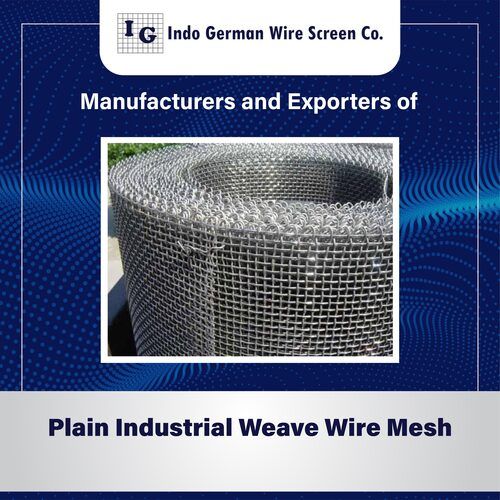

Plain Industrial Weave Wire Mesh

Price 1000 INR/ Foot

Plain Industrial Weave Wire Mesh Specification

- Hole Shape

- Square

- Aperture

- 0.3 mm to 20 mm

- Surface Treatment

- Galvanized / Uncoated

- Wire Gauge

- 10 to 30 SWG

- Length

- Available in standard rolls (15 m, 30 m) or as per requirement

- Product Type

- Plain Weave Wire Mesh

- Mesh Type

- Woven Mesh

- Mesh Style

- Plain Industrial Weave

- Material

- Stainless Steel / Mild Steel / Galvanized Iron

- Alloy

- SS304 / SS316 / Mild Steel / GI

- Application

- Filtration, Sieving, Industrial Screening, Protection, Fencing

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.25 mm to 3 mm

- Weight

- Variable as per mesh size and material

- Color

- Silver

Plain Industrial Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 50 Feet

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Plain Industrial Weave Wire Mesh

Plain Weave Wire Mesh is the most commonly used weave. Plain Weave Wire Mesh has a square opening thats why it is also called as Square Wire Mesh. Each weft wire passes alternately over and under each warp wire and vice versa. Warp and weft wire diameters are generally the same. Plain weave wire meshes are available with apertures from 10.7mm (2 mesh) to 0.05mm (325 mesh). Plain Weave wire mesh could be Woven and Welded.

Features of Plain Weave Wire Mesh

- Square weaves

- Straight through square holes

- Thin and flexible.

- Separation and classification of solid particles.

- Very high flow rates.

Superior Corrosion and Temperature Resistance

This wire mesh is manufactured using stainless steel and galvanized iron, offering high corrosion resistance even in challenging industrial environments. Its temperature resilience, dependent on the material, allows operation up to 700C, making it ideal for applications where both metallic stability and longevity are needed.

Versatile Customization and Applications

Available in standard rolls of 15 m and 30 m, or customized lengths, the mesh is tailored to meet specific project requirements. Its adaptability in aperture size, wire diameter, and finish facilitates usage across filtration, screening, fencing, and protection in industrial settings.

Precision Weaving and Smooth Finishes

Featuring a plain weave for consistent structure, the mesh is offered with either cut or selvage edges. The smooth surface finish enhances functionality, minimizing snags and ensuring easy cleaning and handling across diverse usage scenarios.

FAQs of Plain Industrial Weave Wire Mesh:

Q: How is the plain industrial weave wire mesh manufactured and packed?

A: The wire mesh is produced using a plain weave technique, ensuring consistent structure. It is packed in rolls or bundles, and custom packing options are available based on project specifications.Q: What are the benefits of using stainless steel or galvanized iron for this mesh?

A: Stainless steel and galvanized iron provide superior resistance to corrosion and high temperatures (up to 700C), increasing the meshs lifespan and reliability in demanding industrial uses.Q: When should I choose cut edge versus selvage edge for my wire mesh?

A: Cut edges are suitable for general-purpose installations, while selvage edges offer additional stability and prevent unraveling, making them ideal for applications requiring extra durability.Q: Where is plain industrial weave wire mesh typically used?

A: This mesh is widely deployed in filtration systems, industrial sieving, protective barriers, and fencing, making it essential in sectors such as manufacturing, mining, and infrastructure.Q: What is the process for customizing mesh dimensions and finishes?

A: Customers can specify required mesh aperture, wire diameter, length, and surface treatment (galvanized or uncoated) during ordering. Suppliers accommodate custom requests for edge type and finishing to meet varying application needs.Q: How does the mesh perform under extreme temperatures or corrosive environments?

A: Depending on the chosen material (such as SS304 or SS316), the mesh withstands high temperatures up to 700C and maintains integrity in corrosive settings, ensuring long-term performance.Q: Can the wire mesh be used for both indoor and outdoor applications?

A: Yes, with its corrosion-resistant properties and smooth finish, the mesh performs reliably indoors for industrial screening and outdoors for protection and fencing, regardless of environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weave Wire Mesh Category

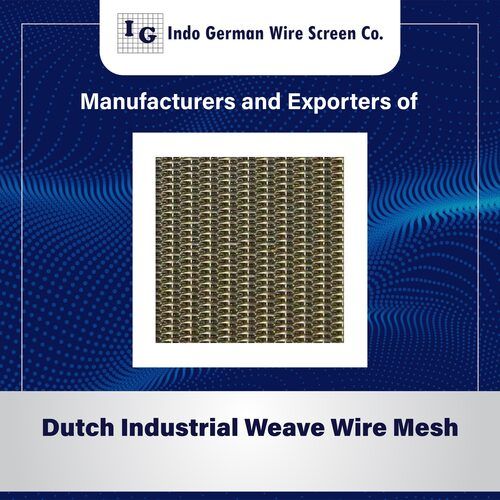

Dutch Industrial Weave Wire Mesh

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Product Type : Other, Dutch Industrial Weave Wire Mesh

Hole Shape : Other , Rectangular

Mesh Style : Other , Industrial Weave

Color : Silver / Metallic Grey

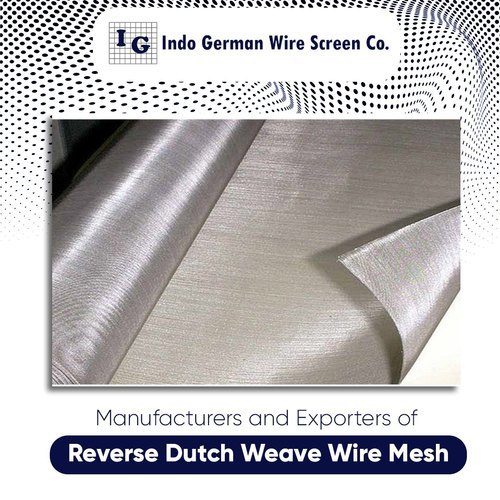

Reverse Dutch Weave Wire Mesh

Product Type : Other, Reverse Dutch Weave Wire Mesh

Hole Shape : Rectangular, Other

Mesh Style : Reverse Dutch Weave, Other

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry