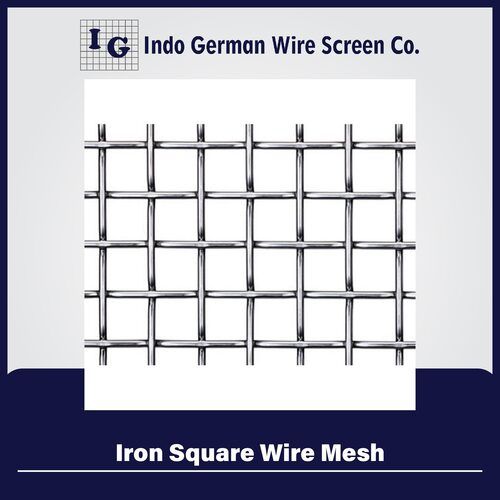

Iron Square Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Iron Square Wire Mesh Specification

- Hole Shape

- Rectangle Hole

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Material

- Iron

- Application

- Other

- Color

- Gray

Iron Square Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Iron Square Wire Mesh

Iron contains iron with no further treatment galvanizing required and has a natural colour of black.Iron Square Wire Mesh or Square Wire Nettingis a welded wire mesh panel specifically manufactured by welding thin and thick diameter wires to form a square mesh hole.Iron Square Wire Meshis in great demand and widely used for security purposes, sifting, machinery guard, sign panel, windows and hardware fittings, protective enclosure in cages, poultry farms, power plants, various factories, house fencing, zoos and many other areas.Iron Square Wire Meshis extensively used for sieving, particle separation, filtering, safety and equipment protection, window screen, food processing industries, infill panels, and many more uses and find applications in a wide range of industries according to mesh sizes andWire Meshmaterials.Durable Iron Wire Mesh

Our Iron Square Wire Mesh stands out for its exceptional strength and longevity, thanks to high-quality iron construction. The coated surface enhances resistance to corrosion and wear, making it suitable for demanding environments. With a rectangular hole shape, it offers optimal structure and aesthetic appeal, supporting a wide range of applications from fencing to filtration.

Versatile Applications

This iron mesh excels in multiple uses, including security barriers, construction reinforcements, window guards, and industrial screening. Its adaptable design and reliable performance ensure it meets the needs of both large-scale and custom projects. We supply in bulk and tailored sizes to match your specifications.

FAQs of Iron Square Wire Mesh:

Q: How is Iron Square Wire Mesh manufactured?

A: Iron Square Wire Mesh is produced by weaving or welding iron wires into a grid pattern with rectangular holes. The mesh receives a specialized coating after assembly to enhance durability and provide a uniform gray appearance.Q: What are the primary uses of Iron Square Wire Mesh?

A: Iron Square Wire Mesh is frequently used for fencing, construction reinforcement, security grilles, partitions, and ventilation panels due to its strength and flexibility. It also performs well in filtration and screening applications.Q: When is coated iron wire mesh preferred over other materials?

A: Coated iron wire mesh is ideal when extra protection against corrosion is needed. Its durable surface treatment makes it suitable for environments exposed to moisture, chemicals or harsh weather, ensuring longevity compared to untreated mesh.Q: Where can this mesh be installed?

A: Iron Square Wire Mesh is suitable for both indoor and outdoor installations. Common locations include building facades, industrial enclosures, warehouses, agricultural zones, and residential properties across India and international markets.Q: What is the coating process for the iron mesh?

A: The coating process involves applying a protective layer to the iron mesh, usually through galvanization or specialized painting, to increase resistance to rust and abrasion while maintaining a clean, gray finish.Q: How does using iron wire mesh benefit industrial projects?

A: Iron wire mesh provides reinforcing strength, reliable security, and effective partitioning in industrial settings. Its coated surface reduces maintenance costs and extends service life, supporting safer and more efficient operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Square Wire Mesh Category

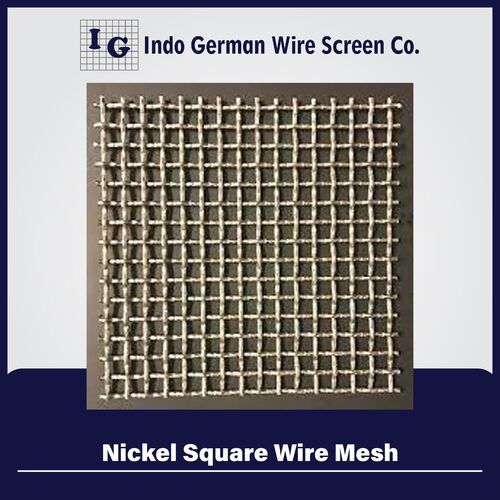

Nickel Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Mesh Type : Other

Surface Treatment : Coated

Color : Silver

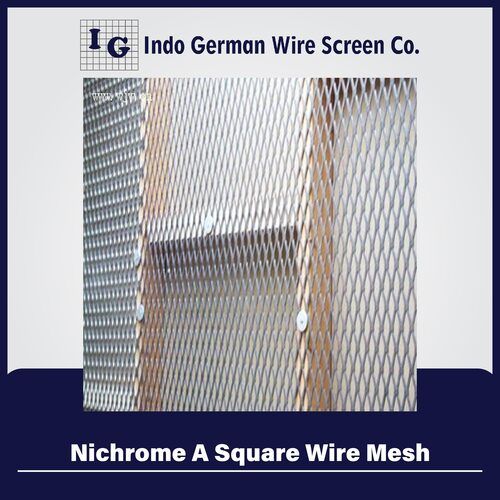

Nichrome A Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Woven Mesh

Mesh Type : Other , Nichrome Mesh Wire

Surface Treatment : Coated

Color : Silver

Tungsten Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Mesh Type : Other , Tungsten Wire Mesh

Surface Treatment : Coated

Color : Silver

Stainless Steel Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Mesh Type : Steel Wire Mesh

Surface Treatment : Coated

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry