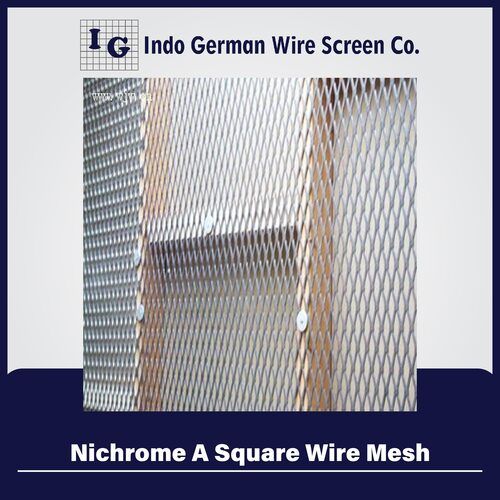

Nichrome A Square Wire Mesh

Price 50 INR/ Unit

Nichrome A Square Wire Mesh Specification

- Aperture

- 5 mm

- Wire Gauge

- 22 SWG

- Surface Treatment

- Coated

- Length

- 25 Meter Roll

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Nichrome Mesh Wire

- Mesh Style

- Woven Mesh

- Material

- Nichrome Alloy (NiCr A)

- Alloy

- Nickel-Chromium (80/20)

- Application

- Industrial Filtration, Heating Elements, Chemical Processing

- Dimensions

- 1 Meter Width x 25 Meter Length

- Wire Diameter

- 0.71 mm

- Weight

- Approx. 3.2 kg per 25 m roll

- Color

- Silver

Nichrome A Square Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nichrome A Square Wire Mesh

Nichrome is the alloy of nickel and chrome and, according to different chemical compositions, can be divided into Cr20Ni80, Cr15Ni60 and Cr20Ni35.Nichrome A Square Wire Mesh or Square Wire Nettingis a welded wire mesh panel specifically manufactured by welding thin and thick diameter wires to form a square mesh hole.Square wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.Nichrome A Square Wire Meshis easy to work with and is available in different hole sizes, thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range ofNichrome A Square Wire Meshat unmatched quality and market leading prices.

Engineered for Extreme Temperatures

This Nichrome A Square Wire Mesh is designed to function reliably in environments reaching up to 1200C. Its superior heat tolerance makes it a preferred choice for heating elements and processes requiring resistance to high thermal stress, ensuring durability and performance.

Outstanding Corrosion Resistance

Made from an 80/20 nickel-chromium alloy, this mesh is highly resistant to oxidation and corrosion. Its robust material and coated surface allow it to thrive in harsh chemical and filtration applications, providing longevity even in aggressive industrial environments.

Versatile Industrial Applications

With a 5 mm aperture and 5 mesh count, this woven wire mesh is perfect for industrial filtration, chemical processing, and as a heating element. Its square design and precision construction offer flexibility and reliability across a diverse range of processes.

FAQs of Nichrome A Square Wire Mesh:

Q: How is the Nichrome A Square Wire Mesh commonly used in industrial applications?

A: This mesh is widely utilized for industrial filtration, heating elements, and chemical processing due to its high temperature tolerance, corrosion resistance, and consistent aperture size.Q: What benefits does the 80/20 nickel-chromium alloy composition offer?

A: The 80/20 nickel-chromium composition gives the mesh outstanding resistance to corrosion, oxidation, and high temperatures, making it durable and reliable for prolonged industrial use.Q: When should I choose Nichrome mesh with a 5 mm aperture and 5 mesh count?

A: Opt for this configuration when you need efficient filtration or precise heat distribution in chemical, industrial, or heating element applications. The 5 mm aperture ensures effective flow while maintaining structural integrity.Q: What process is used for surface treatment of the mesh?

A: The Nichrome mesh undergoes a coating treatment that enhances its resistance to oxidation and environmental wear, extending its usable life in demanding settings.Q: Where is this Nichrome A wire mesh manufactured and supplied from?

A: This mesh is manufactured, exported, supplied, and traded by reputable companies in India, ensuring consistent quality and global distribution.Q: How do I calculate the electrical resistance for my application?

A: For a 0.71 mm diameter wire, the electrical resistance is 1.09 /m. Multiply this value by the length of wire used in your design to determine total resistance.Q: What are the main benefits of using Nichrome A Square Wire Mesh in heating elements?

A: The high melting point, stable resistance, and excellent corrosion resistance of Nichrome A mesh make it particularly suitable for durable and efficient heating elements in industrial equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Square Wire Mesh Category

Stainless Steel Welded Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Style : Plain Mesh

Mesh Type : Aluminum Wire Mesh

Hastelloy Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Style : Plain Mesh

Mesh Type : Other , Hastelloy Square Wire Mesh

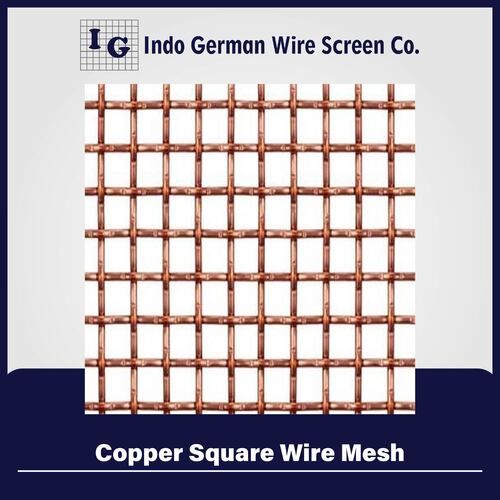

Copper Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Copper

Surface Treatment : Coated

Mesh Style : Plain Mesh

Mesh Type : Copper Wire Mesh

Mild Steel Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Style : Plain Mesh

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry