Inconel Woven Wire Mesh

Price 50 INR/ Unit

Inconel Woven Wire Mesh Specification

- Hole Shape

- Square

- Length

- Custom lengths or standard rolls up to 30 meters

- Wire Gauge

- 10-50 SWG

- Aperture

- 0.1mm to 50mm

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave / Twill Weave

- Mesh Style

- Woven Mesh

- Material

- Inconel (Nickel-Chromium Alloy)

- Alloy

- Inconel 600/601/625/718

- Application

- Other

- Dimensions

- Customized or standard sizes (typically 1m x 15m roll)

- Wire Diameter

- 0.025 mm to 5 mm

- Weight

- Variable, depending on specification

- Color

- Silver

- Open Area Percentage

- Varies by mesh, typically 30%-80%

- Operating Temperature

- Up to 1150°C

- Melting Point

- Approximately 1354°C - 1413°C

- Usage

- Filtration, chemical processing, aerospace, marine, and power generation industries

- Tensile Strength

- High

- Edge Type

- Cut Edge or Selvage Edge

- Corrosion Resistance

- Excellent, suitable for harsh chemical environments

Inconel Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Woven Wire Mesh

Exceptional Durability in Harsh Conditions

Engineered from Inconel alloys, this woven wire mesh retains its structural integrity and resists corrosion in the most challenging chemical and thermal environments. Its high melting point and tensile strength allow for reliable operation in filtration, separation, and shielding applications that demand utmost durability.

Customizable Specifications for Diverse Applications

With customizable dimensions, apertures, and weave styles, Inconel wire mesh can be precisely tailored to specific project requirements. Whether for chemical processing equipment, marine environments, or aerospace shielding, it delivers optimal filtration efficiency and mechanical performance.

FAQs of Inconel Woven Wire Mesh:

Q: How does Inconel woven wire mesh perform in high-temperature environments?

A: Inconel woven wire mesh exhibits superior performance at high temperatures, operating reliably up to 1150C. Its nickel-chromium alloy composition retains mechanical strength and resists oxidation and surface degradation, making it ideal for applications in power generation, aerospace, and chemical industries.Q: What benefits does Inconel mesh offer in corrosive or chemical environments?

A: Thanks to its exceptional resistance to acids, alkalis, and oxidizing agents, Inconel mesh is well-suited for harsh chemical settings. This durability reduces maintenance frequency, extends service life, and ensures safety in chemical processing and marine environments.Q: Where is Inconel wire mesh commonly used?

A: Inconel woven mesh finds applications in filtration, separation, shielding, and reinforcement within chemical processing plants, power generation facilities, marine vessels, and aerospace components. Its adaptability to custom sizes makes it suitable for various industrial sectors.Q: What are the customization options available for this mesh?

A: Customers can order Inconel wire mesh in standard or custom rolls up to 30 meters, specified lengths, widths, wire gauges (10-50 SWG), apertures (0.1 mm to 50 mm), opening percentage, edge type, and surface coatings. Both plain and twill weave styles are available to cater to unique filtration and mechanical requirements.Q: How is Inconel woven mesh installed or used in processes?

A: Installation depends on application and can involve framing, fabrication into filter units, or direct integration into equipment for strainers, screens, and barriers. Its flexibility in size and design facilitates easy adaptation into existing or new industrial systems.Q: Why choose Inconel mesh over other metallic meshes?

A: Inconel mesh offers superior corrosion and heat resistance compared to most other metal meshes, such as stainless steel or brass. Its longevity and reliability in extreme environments help lower total operational costs over time, making it a preferred choice for critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

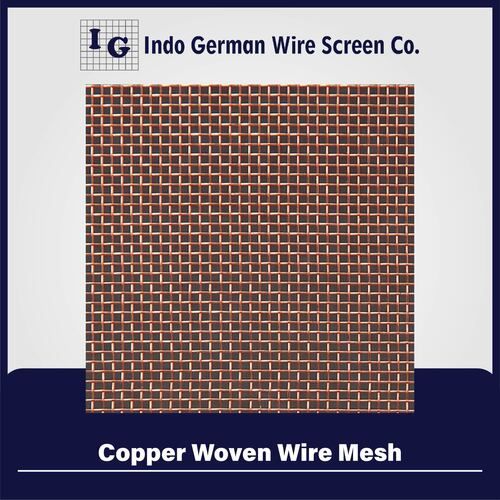

Copper Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Copper

Mesh Type : Copper Wire Mesh

Nickel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Battery Electrode, Chemical Processing, Laboratory, Aerospace, Electronics

Surface Treatment : Other, Bright Annealed

Color : Silver Grey

Mesh Type : Other , Woven

Tungsten Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Sieving, Electronics, Aerospace, Medical, Chemical processing

Surface Treatment : Other, Uncoated

Color : Metallic grey

Mesh Type : Other , Woven

Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Silver

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry