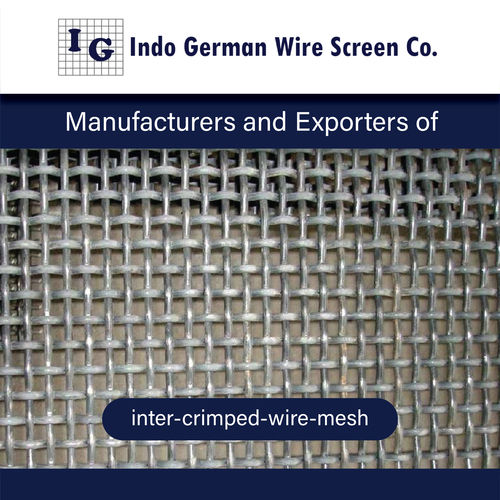

Inter Crimped Wire Mesh

Price 1000-100000.00 INR/ Foot

Inter Crimped Wire Mesh Specification

- Surface Treatment

- Galvanized

- Length

- Up to 30 meters

- Wire Gauge

- 14 - 20 SWG

- Hole Shape

- Square

- Aperture

- 6 mm 50 mm

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Crimped Wire Mesh

- Material

- Galvanised Steel

- Alloy

- Low Carbon Steel

- Application

- Fencing, Filtration, Sieving, Construction, Industrial Uses

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.8 mm 2.5 mm

- Weight

- Varies as per size and specification

- Color

- Silver

- Finish

- Bright & Smooth

- Thickness

- As per requirement

- Tensile Strength

- 350 - 550 MPa

- Usage

- Construction, Mining, Agriculture, Security

- Corrosion Resistance

- Yes

- Opening Size

- Customizable

- Edge Type

- Plain or Welded Edges

- Packing Type

- Rolls or sheets

Inter Crimped Wire Mesh Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Cheque, Letter of Credit (L/C), Cash in Advance (CID)

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Inter Crimped Wire Mesh

Inter crimped Wire mesh is made of all kind of alloy and metals and also very popular

Woven wire mesh with an extra crimp in both warp and fill wire is known as inter crimped wire mesh. Both the warp and Shute/ weft wires are crimped with extra crimps or corrugations between the points of intersection. This technique is usually required when weaving large openings with fine wires.

Product details

|

Color |

Silver |

|

Crimp Style |

Double Crimp |

|

Hole Shape |

Square |

|

Material |

Galvanised Steel |

|

Mesh Number Size |

1-10 |

|

Opening Size |

<1/4 Inch |

|

Surface Treatment |

Hot Dipped Galvanized |

|

Thickness |

<12 Gauge (2.68 mm) |

|

Usage/Application |

Rubber Industry,Food Industry,Aquaculture Industry,Mining Industry,Medicinal purpose |

|

Weave Type |

Plain |

Premium Quality Material and Customization

Manufactured from galvanized low carbon steel, Inter Crimped Wire Mesh ensures enhanced durability and corrosion resistance. Every mesh can be tailored to specific size, wire gauge, opening, and finish requirements, making it adaptable for a wide spectrum of applications. Whether for construction, mining, or fencing, our products are supplied as per individual project demands, promising longevity and reliable performance.

Versatile Applications in Multiple Industries

This wire meshs strength and corrosion resistance suit it for diverse environmentsbe it sieving in agriculture, filtration in industry, or security fencing. The customizable aperture (6 mm 50 mm) and malleable sheet lengths mean our mesh easily fits unique operational needs. Its bright, smooth finish further prevents material buildup and eases maintenance, making it a preferred choice for professionals.

FAQs of Inter Crimped Wire Mesh:

Q: How is Inter Crimped Wire Mesh commonly used in industries?

A: Inter Crimped Wire Mesh is widely used for fencing, filtration, sieving, and as safety barriers in construction, industrial, agricultural, mining, and security applications. Its strength and customizable dimensions make it suitable for both protective and functional uses.Q: What customization options are available for this wire mesh?

A: Clients can specify mesh opening sizes (6 mm50 mm), wire diameters (0.8 mm2.5 mm), length (up to 30 meters), wire gauge (1420 SWG), edge type (plain or welded), hole shape, finish, and overall dimensions to meet project-specific requirements.Q: What process is followed for manufacturing Inter Crimped Wire Mesh?

A: The mesh is manufactured from galvanized steel wires that are crimped and interwoven at precise intervals. This process ensures uniformity, a stable structure, and a bright, smooth surface. Final meshes are checked for tensile strength, surface finish, and corrosion resistance.Q: Where can this wire mesh be supplied or installed?

A: As a leading exporter, manufacturer, supplier, and trader based in India, Inter Crimped Wire Mesh can be dispatched across India and internationally. It can be installed in construction sites, agricultural fields, industrial facilities, mining operations, and perimeter security systems.Q: What are the main benefits of choosing galvanized Inter Crimped Wire Mesh?

A: The primary advantages include exceptional corrosion resistance, strength, and adaptability for heavy-duty applications. Its bright, smooth finish reduces the risk of material cling and simplifies cleaning, while the ability to custom-order ensures a tailored solution every time.Q: When should one opt for plain edges versus welded edges?

A: Plain edges are suitable for many standard fencing and screening uses, while welded edges offer added strength and stability, particularly for heavy-duty or high-security purposes. The choice depends on the required durability and the operational environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crimped Wire Mesh Category

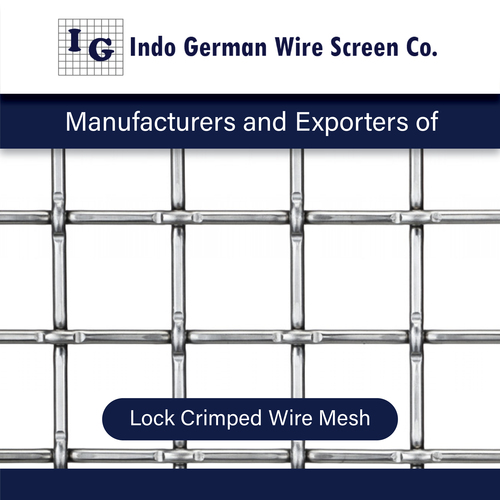

Lock Crimped Wire Mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Color : Silver

Material : Stainless Steel

Mesh Type : Iron Wire Mesh

Mesh Style : Crimped Wire Mesh

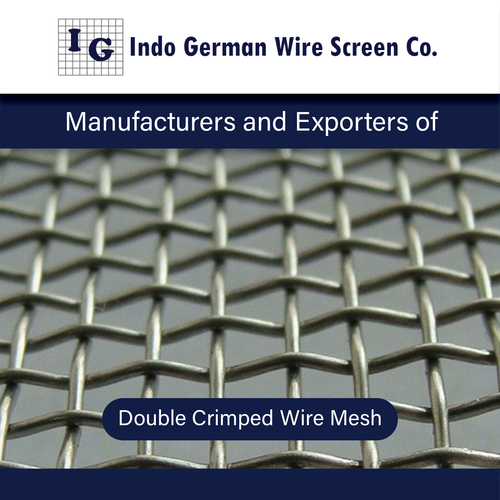

Double Crimped Wire Mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Mesh Style : Crimped Wire Mesh

Clamp Crimped Wire Mesh

Color : Silver

Material : Steel

Mesh Type : Steel Wire Mesh

Mesh Style : Crimped Wire Mesh

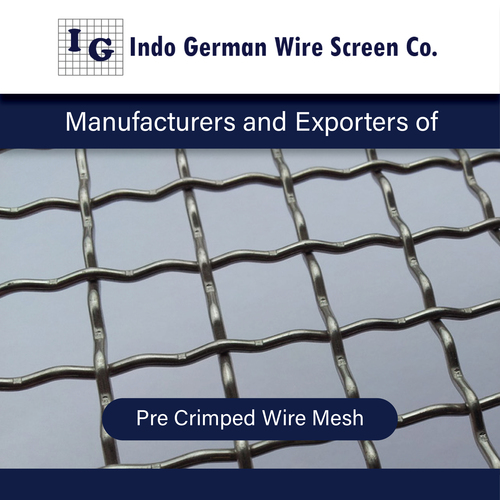

Pre Crimped Wire Mesh

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Mesh Style : Crimped Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry