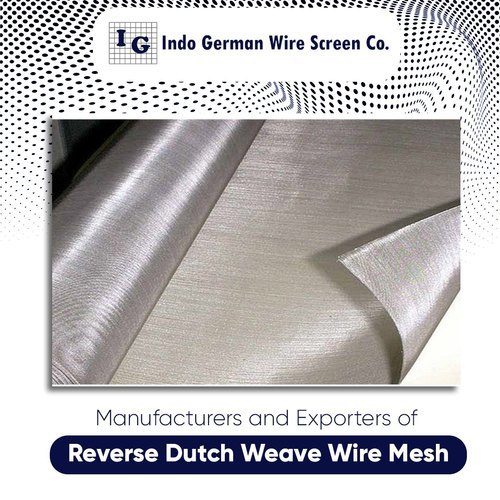

Reverse Dutch Weave Wire Mesh

Reverse Dutch Weave Wire Mesh Specification

- Hole Shape

- Rectangular

- Product Type

- Reverse Dutch Weave Wire Mesh

- Mesh Type

- Wire Mesh

- Mesh Style

- Reverse Dutch Weave

- Color

- Silver

About Reverse Dutch Weave Wire Mesh

Maximum filtering effectiveness is guaranteed by the distinctive weave pattern of our Reverse Dutch Weave Wire Mesh. It is an excellent choice for crucial filtration duties since it excels at holding particles and pollutants. This wire mesh is made from premium stainless steel and is designed to last, providing great durability and corrosion resistance. It is a dependable option for demanding applications since it can tolerate adverse weather conditions. No matter what business you work in-pharmaceuticals, food and beverage, oil and gas, or chemicals-our Reverse Dutch Weave Wire Mesh may satisfy your requirements.

Innovative Weaving for Superior Filtration

Reverse Dutch Weave Wire Mesh is engineered using a specialized weaving process. This method interlaces wires in a way that provides a robust structure, ideal for filtering fine particles while maintaining high mechanical strength. The rectangular and custom-designed holes enhance versatility for various industrial applications.

Wide Application Across Industries

Reverse Dutch Weave Wire Mesh is widely utilized in industries such as pharmaceuticals, chemicals, food processing, and water treatment. Its corrosion resistance and durability, coupled with excellent filtration performance, make it highly suitable for critical operations. As a trusted exporter and manufacturer in India, we deliver high-quality mesh tailored to specific requirements.

FAQs of Reverse Dutch Weave Wire Mesh:

Q: How is Reverse Dutch Weave Wire Mesh manufactured?

A: Reverse Dutch Weave Wire Mesh is produced using a weaving technique where thicker warp wires and a higher number of thinner weft wires are interlaced to create a strong, tightly woven mesh. This results in rectangular or custom hole shapes that deliver optimal filtration and durability.Q: What are the typical uses of Reverse Dutch Weave Wire Mesh?

A: The mesh is mainly used for filtration, separation, and material sieving in industries like chemical processing, water treatment, pharmaceuticals, and food production due to its robust structure and fine filtration capability.Q: When should I choose Reverse Dutch Weave Wire Mesh over other types?

A: Opt for Reverse Dutch Weave Wire Mesh when your application demands high mechanical strength, resistance to clogging, and the ability to filter very fine particles, especially in high-pressure or corrosive environments.Q: Where can this wire mesh be installed or applied?

A: Reverse Dutch Weave Wire Mesh can be installed in filtration systems, separation equipment, industrial sieves, and screening machines in plants related to water treatment, pharmaceuticals, chemicals, and food processing, among others.Q: What benefits does Reverse Dutch Weave Wire Mesh offer compared to standard meshes?

A: This mesh delivers superior particle retention, enhanced flow rates due to its weave structure, and excellent resistance to wear and corrosion, making it more reliable for demanding industrial settings.Q: How is the silver color achieved on the mesh?

A: The silver appearance primarily comes from the use of high-quality stainless steel or similar alloys. In some cases, surface treatments are applied to ensure additional luster and corrosion protection without affecting its filtration performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Weave Wire Mesh Category

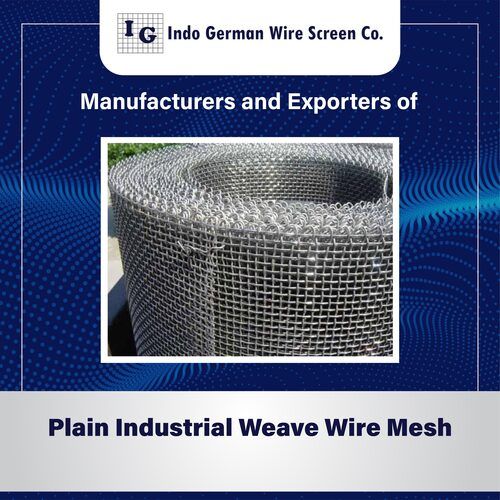

Plain Industrial Weave Wire Mesh

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet

Alloy : SS304 / SS316 / Mild Steel / GI

Color : Silver

Wire Gauge : 10 to 30 SWG

Surface Treatment : Other, Galvanized / Uncoated

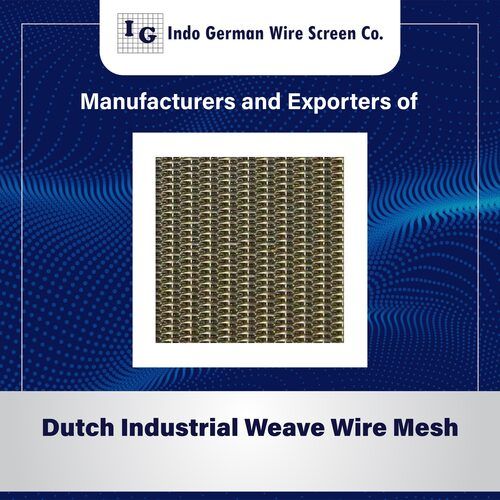

Dutch Industrial Weave Wire Mesh

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Alloy : SS304, SS316, Brass, Copper

Color : Silver / Metallic Grey

Wire Gauge : 16 to 28 SWG

Surface Treatment : Other, Galvanized, Stainless Steel, or Plain

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry