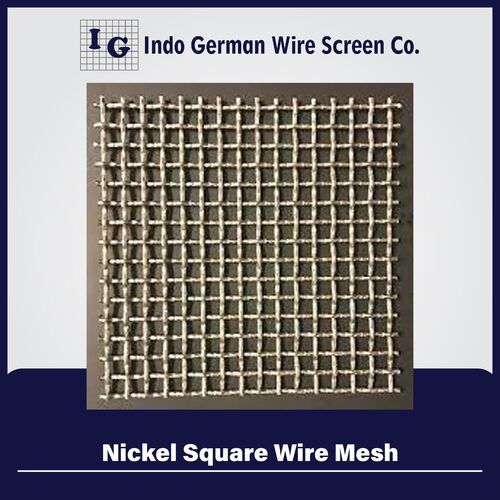

Nickel Square Wire Mesh

Price 50 INR/ Unit

Nickel Square Wire Mesh Specification

- Hole Shape

- Square

- Wire Gauge

- 30 Gauge

- Aperture

- Customized

- Length

- Customized

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Other

- Mesh Style

- Plain Mesh

- Material

- Nickel

- Alloy

- Nickel 200/201

- Application

- Other

- Dimensions

- Customized

- Wire Diameter

- 0.25 mm

- Weight

- Varies as per dimensions

- Color

- Silver

Nickel Square Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Square Wire Mesh

Nickel is a silvery-white hard metal whose strength ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids gas etc.Square wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.Nickel Square Wire Meshis easy to work with and is available in different hole sizes, and thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range ofNickel Square Wire Meshat unmatched quality and market leading prices.

Superior Temperature and Corrosion Resistance

With its ability to withstand temperatures up to 800C and excellent resistance to corrosive environments, Nickel Square Wire Mesh is ideal for demanding industrial sectors such as chemical processing and filtration. The high-purity nickel construction maintains integrity under severe operating conditions, ensuring longevity and reliability in every application.

Customizable Solutions for Diverse Applications

Nickel Square Wire Mesh is available in several customized dimensions, wire gauges, and opening sizes to suit specific project requirements. Whether your need is for precise apertures or bespoke sizes, the mesh is prepared as rolls or sheets, allowing flexible integration into electronics assembly, battery production, or advanced filtration systems.

FAQs of Nickel Square Wire Mesh:

Q: How is Nickel Square Wire Mesh manufactured to ensure optimal performance?

A: Nickel Square Wire Mesh is produced using high-purity Nickel 200/201 (99.6%), employing a plain weave technique. This process creates uniform square apertures and consistent wire spacing, with additional surface coating to enhance durability. Each mesh can be customized in dimension, wire gauge, and aperture to match specific usage requirements.Q: What are the benefits of choosing Nickel Square Wire Mesh for filtration and chemical processing?

A: Due to its excellent corrosion resistance and high temperature tolerance (up to 800C), Nickel Square Wire Mesh is highly advantageous for filtration and chemical processing. It maintains structural integrity when exposed to harsh chemicals or extreme heat, resulting in longer service life and reduced maintenance costs.Q: When should I use Nickel Square Wire Mesh in electronics and batteries?

A: Nickel Square Wire Mesh is particularly effective when high conductivity, corrosion resistance, and thermal stability are required in electronic components or battery systems. Its stable mesh structure allows for precise control of current flow, making it suitable for shielding, electrode fabrication, and various electronic assemblies.Q: Where can customized Nickel Wire Mesh be applied in industrial operations?

A: Customized Nickel Wire Mesh finds utility in a variety of industrial environments, including electronics manufacturing, battery assembly, chemical filtration systems, and specialized equipment for high-temperature processes. Its adaptability ensures seamless integration into existing operations, whether in sheet or roll form.Q: What options are available for packing Nickel Square Wire Mesh for shipment?

A: Nickel Square Wire Mesh can be packed as rolls or sheets, depending on customer specifications and intended use. Each package is carefully prepared to preserve mesh integrity during transit, ensuring that the product arrives in optimal condition for immediate deployment.Q: How does the purity and alloy composition affect mesh performance?

A: The high purity (99.6%) and use of Nickel 200/201 alloy provide superior resistance to oxidation, corrosion, and extreme temperatures. This combination ensures reliable performance and enhanced longevity, especially in chemical and electronic applications where material integrity is crucial.Q: What customization options are available for aperture and wire dimensions?

A: Aperture size, wire diameter (0.25 mm, 30 gauge), mesh width (up to 1.5 meters), roll length (15 meters), and total dimensions can all be customized. This flexibility supports precise adaptation to unique project requirements, maximizing efficiency and suitability for specialized tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Square Wire Mesh Category

Stainless Steel Welded Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Aluminum Wire Mesh

Material : Aluminum

Stainless Steel Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Steel Wire Mesh

Material : Stainless Steel

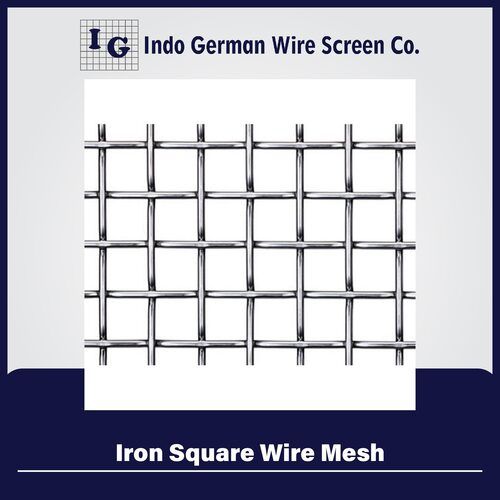

Iron Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Iron Wire Mesh

Material : Iron

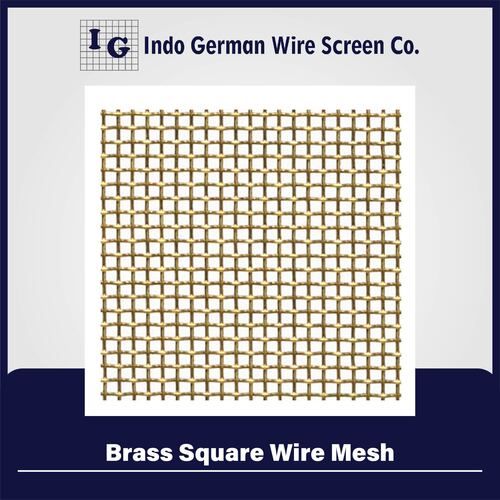

Brass Square Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Brass Square Wire Mesh

Material : Other, Brass

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry