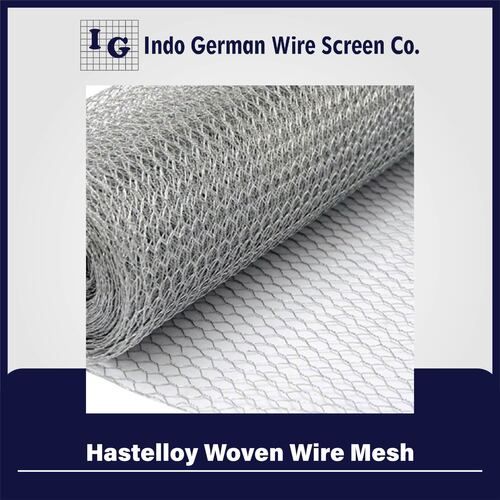

Hastelloy Woven Wire Mesh

Price 50 INR/ Unit

Hastelloy Woven Wire Mesh Specification

- Length

- Custom length available (typically 15-30 meters per roll)

- Wire Gauge

- Standard gauge available as per requirement

- Surface Treatment

- Coated

- Aperture

- 0.025 mm to 10 mm (as per specification)

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Fine Mesh / Crimped Mesh (optional)

- Mesh Style

- Woven Mesh

- Material

- Hastelloy

- Alloy

- Hastelloy C-276 / Hastelloy B / Hastelloy X (customizable)

- Application

- Other

- Dimensions

- Custom sizes available (width: 0.5m to 2m)

- Wire Diameter

- 0.02 mm to 2 mm (customizable)

- Weight

- Varies based on mesh size and wire diameter

- Color

- Silver

Hastelloy Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Hastelloy Woven Wire Mesh

Hastelloy is a corrosion resistant alloy and has a higher work hardening rate than the austenitic stainless steels which should be taken into consideration. Hastelloy has a smooth surface and has an excellent aesthetic appearance and will not easily fray or unravel, is stable and rigid. Hastelloy construction provides durable and strong packing that can withstand the harshest environments.The mesh itself will remain strong and stable with a high percentage of open area. Different patterns such as plain weave, twilled weave, and plain dutch weave are made on these types of weaving looms.Hastelloy Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Hastelloy Woven Wire mesh is ideal for both industrial & architectural applications.

Superior Corrosion Resistance

Hastelloy Woven Wire Mesh stands out for its excellent resistance to both acids and chloride-rich environments. Its resilient alloy composition makes it suitable for long-term use in aggressive chemical processes, marine applications, and oil & gas industries where other materials may degrade rapidly.

Versatile Weave and Custom Dimensions

Choose between plain and twilled weave options, tailored to meet your specific filtration or separation requirements. With customizable mesh apertures and wire diameters, the mesh can be manufactured in a range of sizes and styles, such as fine or crimped mesh, accommodating diverse industrial demands.

Reliability Under Extreme Conditions

This mesh is designed to operate efficiently in high-temperature environments (up to 1093C/2000F) with a high melting point (13251370C). Engineered for long service life, it withstands severe environments while maintaining structural integrity and performance.

FAQs of Hastelloy Woven Wire Mesh:

Q: How is Hastelloy Woven Wire Mesh typically used in industrial applications?

A: This mesh is widely used for filtration, separation, and screening in industries such as aerospace, chemical processing, marine, and oil & gas. Its resistance to corrosion and high temperatures makes it invaluable for demanding operational conditions.Q: What are the available weaving types for Hastelloy mesh, and how do they differ?

A: The mesh is offered in both plain weave and twilled weave options. Plain weave provides a straightforward, stable structure ideal for most filtration tasks, while twilled weave offers increased flexibility and strength for applications requiring finer mesh or greater durability.Q: When should I choose Hastelloy mesh over other metal meshes?

A: Select Hastelloy mesh when operating in environments involving aggressive chemicals, acids, or high temperatures, where standard stainless steel or other alloys might fail. Its long-lasting performance ensures reduced maintenance and replacement costs in harsh settings.Q: Where can Hastelloy Woven Wire Mesh be used most effectively?

A: It is most effective in environments prone to severe corrosion and extreme temperatures, such as chemical reactors, marine environments, high-pressure filtration units, and gas turbines.Q: What is the process for customizing wire diameter and mesh dimensions?

A: Customization is available on request. You may specify aperture size (0.025 mm to 10 mm), wire diameter (0.02 mm to 2 mm), roll width (0.5m to 2m), and length (typically 15-30 meters per roll) according to your application needs, ensuring precise fit and performance.Q: How does the mesh benefit operations in high-corrosive and high-temperature environments?

A: Owing to its exceptional resistance to acids, chlorides, and elevated temperatures up to 1093C, the mesh minimizes downtime, enhances safety, and ensures consistent filtration or separation efficiency over a long service life, even under severe conditions.Q: What are the packing and delivery standards for Hastelloy Woven Wire Mesh?

A: The mesh is securely roll-packed with protective wrapping to prevent damage during transit and storage. Products conform to relevant ASTM/ASME specifications and can be shipped globally from India by exporters, manufacturers, suppliers, and traders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

Titanium Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other, Filtration, chemical processing, marine, aerospace, medical, battery, paper and pulp, seawater desalination

Mesh Style : Woven Mesh

Surface Treatment : Coated

Inconel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Style : Woven Mesh

Surface Treatment : Coated

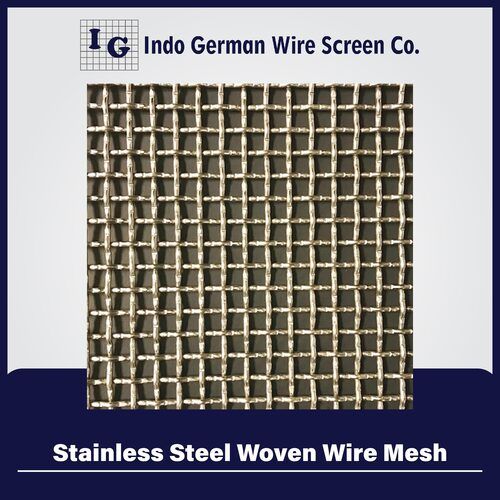

Stainless Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Woven Wire Mesh

Application : Other, Filtration, Sieving, Security, Industrial, Architectural

Mesh Style : Other , Plain weave

Surface Treatment : Mill Finish

Tungsten Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Woven Wire Mesh

Application : Other, Filtration, Sieving, Electronics, Aerospace, Medical, Chemical processing

Mesh Style : Other , Plain weave, Twilled weave

Surface Treatment : Other, Uncoated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry