mesh when your application demands fine yet sturdy filtration, high conductivity, and corrosion resistance, such as in chemical processing, filtration, or architectural projects.Q: Where is this copper wire mesh typically utilized?

A: It is popular in sectors like chemical, pharmaceutical, environmental filtration, architectural decors, and electromagnetic shielding, particularly in India where suppliers, manufacturers, exporters, and traders provide customized meshes.Q: What is the process for sourcing Copper Reverse Dutch Weave Wire Mesh in India?

A: You can obtain this mesh by reaching out to established manufacturers, exporters, or suppliers based in India who offer tailored solutions and technical guidance for specific application requirements.Q: How can this mesh benefit my industrial filtration system?

A: Its unique reverse Dutch weave style delivers precise filtration, enhanced durability, and reliable performance in corrosive environments, contributing to improved operational efficiency and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

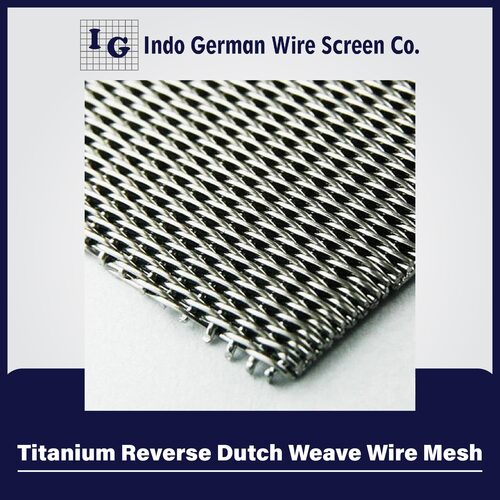

Titanium Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Silver

Material : Other

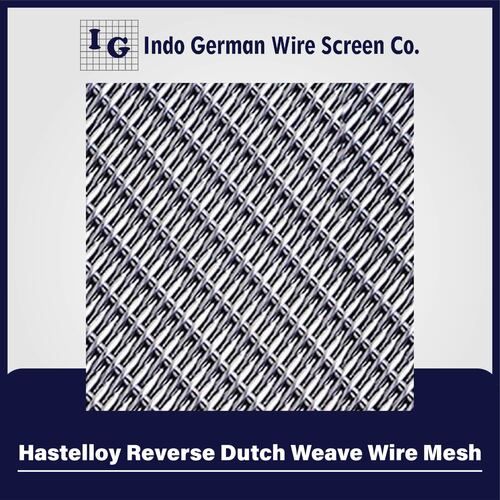

Hastelloy Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Silver

Material : Other, Hastelloy

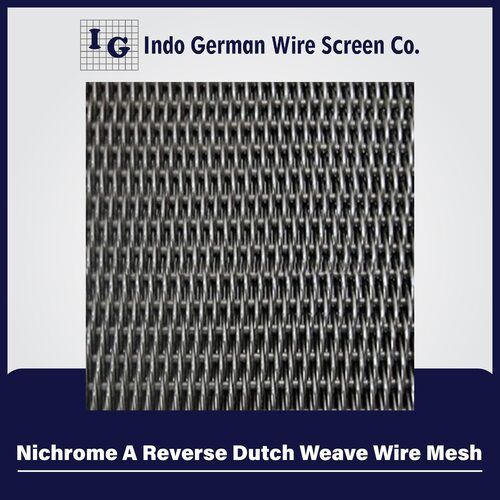

Nichrome A Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Silver

Material : Other, Nichrome

Monel 400 Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Silver

Material : Other, Monel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry