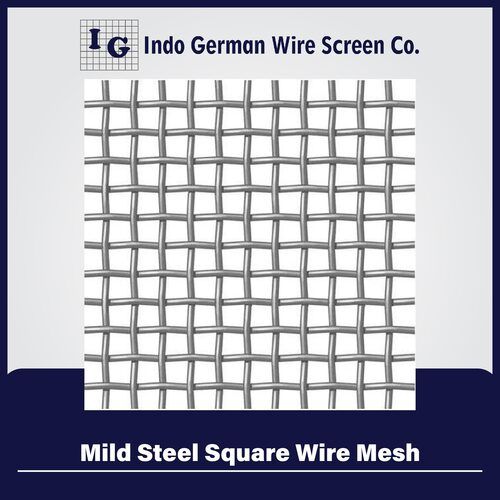

Mild Steel Rectangular Wire Mesh

Price 50 INR/ Unit

Mild Steel Rectangular Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Mild Steel

- Color

- Silver

Mild Steel Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Mild Steel Rectangular Wire Mesh

Mild steel is very sturdy and strong, finding multiple uses throughout structural applications. Mild steel has high tensile strength, high impact strength or toughness properties as well. Mild steel is readily weldable and most suitable for applications that require welding in fields like building and construction. Mild steel is known to be magnetic and hence Mild is most suited to those applications that may require some magnetic force to work. Mild steel alloys have good ductility and malleability and are used as parts of a piping system or in the automobile industry.Mild Steel Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofMild Steel Rectangular Wire Meshat unmatched quality and market leading prices.

Superior Durability and Finish

Our coated mild steel rectangular wire mesh features a resilient silver finish and a plain mesh style, delivering protection against corrosion and enhancing overall lifespan. This solution is engineered for performance even in demanding environments, with a strong structure that stands up to daily wear and tear.

Versatile Industrial Applications

Suitable for filtration, reinforcement, fencing, and partitioning, our steel wire mesh adapts to various industrial and commercial requirements. Its precise mesh type and configuration make it a preferred choice for both indoor and outdoor uses, ensuring adaptability and functional reliability.

FAQs of Mild Steel Rectangular Wire Mesh:

Q: How is the mild steel rectangular wire mesh manufactured?

A: The mesh is produced by weaving coated mild steel wires into a plain, rectangular pattern, resulting in a uniform and strong structure. Each mesh undergoes a surface treatment process, where a protective coating is applied to enhance its resistance to corrosion.Q: What are the common uses of mild steel rectangular wire mesh in various industries?

A: This wire mesh is commonly used for filtration, screening, fencing, reinforcement, shelving, and partitioning in sectors such as construction, agriculture, mining, and general manufacturing. Its versatility allows it to meet diverse operational requirements.Q: When should I select rectangular wire mesh over other mesh types?

A: Choose rectangular wire mesh when you require precise separation, unequal aperture dimensions, or enhanced directional strength, such as in sieves, partitions, or industrial filtration systems. Its design is especially useful for applications demanding tailored mesh openings and reliable performance.Q: Where can your wire mesh products be supplied from and delivered to?

A: As an established exporter, manufacturer, supplier, and trader from India, we can fulfill orders domestically across India and internationally. We ensure efficient logistics and safe handling for our wire mesh products to reach your location promptly.Q: What is the process for coating the mild steel mesh, and why is it essential?

A: After forming the wire mesh, a protective coating is applied using industrial processes that may include galvanizing, powder coating, or painting. The coating is crucial for preventing rust, extending durability, and preserving the meshs visual appeal.Q: How does the silver coated wire mesh benefit my project?

A: The silver coating not only enhances resistance to environmental factors like moisture and chemicals but also gives the mesh a sleek, professional appearance. This translates to lower maintenance, increased longevity, and improved overall value for your applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

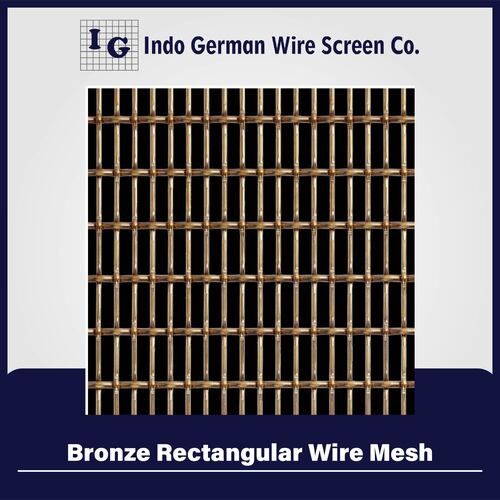

Bronze Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Bronze

Surface Treatment : Other, Polished, Uncoated

Mesh Type : Other , Rectangular Mesh

Material : Other, Phosphor Bronze / Bronze Alloy

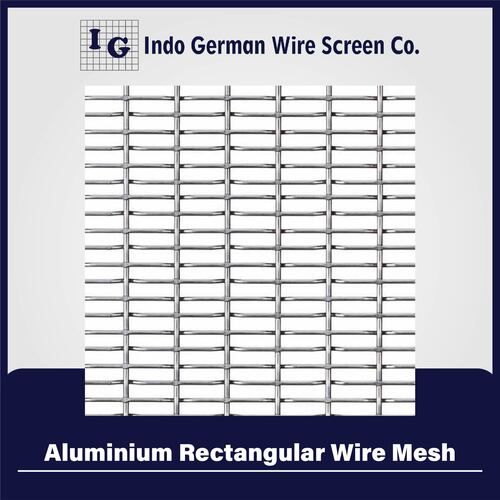

Aluminium Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Type : Aluminum Wire Mesh

Material : Aluminum

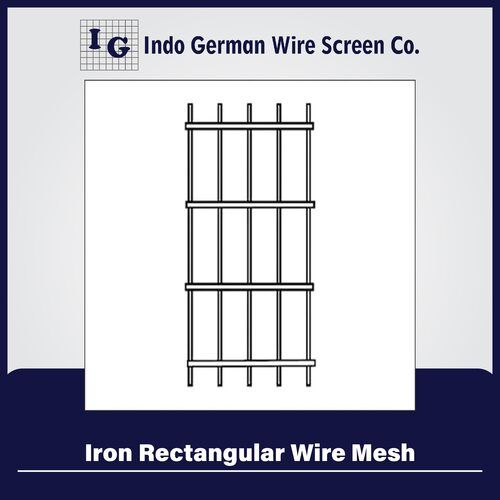

Iron Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Type : Iron Wire Mesh

Material : Iron

Tungsten Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Type : Other , Tungsten Wire Mesh

Material : Other, Tungsten

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry