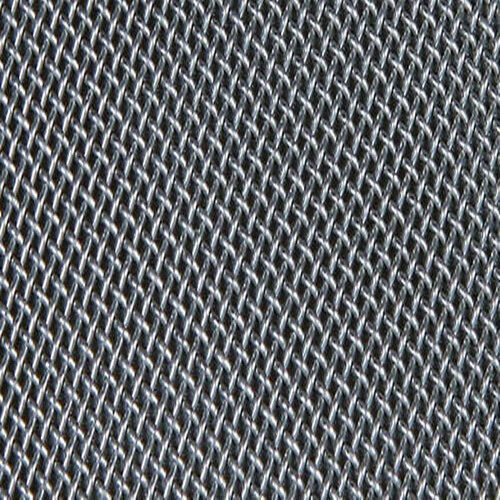

Stainless Steel Fine Wire Mesh

Price 50 INR/ Unit

Stainless Steel Fine Wire Mesh Specification

- Aperture

- 0.3 mm

- Length

- 30 Meter Roll

- Hole Shape

- Square

- Surface Treatment

- Mill Finish

- Wire Gauge

- 30 Gauge

- Product Type

- Fine Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Woven

- Material

- Stainless Steel 304

- Alloy

- SS304

- Application

- Filtration, Sieving, Insect Screen, Laboratory Use

- Dimensions

- 1 Meter Width

- Wire Diameter

- 0.25 mm

- Weight

- Approx. 2 kg per roll

- Color

- Silver

- Temperature Range

- -100°C to 800°C

- Magnetic Property

- Non-Magnetic

- Tensile Strength

- High

- Corrosion Resistance

- Excellent

- Weave Type

- Plain Weave

- Number of Meshes per Inch

- 80 Mesh

- Opening Size

- 0.3 mm

- Edge Type

- Open Edges

- Packing Type

- Roll Form

- Usage Environment

- Indoor and Outdoor

About Stainless Steel Fine Wire Mesh

Stainless steel is an alloy of iron with chromium and is the most comprehensive material having indispensable properties. Stainless Steel has properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance. Stainless Steel has high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio. Stainless steel also comprises variable quantities of carbon, silicon, manganese, and other elements such as nickel and molybdenum can be added to impart other advantageous properties such as enhanced formability and increased corrosion resistance. Fine Wire Mesh is a mesh of wires combined together having fine holes on its surface. Stainless Steel Fine Wire mesh or wire cloth is thin woven wire meshes with mesh from 11 to 500 500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch).Exceptional Durability and Versatility

Manufactured from premium SS304 stainless steel, this fine wire mesh resists corrosion and extreme temperatures, making it ideal for both indoor and outdoor applications. Its robust nature allows for use in filtration, sieving, and even laboratory setups where reliability is crucial.

Precision Engineering for Exact Performance

Each mesh features an 80 per inch configuration with a consistent 0.3 mm aperture, ensuring reliable and uniform results in critical applications. The plain weave and fine 30-gauge wires provide excellent flow control and effective screening in a lightweight design.

FAQs of Stainless Steel Fine Wire Mesh:

Q: How is the stainless steel fine wire mesh commonly installed or fixed in place?

A: The mesh can be easily mounted or framed using standard fixing methods such as clamps, adhesives, or by welding the open edges. Its flexibility allows it to be cut and shaped to suit specific fittings or enclosures as required by the application.Q: What makes SS304 stainless steel mesh beneficial for both indoor and outdoor use?

A: SS304 stainless steel offers excellent corrosion resistance and high tensile strength, making the mesh highly durable in a variety of environments. It withstands moisture, chemicals, and extreme temperatures from -100C to 800C, ensuring performance both indoors and outdoors.Q: When should I use this fine wire mesh for filtration or sieving?

A: This mesh is ideal for applications requiring precise particle size control, such as laboratory filtration, industrial sieving, or as an insect screen. Its consistent 0.3 mm aperture and fine 80 mesh structure make it effective for separating fine materials or preventing pest intrusion.Q: Where is this mesh typically utilized in laboratory environments?

A: In laboratories, the mesh is frequently used for sample filtration, air or fluid sieving, and as protective screens in equipment. Its non-magnetic and corrosion-resistant properties are particularly valued in sensitive analytical or chemical processes.Q: What process ensures the meshs durability and quality during manufacturing?

A: The mesh is produced using a plain weaving process and is given a mill finish, ensuring smooth edges and consistent aperture. Rigorous quality checks verify tensile strength, accurate mesh count, and uniform aperture size for each roll before shipment.Q: How does the wire gauge and diameter affect the meshs performance?

A: With a 30-gauge, 0.25 mm diameter wire, the mesh achieves a balance between fine filtration and durability. This thin, strong wire maximizes open area for airflow or fluid flow while maintaining enough strength for repeated use and easy handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Brass Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Color : Golden

Monel 400 Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Monel 400

Mesh Style : Woven Mesh

Product Type : Other, Fine Wire Mesh

Color : Metallic Grey

Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Mesh Style : Woven Mesh

Product Type : Other, Fine Wire Mesh

Color : Silver

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Highpurity Tungsten (>99.95%)

Mesh Style : Other , Woven

Product Type : Other, Fine Wire Mesh

Color : Silvergrey

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry