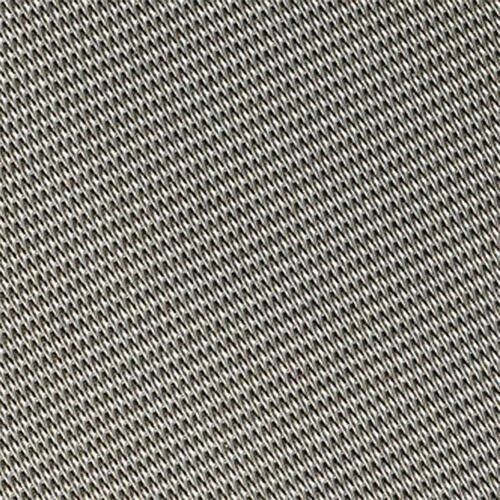

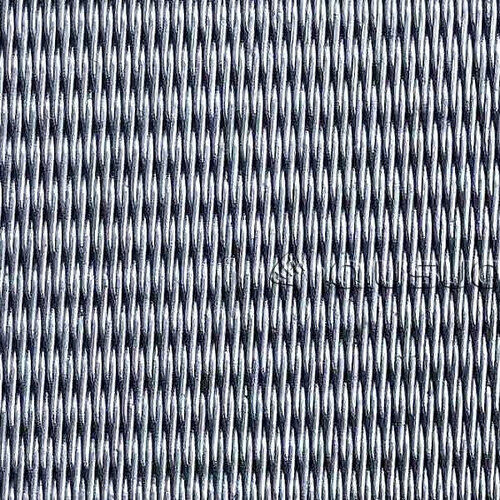

Monel 400 Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Monel 400 Reverse Dutch Weave Wire Mesh Specification

- Length

- 15 m, 30 m, or custom lengths

- Hole Shape

- Rectangular

- Aperture

- 0.02 mm - 2.03 mm

- Wire Gauge

- 30 Gauge - 10 Gauge

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Monel

- Alloy

- Monel 400

- Dimensions

- Available in custom sizes as per requirement

- Wire Diameter

- 0.025 mm - 2 mm

- Weight

- As per size and gauge

- Color

- Silver

- Standard Roll Width

- 1 m, 1.22 m, or as required

- Form

- Rolls or cut pieces

- Edge Finish

- Plain and welded edges available

- Operating Temperature

- Up to 550°C

- Tensile Strength

- High, suitable for heavy-duty applications

- Port of Dispatch

- Mumbai

- Opening Micron

- 20 microns to 2000 microns

- Corrosion Resistance

- Excellent in acidic and alkaline environments

- Weave Type

- Reverse Dutch Weave

Monel 400 Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Monel 400 Reverse Dutch Weave Wire Mesh

Monel 400 is a combination of nickel and copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% and is versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments. Compared to the common stainless steel wire mesh, monel has a high melting point of 1300 F to 1350 F and strength superior to unalloyed nickel. Due to this exceptional quality, monel is being used inside high-temperature vessels and petroleum applications.The type of cloth is mechanically highly sturdy with a high throughput and it does particularly well in high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are vital.We offer an exclusive range ofMonel 400 Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Superior Corrosion Resistance

Constructed from Monel 400 alloy, the Reverse Dutch Weave Wire Mesh offers excellent resistance to acids, alkalis, and other corrosive environments. This ingrained durability makes the mesh an optimal choice for long-term use in chemical processing plants, marine installations, and demanding filtration systems.

Precision Filtration Performance

The mesh is available in openings ranging from 20 microns to 2000 microns, supporting a wide array of filtration requirements. Its Reverse Dutch Weave style delivers enhanced strength, stability, and retention for fine particles, contributing to efficient filtration processes in industrial applications.

Flexible Sizing and Edge Options

Customers can select from standard roll widths of 1 m and 1.22 m or request custom sizes to suit specific operational needs. Additionally, you can choose between plain or welded edge finishes for the most appropriate installation outcome. Mesh rolls and cut pieces ensure adaptable integration into diverse projects.

FAQs of Monel 400 Reverse Dutch Weave Wire Mesh:

Q: How does the Reverse Dutch Weave design benefit industrial filtration applications?

A: The Reverse Dutch Weave style provides superior strength, enhanced flow rates, and efficient retention of fine particles, making it highly beneficial for industrial filtration in chemical processing, oil & gas, and heat exchangers.Q: What is the process for ordering custom sizes or dimensions of Monel 400 wire mesh?

A: To order custom sizes, clients can specify their preferred aperture, wire diameter, roll width, length, and edge finish. Custom forms can be manufactured and dispatched from Mumbai to meet unique operational requirements.Q: When is Monel 400 Reverse Dutch Weave Mesh recommended over other mesh types?

A: This mesh is recommended when exceptional corrosion resistance and high tensile strength are required, such as in heavy-duty filtration, marine applications, or environments involving aggressive chemicals and high temperatures.Q: Where is Monel 400 Reverse Dutch Weave Mesh typically used?

A: The wire mesh is widely used in chemical processing, filtration units, oil & gas extraction, marine installations, and heat exchangers, where durability and performance in corrosive conditions are critical.Q: What are the available surface treatments and their benefits?

A: Monel 400 mesh comes with coated surface treatments, which further enhance durability and corrosion resistance, extending its lifecycle in harsh operational settings.Q: How can customers ensure they select the correct micron size and wire gauge for their application?

A: Customers should consider the particle size to be filtered, desired flow rates, and the operating environment. Consultation with our experts helps determine the optimal opening micron and wire gauge aligned with application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

Nickel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other, Filtration, Chemical Processing, Battery Electrode, Gas and Liquid Separation

Product Type : Wire Mesh

Material : Other

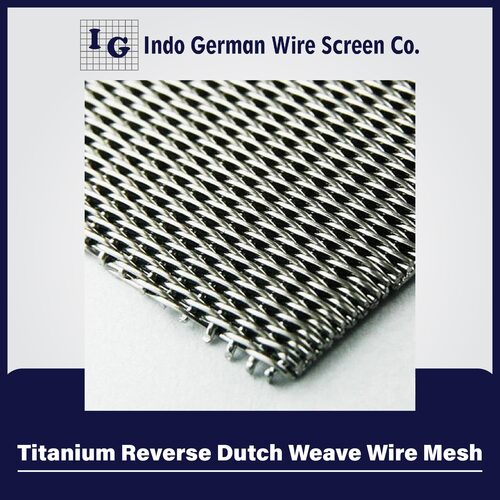

Titanium Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Product Type : Wire Mesh

Material : Other

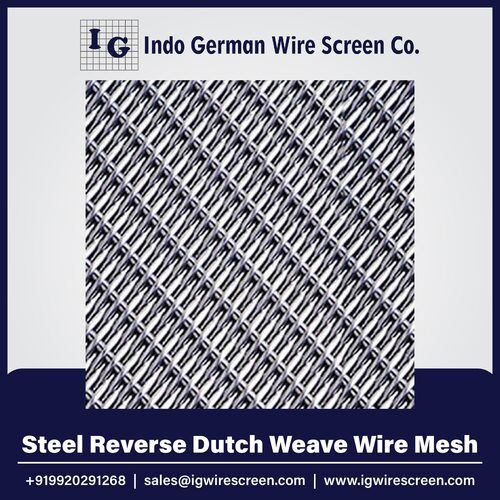

Steel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Product Type : Wire Mesh

Material : Steel

Iron Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Product Type : Wire Mesh

Material : Iron

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry