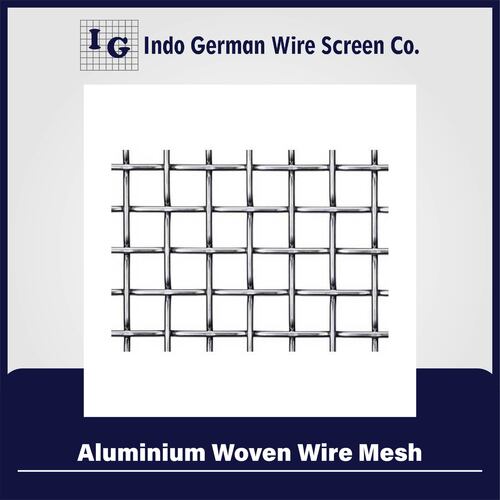

Aluminium Woven Wire Mesh

Price 50 INR/ Unit

Aluminium Woven Wire Mesh Specification

- Wire Gauge

- 10 to 30 SWG

- Aperture

- 0.5 mm - 10 mm

- Surface Treatment

- Mill finish, Anodized

- Length

- 15 m, 30 m, or custom

- Hole Shape

- Square

- Product Type

- Woven Wire Mesh

- Mesh Type

- Plain Weave, Twill Weave

- Mesh Style

- Woven

- Material

- Aluminium

- Alloy

- Aluminium 1100/1200 or as specified

- Application

- Screening, Filtration, Insect screens, Partitioning, Fencing

- Dimensions

- Width: 0.5 m - 2.0 m; Roll or cut-to-size

- Wire Diameter

- 0.3 mm - 2.5 mm

- Weight

- Lightweight, varies with specification

- Color

- Silver

About Aluminium Woven Wire Mesh

Aluminium is the most popular non-ferrous metal and aluminium alloys are generally used in the wire mesh industry. Aluminium alloys contain other elements like copper, magnesium, manganese, or silicon with aluminium. Aluminium is a first choice metal for a wide range of industries including marine, automotive, aerospace, and electrical conductivity applications. The mesh itself will remain strong and stable with a high percentage of open area. Different patterns such as plain weave, twilled weave, and plain dutch weave are made on these types of weaving looms.Aluminium Woven Wire Meshes are exceptionally multipurpose and adaptable and easy to install, and are used in numerous applications. Heavier Aluminium Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Aluminium Woven Wire mesh is ideal for both industrial & architectural applications.

Durable and Lightweight Construction

Our aluminium woven wire mesh features a balance of strength (tensile strength 90120 MPa) and lightweight design, making it easy to handle and install. The use of premium aluminium alloys provides outstanding resistance to corrosion and high temperatures, extending mesh longevity in challenging environments.

Versatile Packing and Customization Options

Available in roll lengths of 15 m, 30 m, or tailored to your specifications, the mesh is securely packed in waterproof wrapping for safe transport and storage. Edges can be finished plain or selvedge, and dimensions, wire diameter, and mesh aperture can be customized to precisely fit your project needs.

FAQs of Aluminium Woven Wire Mesh:

Q: How is aluminium woven wire mesh typically used?

A: Aluminium woven wire mesh is utilized for screening, filtration, insect screening, partitioning, and fencing due to its lightweight yet durable properties. Its corrosion resistance and customizable options make it suitable for both indoor and outdoor use.Q: What are the benefits of using plain weave aluminium mesh?

A: Plain weave provides a stable, flexible, and reliable structure that balances open area with strength. This makes it ideal for applications requiring good airflow, visibility, and mechanical durability, such as ventilation panels and insect screens.Q: What is the process for ordering custom sizes and specifications?

A: You can specify your desired width, length, aperture, wire gauge, and edge finish when placing an order. Panels or rolls are then manufactured to your precise needs, adhering to ASTM B211 or JIS H4000 standards where required.Q: Where can aluminium woven wire mesh be installed?

A: This mesh can be installed in industrial, residential, and commercial settingsanywhere that requires filtration, screening, or protective enclosures. Its lightweight nature allows for easy mounting on various frameworks and structural supports.Q: When should a customer choose mill finish versus anodized surface treatment?

A: Mill finish offers natural aluminium appearance and adequate protection for most environments, while anodized finishes provide enhanced corrosion and abrasion resistance, recommended for more aggressive or decorative applications.Q: How is the mesh packaged and delivered to ensure quality?

A: The mesh is shipped as rolls or custom-cut panels, each securely wrapped in waterproof material to minimize the risk of damage during transit. This guarantees the material arrives in optimal condition, ready for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

Copper Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Copper

Product Type : Wire Mesh

Application : Other

Mesh Style : Other , Woven

Inconel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Wire Mesh

Application : Other

Mesh Style : Woven Mesh

Stainless Steel Welded Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Other, Welded Woven Wire Mesh

Application : Other, Fencing, Filtration, Construction, Industrial & Agricultural Uses

Mesh Style : Other , Welded, Woven

Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Wire Mesh

Application : Other

Mesh Style : Woven Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry