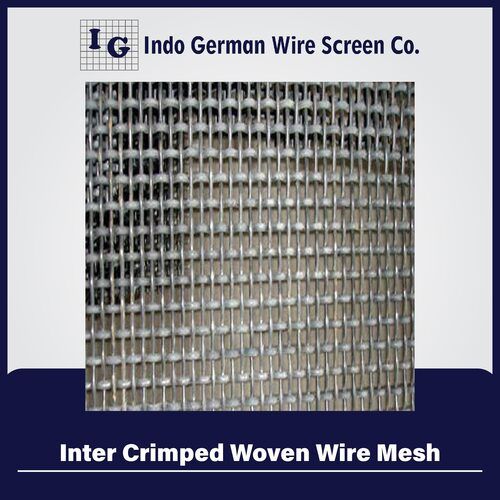

Inter Crimped Woven Wire Mesh

Price 50 INR/ Unit

Inter Crimped Woven Wire Mesh Specification

- Length

- As per requirement (commonly 25m rolls)

- Hole Shape

- Square or Rectangular

- Aperture

- 2 mm to 25 mm

- Wire Gauge

- 8 Gauge to 20 Gauge

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Inter Crimped

- Mesh Style

- Crimped Wire Mesh

- Material

- Metal Alloys

- Alloy

- Stainless Steel, Mild Steel, Galvanized Steel

- Application

- Other

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.5 mm to 2.5 mm

- Weight

- Variable (depends on mesh size and wire diameter)

- Color

- Silver

Inter Crimped Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inter Crimped Woven Wire Mesh

Inter Crimped Woven Wire Meshis technically a wire mesh panel accurately manufactured by woven to size in the same technique cloth is woven, manufactured on a loom.Inter Crimped Woven Wire Meshis made of all kinds of alloy and metals and also a very popular woven wire mesh with an extra crimp in both warp and fill wire is known as Inter Crimped Woven Wire Mesh.The mesh itself will remain strong and stable with a high percentage of open area.We offer an exclusive range ofInter Crimped Woven Wire Meshat unmatched quality and market leading prices.

Excellent Durability and Resistance

Crafted from premium metal alloys, Inter Crimped Woven Wire Mesh offers exceptional corrosion and temperature resistance. The option for stainless steel or galvanized finishes ensures longevity, even in harsh environments, making it ideal for industrial and outdoor uses.

Precision Engineering and Customization

With a customizable open area, aperture, wire diameter, and overall dimension, this mesh is meticulously engineered for accuracy. Customers can choose mesh styles, colors, and dimensions that meet their specific functional or aesthetic requirements.

Versatile Applications Across Industries

This wire mesh is suitable for screens, sieving, fencing, grills, and filtration. Its high tensile strength and robust construction make it a preferred solution for construction, mining, agriculture, and architectural projects.

FAQs of Inter Crimped Woven Wire Mesh:

Q: How is Inter Crimped Woven Wire Mesh manufactured?

A: The mesh is produced by interweaving metal wires that are crimped at precise intervals, which enhances structural integrity. You can choose from wire gauges between 8 to 20 and apertures ranging from 2 mm to 25 mm for tailored performance.Q: What benefits does the smooth and uniform finish offer?

A: A smooth and uniform finish improves aesthetic appeal and reduces the risk of snagging or injury during handling and installation. This finishing process also helps resist corrosion and facilitates easy maintenance.Q: Where can Inter Crimped Woven Wire Mesh be applied?

A: Common applications include industrial screening, filtration, fencing, grill work, protective partitions, and sieving for mining, construction, and food processing industries.Q: What are the options for mesh dimensions and packaging?

A: Customers may specify custom lengths, widths, and mesh sizes. Standard packaging is offered in rolls (commonly 25m) or sheets, securely packed for safe export and installation.Q: How does the mesh perform in high-temperature or corrosive environments?

A: Withstanding temperatures up to 600C (material dependent) and offering high corrosion resistance (especially with stainless steel or galvanized variants), the mesh is robust in demanding settings.Q: When should one choose cut edge vs. selvedge edge types?

A: Cut edge is suitable for general use, offering cost savings, while selvedge edge provides additional security against unraveling and is preferred where stability or repeated handling is essential.Q: What is the process for ordering customized Inter Crimped Woven Wire Mesh from India?

A: You can contact the manufacturer, supplier, or exporter in India with your project specificationssuch as required mesh type, dimensions, wire gauge, and finishing. The order will be produced as per your needs and exported with standard packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Five Shed Twill Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Hole Shape : Other , Rectangular

Mesh Style : Woven Mesh

Color : Silver

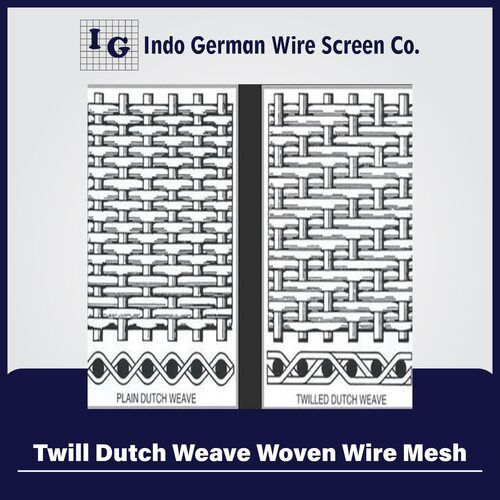

Twill Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Sifting, Sieving

Hole Shape : Other , Rectangular

Mesh Style : Woven Mesh

Color : Silver

Reverse Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Sieving, Extruder screens, Chemical and Food industry

Hole Shape : Other , Slotted

Mesh Style : Woven Mesh

Color : Silver / Metallic

Lock Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Hole Shape : Square Hole

Mesh Style : Crimped Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry