Inconel Square Wire Mesh

Price 50 INR/ Unit

Inconel Square Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Inconel Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Inconel

- Color

- Silver

Inconel Square Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Square Wire Mesh

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added in to Inconel as per requirement and grade. Inconel are useful in wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.Square wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.Inconel Square Wire Meshis in great demand and widely used for security purposes, sifting, machinery guard, sign panel, windows and hardware fittings, protective enclosure in cages, poultry farms, power plants, various factories, house fencing, zoos and many other areas.Inconel Square Wire Meshis extensively used for sieving, particle separation, filtering, safety and equipment protection, window screen, food processing industries, infill panels, and many more uses and find applications in a wide range of industries according to mesh sizes andWire Meshmaterials.

Exceptional Durability and Resistance

This Inconel Square Wire Mesh stands out for its remarkable tolerance to extreme temperatures, corrosive elements, and mechanical stress. Engineered with a coated, silver finish, it maintains stability and integrity, even in harsh chemical or industrial settings.

Versatile Industrial Applications

Suitable for filtration, separation, shielding, and reinforcement, the wire mesh adapts seamlessly to diverse industrial requirements. Its plain mesh style promotes uniform flow and effective containment for liquids, solids, or gases, making it a preferred choice in manufacturing and processing plants.

FAQs of Inconel Square Wire Mesh:

Q: How does the coated surface treatment enhance the Inconel Square Wire Mesh?

A: The coated surface provides improved resistance against oxidation, corrosion, and environmental wear, extending the meshs operational life and ensuring reliable performance in demanding settings.Q: What are the typical applications of Inconel Square Wire Mesh?

A: It is commonly utilized for filtration, separation, and reinforcement in industries such as petrochemical, aerospace, chemical processing, and energy due to its robustness and stability under extreme conditions.Q: When is Inconel Square Wire Mesh preferred over other materials?

A: Inconel Square Wire Mesh is chosen when operating conditions involve high temperatures, aggressive chemicals, or corrosive environments, where conventional materials may not deliver adequate longevity or safety.Q: Where is this wire mesh manufactured and exported from?

A: This Inconel wire mesh is manufactured and exported by established exporters, manufacturers, suppliers, and traders based in India, ensuring adherence to international standards and competitive delivery timelines.Q: What is the process for fabricating Inconel Square Wire Mesh?

A: Fabrication involves precision weaving of Inconel wires into a plain mesh style, followed by a specialized coating process that imparts extra durability and corrosion resistance to the finished product.Q: How is the mesh utilized in industrial settings?

A: Industries employ this mesh for critical functions such as filtration of liquids and gases, shielding components from heat or interference, and providing structural reinforcement in assemblies.Q: What advantages does Inconel offer compared to traditional wire mesh materials?

A: Inconel boasts superior strength, exceptional resistance to heat and corrosion, and longer service life, making it a prime choice for high-performance industrial applications where reliability is paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Square Wire Mesh Category

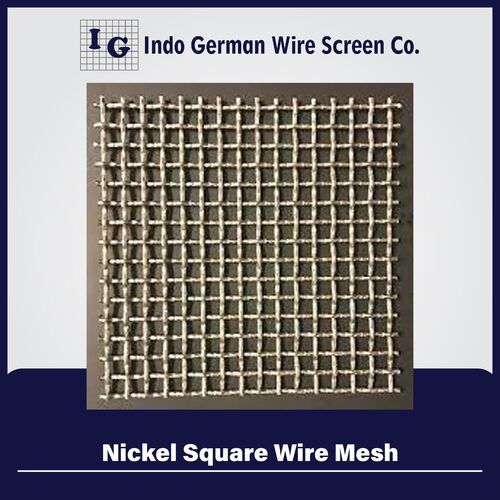

Nickel Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Nickel

Application : Other

Product Type : Wire Mesh

Mesh Style : Plain Mesh

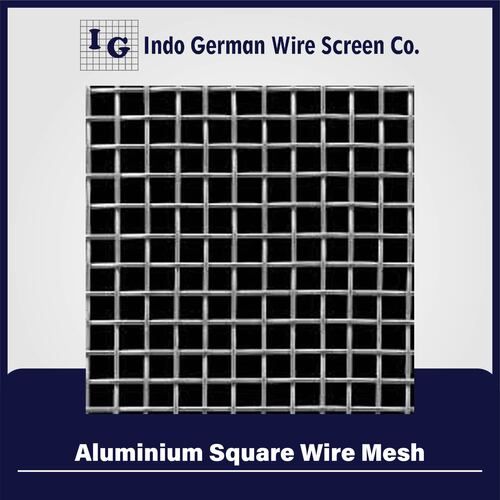

Aluminium Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Aluminum

Application : Other

Product Type : Wire Cloth

Mesh Style : Plain Mesh

Titanium Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Titanium

Application : Other

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Tungsten Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Tungsten

Application : Other

Product Type : Wire Mesh

Mesh Style : Plain Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry