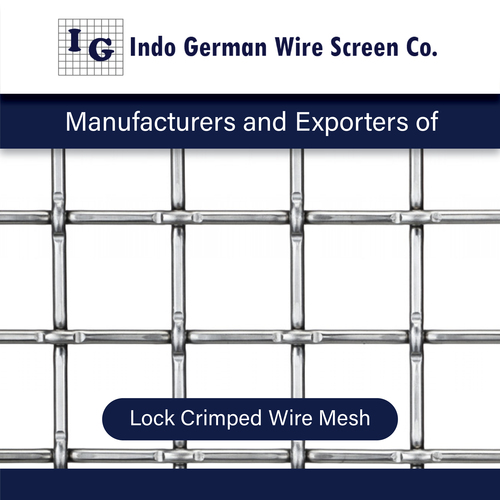

Lock Crimped Wire Mesh

Price 1000-100000.00 INR/ Foot

Lock Crimped Wire Mesh Specification

- Wire Gauge

- 2mm to 12mm

- Surface Treatment

- Galvanized / Polished

- Length

- Custom Lengths Available

- Hole Shape

- Rectangular / Square

- Aperture

- 6mm to 100mm

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Mesh Style

- Crimped Wire Mesh

- Material

- Stainless Steel

- Alloy

- Stainless Steel 304 / 316

- Application

- Fencing, Mining, Sieve, Security, Construction

- Dimensions

- Custom Sizes

- Wire Diameter

- 2mm to 12mm

- Weight

- Varies by Size

- Color

- Silver

- Tensile Strength

- High Tensile

- Thickness Tolerance

- ±0.1mm

- Corrosion Resistance

- Excellent

- Opening Type

- Locked

- Edge Type

- Cut Edges / Bent Edges

- Temperature Resistance

- Up to 800°C

- Packing Type

- Rolls or Sheets

- Weaving Technique

- Lock Crimp

- Usage Environment

- Indoor & Outdoor

Lock Crimped Wire Mesh Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Lock Crimped Wire Mesh

Applications of Crimped Wire Mesh

- For Mining industry

- For construction industry

- For petrochemical industry

- For Cement industry

- For food processing industry

- Heavy duty scalping and sizing of rocks, aggregates, limestone and etc

- For Filtering and separating

- For Pharmaceuticals Industry

- For Chemical industries

- For Rubber industries For automobile industries,

Product details

|

Country of Origin |

Made in India |

|

Material |

SS304 |

|

Brand |

Indo German |

|

Material Grade |

304,316 and others |

|

I Deal In |

New Only |

|

Type |

Lock Crimped Wire Mesh |

|

Usage/Application |

Industrial |

Engineered for Strength and Versatility

Lock Crimped Wire Mesh is designed for high-performance environments where durability, strength, and precision matter. The secure lock crimp weaving technique provides uniform openings and exceptional structural integrity. Its adaptability to varied applicationsfrom construction to miningunderscores its reputation for reliability, whether used indoors or outdoors.

High-Quality Materials and Customization

Made from top-grade stainless steel (304 or 316) and iron wire, the mesh offers both longevity and resilience. Customers can choose from silver finishes, wire diameters of 2mm to 12mm, and apertures ranging from 6mm to 100mm. Custom sizes and lengths are readily available, ensuring a precise fit for any project or installation.

FAQs of Lock Crimped Wire Mesh:

Q: What applications are Lock Crimped Wire Mesh commonly used for?

A: Lock Crimped Wire Mesh is widely used in fencing, mining, security barriers, construction reinforcement, and for sieves or filters. Its locked opening type and robust construction ensure stable performance in both indoor and outdoor environments.Q: How does the lock crimp weaving technique benefit the meshs performance?

A: The lock crimp weaving technique tightly secures the wires at their intersections, maintaining consistent opening sizes and enhancing mesh stability. This process increases the meshs load-bearing capacity and durability under stress.Q: What materials and finishes are available for this mesh, and how do they impact longevity?

A: Our wire mesh is available in stainless steel (304/316) and iron wire, with surface treatments like galvanized or polished finishes. These materials and treatments provide excellent corrosion resistance, extending the lifespan even under harsh environmental or chemical exposure.Q: Can custom dimensions and specifications be ordered for specific projects?

A: Yes, Lock Crimped Wire Mesh can be manufactured in custom sizes, wire diameters (2mm to 12mm), and apertures (6mm to 100mm) according to project requirements. Both rolls and sheets with choice of edge type (cut or bent) are available.Q: Where is the mesh best installed, and what environment can it withstand?

A: This mesh is suitable for both indoor and outdoor installations due to its high corrosion resistance and temperature tolerance (up to 800C). It is ideal for areas requiring strength and exposure to varying weather or industrial conditions.Q: How is the mesh typically packaged and delivered?

A: Lock Crimped Wire Mesh is supplied in either rolls or sheets, depending on customer preference and application needs. Protective packing ensures the product arrives in excellent condition, ready for immediate installation or fabrication.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crimped Wire Mesh Category

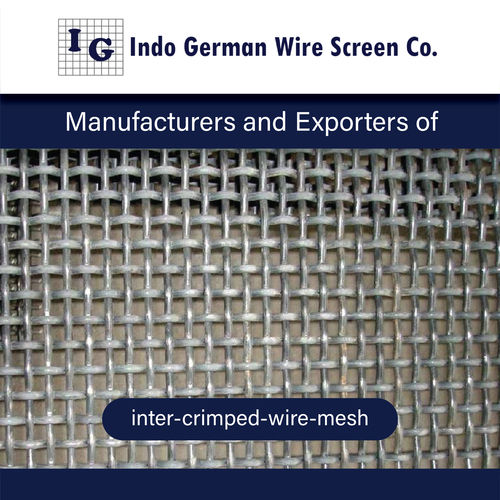

Inter Crimped Wire Mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Other, Galvanised Steel

Mesh Style : Crimped Wire Mesh

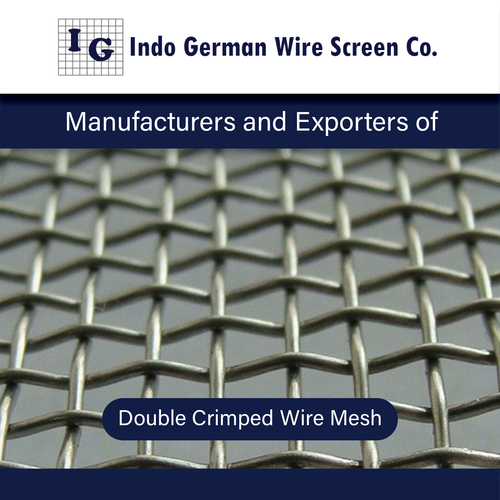

Double Crimped Wire Mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Stainless Steel

Mesh Style : Crimped Wire Mesh

Clamp Crimped Wire Mesh

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Steel

Mesh Style : Crimped Wire Mesh

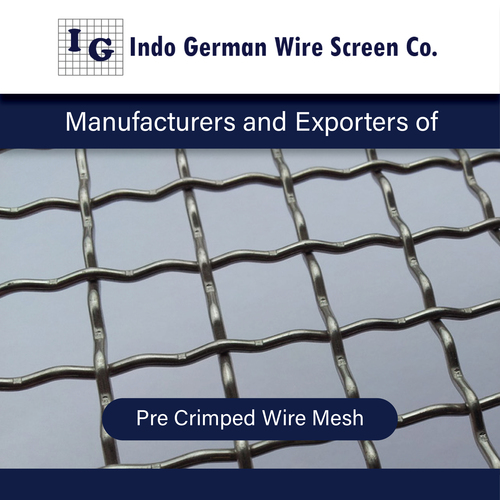

Pre Crimped Wire Mesh

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Stainless Steel

Mesh Style : Crimped Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry