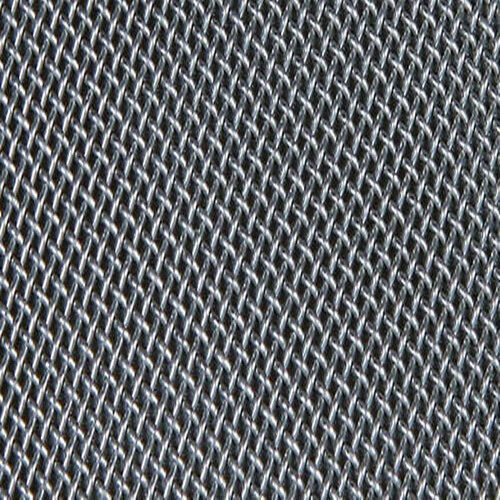

Nichrome A Fine Wire Mesh

Price 50 INR/ Unit

Nichrome A Fine Wire Mesh Specification

- Hole Shape

- Square

- Surface Treatment

- Polished

- Length

- 10 meters

- Aperture

- 0.3 mm

- Wire Gauge

- 36 SWG

- Product Type

- Fine Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Woven

- Material

- Nichrome A

- Alloy

- Nickel-Chromium

- Application

- Heating Element, Laboratory Sieving, Filtration, Industrial Furnaces

- Dimensions

- 1 meter x 10 meters

- Wire Diameter

- 0.193 mm

- Weight

- Approx. 1.5 kg (per roll)

- Color

- Silver

- Packing Type

- Roll

- Tensile Strength

- Strong

- Melting Point

- 1400°C

- Minimum Order Quantity

- 1 Roll

- Temperature Resistance

- Up to 1200°C

- Corrosion Resistance

- High

- Electrical Conductivity

- Good

About Nichrome A Fine Wire Mesh

Nichrome is the alloy of nickel and chrome and, according to different chemical compositions, can be divided into Cr20Ni80, Cr15Ni60 and Cr20Ni35. Nichrome is made of the nichrome wire and has outstanding ductility, oxidation resistance, high tensile strength, sulphur resistance and other features. Nichrome A Fine Wire mesh or wire cloth is thin woven wire meshes with mesh from 11 to 500 500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch). Nichrome A Fine Wire netting can have aperture from 0.0254 mm to 23.37 mm (0.001 inch to 0.92 inch) and when the wire diameter becomes thinner the aperture will be larger. Nichrome A Fine Wire Mesh can be used in elevated temperature applications, due to excellent functioning in higher temperatures. Nichrome A Fine Wire mesh is a versatile wire mesh having wide application in industrial, commercial and decoration.

Exceptional Thermal Endurance

With a temperature resistance of up to 1200C and a melting point of 1400C, Nichrome A Fine Wire Mesh caters to high-heat applications such as heating elements and industrial furnaces. The mesh maintains structural integrity and function even under prolonged exposure to extreme temperatures, making it a dependable choice for various industries.

Superior Durability and Corrosion Resistance

Nichrome As fine wire core ensures both strong tensile strength and impressive corrosion resistance. These properties enhance its longevity and reliability in harsh environments, making the mesh fit for laboratory sieving, industrial filtration, and other applications that demand resilience against chemical or thermal stresses.

FAQs of Nichrome A Fine Wire Mesh:

Q: How is Nichrome A Fine Wire Mesh installed for heating elements or filtration systems?

A: Installation typically involves unrolling the mesh to the required length (1 meter x 10 meters per roll) and fitting it into your application, such as mounting within a heating chamber or attaching it to a frame for filtration. Its flexible woven structure makes it easy to cut and shape as needed.Q: What industries commonly use this Nichrome A mesh, and why?

A: This mesh is widely utilized in heating elements, laboratory sieving, filtration, and industrial furnaces due to its ability to withstand high temperatures, resist corrosion, and maintain good electrical conductivity.Q: When should I consider choosing Nichrome A mesh over other materials?

A: Opt for Nichrome A mesh when your application requires robust temperature resistance, high tensile strength, corrosion resistance, and efficient electrical conductivityespecially in high-heat or chemically aggressive environments.Q: Where can I source Nichrome A Fine Wire Mesh rolls in India?

A: These mesh rolls are available from leading exporters, manufacturers, suppliers, and traders across India, who offer direct purchase (minimum order of 1 roll) and can provide customized packing if needed.Q: What is the significance of the 36 SWG gauge and 0.3 mm aperture in usage?

A: The 36 SWG gauge indicates fine wire thickness (0.193 mm), while the 0.3 mm aperture allows for effective sieving and filtration without compromising structural strength, making it ideal for both laboratory and industrial applications.Q: How does the polished surface treatment benefit the mesh?

A: The polished finish enhances the meshs corrosion resistance and facilitates easier cleaning, which is especially important in laboratory and filtration settings where material purity is vital.Q: What is the process for ordering the mesh if custom dimensions are required?

A: While standard rolls are 1 meter x 10 meters, manufacturers and exporters often accept custom orders. Its recommended to contact the supplier directly to discuss your specific dimension or packing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Bronze Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Plain Weave

Surface Treatment : Mill Finish

Color : Bronze

Mesh Type : Other , Woven Mesh

Mild Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Woven Mesh

Surface Treatment : Other, Galvanized or Plain Finish

Color : Metallic Silver

Mesh Type : Other , Fine Wire Mesh

Monel 400 Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Woven Mesh

Surface Treatment : Other, Annealed

Color : Metallic Grey

Mesh Type : Other , Fine Mesh

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Woven

Surface Treatment : Other, Annealed

Color : Silvergrey

Mesh Type : Other , Ultrafine mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry