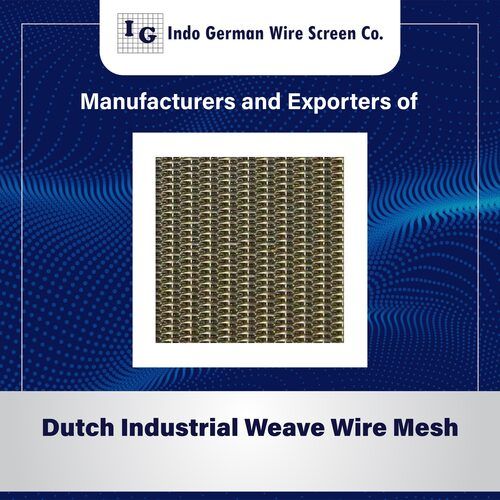

Dutch Industrial Weave Wire Mesh

Price 1000 INR/ Foot

Dutch Industrial Weave Wire Mesh Specification

- Aperture

- 0.02 mm to 2 mm

- Wire Gauge

- 16 to 28 SWG

- Length

- 30 meters (standard roll length)

- Hole Shape

- Rectangular

- Surface Treatment

- Galvanized, Stainless Steel, or Plain

- Product Type

- Dutch Industrial Weave Wire Mesh

- Mesh Type

- Woven Wire Mesh

- Mesh Style

- Industrial Weave

- Material

- Stainless Steel, Brass, Copper, Mild Steel

- Alloy

- SS304, SS316, Brass, Copper

- Application

- Filtration, Sieving, Industrial, Chemical, Food Processing

- Dimensions

- Width: 0.6 m to 1.5 m

- Wire Diameter

- 0.018 mm to 2 mm

- Weight

- Varies by specifications, approx. 1545 kg per roll

- Color

- Silver / Metallic Grey

- Custom Sizes

- Available on request

- Edge Type

- Plain or Selvage

- Opening Size

- 0.02 mm and above

- Tensile Strength

- High (industrial grade)

- Corrosion Resistance

- High (for Stainless Steel mesh)

- Packing

- Rolls wrapped in moisture-proof paper

- Temperature Resistance

- Up to 800°C (Stainless Steel)

- Weave Type

- Dutch Weave

Dutch Industrial Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit (L/C), Cheque, Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia

About Dutch Industrial Weave Wire Mesh

The Plain Dutch Weave Wire Mesh or Wire filter screen is woven the same way as the plain weave wire mesh. The exception of the plain dutch weave wire mesh is that the warp wires are heavier than the shute wires. Dutch Weave wire mesh is produced by the use of coarse mesh (mesh wire, woven wire mesh, wire mesh basket) in the warp and a fine mesh with relatively smaller wire in the fill. The shape and position of the openings aid particle retention and increase filter cake formation.

Superior Dutch Weave Construction

The Dutch weave technique delivers exceptional precision and strength, making the mesh suitable for fine filtration and separation tasks. This specialized pattern enhances particle retention capabilities, ensuring reliable performance in industrial and chemical manufacturing sectors.

Customizable for Diverse Industries

Customers can request specific sizes and choose among materials like stainless steel, brass, copper, and mild steel. The mesh is offered in various apertures, wire gauges, and surface treatmentsmeeting diverse application needs, from food processing to heavy-duty filtration.

Reliable Performance in Extreme Conditions

Designed to withstand high temperatures (up to 800C for stainless steel) and corrosive environments, Dutch Industrial Weave Wire Mesh maintains its integrity and efficiency. Standard rolls are packaged in moisture-proof wrapping for added longevity during storage and transport.

FAQs of Dutch Industrial Weave Wire Mesh:

Q: How is Dutch Industrial Weave Wire Mesh used in industrial applications?

A: This wire mesh is commonly utilized for filtration, sieving, and separation processes in industries such as chemical processing and food production, thanks to its fine aperture range and robust structure.Q: What materials are available for Dutch Weave Wire Mesh?

A: The mesh can be manufactured from stainless steel (SS304, SS316), brass, copper, or mild steel, allowing users to select the best option for specific environmental or operational requirements.Q: When should I choose plain or selvage edges for the mesh?

A: Plain edges are ideal for general applications, whereas selvage edges are recommended for improved durability, especially in high-tension installations or frequent handling scenarios.Q: Where can custom sizes and dimensions be requested for this mesh?

A: Custom orders can be placed through the mesh exporter, manufacturer, supplier, or trader listed, typically based in India. Clients can specify their desired width, length, and wire diameter.Q: What process is involved in packing Dutch Weave Wire Mesh?

A: Each roll is carefully wrapped in moisture-proof paper to preserve the meshs surface quality and integrity during storage and shipping, thus reducing the risk of corrosion or contamination.Q: How does high tensile strength benefit industrial users?

A: With its industrial-grade tensile strength, the mesh endures mechanical stresses and maintains structural stability, ensuring consistent performance across demanding filtration and sieving tasks.Q: What are the advantages of the meshs temperature and corrosion resistance?

A: The mesh withstands elevated temperatures up to 800C and resists corrosionespecially when made from stainless steelmaking it highly advantageous for harsh environments found in chemical and manufacturing industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weave Wire Mesh Category

Plain Industrial Weave Wire Mesh

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Type : Other , Woven Mesh

Color : Silver

Mesh Style : Other , Plain Industrial Weave

Hole Shape : Other , Square

Reverse Dutch Weave Wire Mesh

Mesh Type : Wire Mesh, Other

Color : Silver

Mesh Style : Reverse Dutch Weave, Other

Hole Shape : Rectangular, Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry