Pre Crimped Woven Wire Mesh

Price 50 INR/ Unit

Pre Crimped Woven Wire Mesh Specification

- Surface Treatment

- Coated

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Style

- Crimped Wire Mesh

- Material

- Metal Alloys

- Application

- Other

- Color

- Silver

Pre Crimped Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Pre Crimped Woven Wire Mesh

Pre Crimped Woven Wire Meshis technically wire mesh panel accurately manufactured by woven to size in the same technique cloth is woven manufactured on a loom.Pre Crimped Woven Wire Meshis intermediate crimped wire pre-crimped by the rotary dies. The pre-crimped wire can assure the spacing of the wires. When the wires are woven together, the structure can ensure the wires will lock firmly together at the intersections.Crimped mesh is made in the opening forms of square mesh or rectangular mesh. Rectangular opening crimped mesh refers normally to heavy type crimped mesh for mining, coal plant or pig breeding which require big loading capacity.Pre Crimped Woven Wire Meshis ideal for both industrial & architectural applications.This is used mainly with lighter wires to ensure tension in a light screen, and many more.

Superior Surface Protection with Coating

Our pre crimped woven wire mesh is treated with a high-quality coating, enhancing its resilience against rust and environmental wear. The coated surface not only prolongs the meshs lifespan but also maintains its aesthetic appeal and structural integrity, even in challenging industrial environments.

Durable Metal Alloys & Precision Engineering

Manufactured from selected metal alloys, this crimped wire mesh boasts strength and longevity. The square hole design ensures efficient screening or separation, making it suitable for applications demanding accuracy, such as filtration, fencing, and sieving operations.

FAQs of Pre Crimped Woven Wire Mesh:

Q: How is the pre crimped woven wire mesh manufactured?

A: The mesh is produced by weaving pre-crimped metal alloy wires together. The crimping process ensures that the wires lock tightly, leading to a uniform square hole pattern and enhanced mesh rigidity.Q: What surface treatment is applied to the wire mesh, and what are its benefits?

A: A specialized coating is applied to the mesh, providing excellent protection against corrosion, increasing the meshs durability, and ensuring longevity in harsh environments.Q: When should I choose pre crimped woven wire mesh for my application?

A: Pre crimped woven wire mesh is ideal when you require a robust and stable mesh structure for heavy-duty applications such as mining, construction, filtration, or fencing. Its durability makes it suitable for demanding operational conditions.Q: Where can this crimped wire mesh be used effectively?

A: It is widely used in industries including mining, architecture, chemical processing, filtration, fencing, and as protective barriers, thanks to its strength and precision square apertures.Q: What is the primary process involved in making the mesh crimped and durable?

A: The wires are first crimped to create firmness and then woven together, forming a mesh with square holes. This crimping procedure ensures dimensional consistency and prevents shifting of wires during use.Q: How does the silver color and coated finish benefit the mesh?

A: The silver color is not just visually appealing; combined with the coated finish, it helps minimize oxidation and surface damage, making the mesh suitable for indoor and outdoor environments.Q: What are the main benefits of sourcing crimped wire mesh from an Indian exporter and manufacturer?

A: By choosing an established exporter and manufacturer in India, you benefit from quality assurance, competitive pricing, customized sizes, and reliable global supply capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Five Shed Twill Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Hole Shape : Other , Rectangular

Surface Treatment : Coated

Mesh Style : Woven Mesh

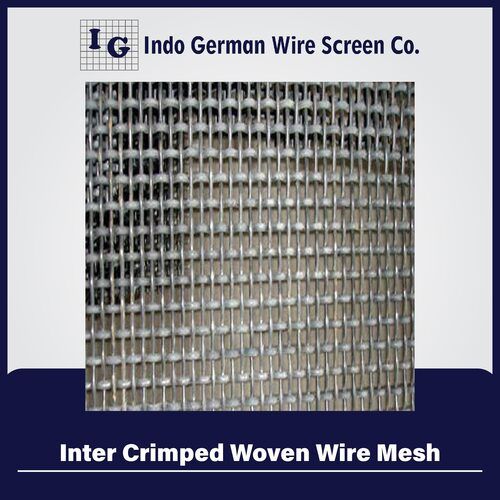

Inter Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Hole Shape : Other , Square or Rectangular

Surface Treatment : Coated

Mesh Style : Crimped Wire Mesh

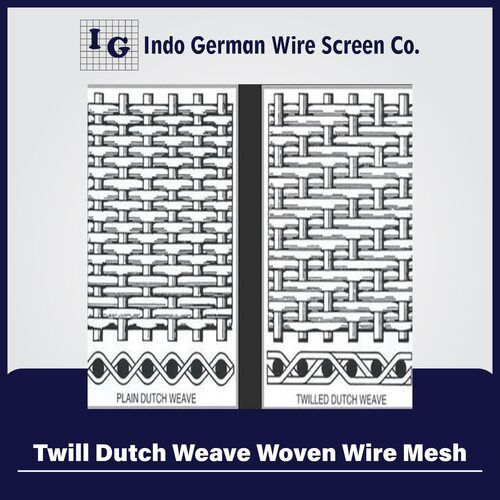

Twill Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Hole Shape : Other , Rectangular

Surface Treatment : Polished

Mesh Style : Woven Mesh

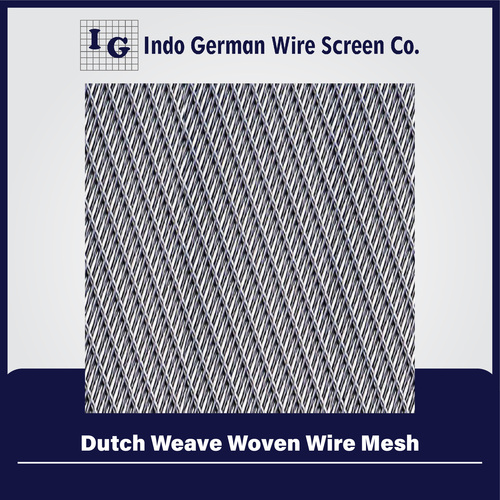

Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel, Brass, Copper

Hole Shape : Other , Rectangular

Surface Treatment : Other, Galvanized / Plain / Stainless Steel Finish

Mesh Style : Other , Dutch Weave

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry