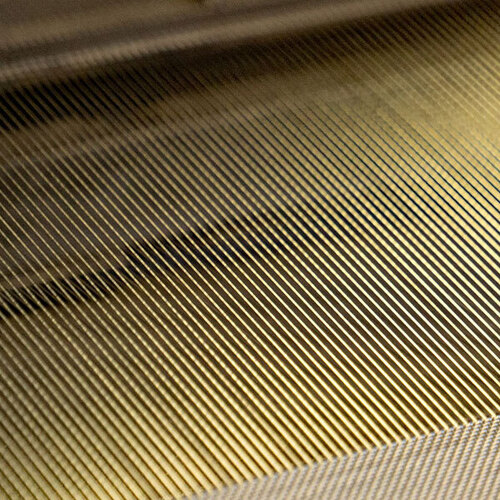

Inconel Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Inconel Five Shed Twill Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Inconel Wire Mesh

- Material

- Inconel

- Application

- Other

- Color

- Silver

Inconel Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Five Shed Twill Weave Wire Mesh

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added into Inconel as per requirement and grade. Inconel are useful in a wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.Inconel Five Shed Twill weave wire meshis a welded wire mesh panel precisely manufactured by knitting thin diameter wires to form a square mesh hole. TheInconel Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.We offer an exclusive range ofInconel Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Exceptional Performance in Extreme Environments

This Inconel wire mesh stands out for its exceptional strength, heat resistance, and ability to withstand corrosive conditions. The five-shed twill weave ensures uniform structure and reliable filtration, making it suitable for chemical, aerospace, and petrochemical industries. Its coated surface further boosts longevity and ease of maintenance.

Trusted Exporter and Supplier from India

We are recognized as a leading exporter, manufacturer, supplier, and trader of Inconel Five Shed Twill Weave Wire Mesh in India. Our advanced manufacturing techniques and stringent quality control guarantee a mesh that meets global standards for both industrial and commercial use.

FAQs of Inconel Five Shed Twill Weave Wire Mesh:

Q: How is the five shed twill weave process applied to the Inconel wire mesh?

A: The five shed twill weave process involves interlacing Inconel wires in a specific pattern that gives the mesh enhanced structural integrity and flexibility. This method ensures precise pore distribution, making the mesh suitable for high-performance filtration and separation.Q: What are the primary uses of Inconel Five Shed Twill Weave Wire Mesh?

A: This wire mesh is commonly used in industrial filtration, chemical processing, aerospace shielding, and high-temperature environments. Its robustness and corrosion resistance make it a preferred option for critical operations requiring reliability.Q: When should I choose Inconel wire mesh over other materials?

A: Inconel wire mesh is recommended when your application demands resistance to extreme temperatures, chemical corrosion, or mechanical stress. It outperforms conventional meshes in tough operating conditions, providing extended service life.Q: Where can Inconel Five Shed Twill Weave Wire Mesh be sourced in India?

A: You can procure this mesh from reputable exporters, manufacturers, suppliers, and traders located throughout India. We offer customized solutions to meet specific client needs, ensuring fast delivery and consistent product quality.Q: What benefits does surface coating provide to the Inconel wire mesh?

A: The coated surface treatment enhances the meshs resistance to oxidation, wear, and environmental degradation. It contributes to easier cleaning, improved aesthetics, and prolonged operating lifespan, especially in demanding industrial settings.Q: How can the mesh be installed and maintained for optimal performance?

A: Installation involves precise fitting based on the intended application, ensuring the mesh is securely fixed and properly aligned. Regular inspection and cleaning of the coated surface help maintain performance, while the meshs inherent durability minimizes maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Color : Silver

Surface Treatment : Coated

Product Type : Wire Mesh

Bronze Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Bronze

Color : Bronze

Surface Treatment : Coated

Product Type : Wire Mesh

Steel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Color : Silver Grey

Surface Treatment : Coated

Product Type : Wire Mesh

Iron Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Iron

Color : Silver

Surface Treatment : Coated

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry