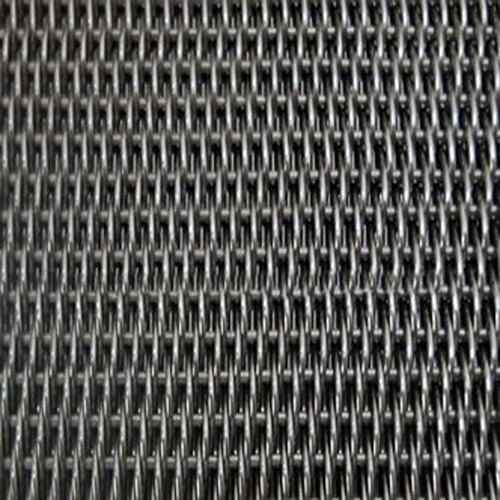

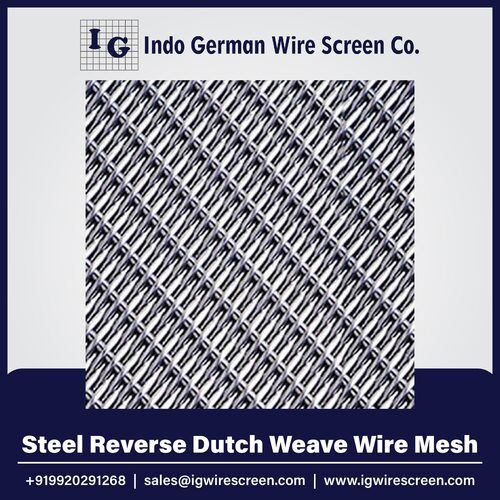

Steel Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Steel Reverse Dutch Weave Wire Mesh Specification

- Wire Gauge

- 16 - 30 SWG

- Hole Shape

- Rectangular

- Surface Treatment

- Coated

- Length

- 15 - 30 Meter Rolls

- Aperture

- 0.05 mm - 2 mm

- Product Type

- Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Steel

- Alloy

- Available on request

- Application

- Other

- Dimensions

- Customizable

- Wire Diameter

- 0.2 mm - 0.5 mm

- Weight

- Variable, as per custom size

- Color

- Silver

- Temperature Resistance

- Up to 800°C (dependent on steel grade)

- Standard Width

- 0.5 m to 2 m

- Corrosion Resistance

- Yes, after coating

- Standards

- ASTM, ISO Available

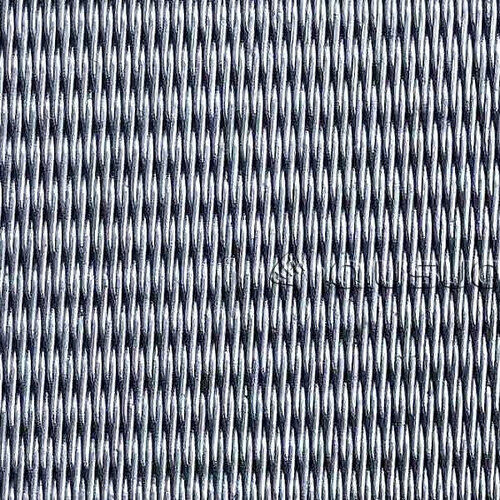

- Weave Type

- Reverse Dutch Weave

- Packing Type

- Rolls or as per requirement

- End Type

- Cut Edge

- Tensile Strength

- High

- Open Area

- Low (Dense mesh suitable for filtration)

Steel Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Steel Reverse Dutch Weave Wire Mesh

Steel Reverse Dutch Weave Wire Meshhas more thin warp wires and fewer, but larger, weft wires as this structure provides a high degree of stability and optimal resistance to high pressure.Reverse Dutch weave wire meshis specially designed for filtering and has a very high level of mechanical load and a high flow and porosity level.The same weave as Plain Dutch except the warp and Shute wires are reversed; i.e., the warp wires have a smaller diameter than the Shute wires. The type of cloth is mechanically highly sturdy with a high throughput and it does particularly well in high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are vital.We offer an exclusive range ofSteel Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Precision Filtration

Engineered using the Reverse Dutch Weave technique, this wire mesh is designed to facilitate fine filtration thanks to its low open area and dense structure. The steel wires interlock to restrict particulate passage, making it ideal for industries requiring high-efficiency separation.

Robust Performance in Extreme Conditions

Thanks to its high tensile strength and specialized coating, the mesh withstands temperatures up to 800C (depending on the alloy) and offers superior corrosion resistance. This durability ensures reliable operation even in demanding environments and with aggressive materials.

Custom Manufacturing & Compliance

Offered in a range of widths, wire gauges, and customized rolls, the mesh adheres to international standards such as ASTM and ISO. With options for custom dimensions and alloys, suppliers from India provide tailored solutions for various industrial filtration needs.

FAQs of Steel Reverse Dutch Weave Wire Mesh:

Q: How is Reverse Dutch Weave different from other wire mesh weaves?

A: Reverse Dutch Weave employs thicker warp wires and finer weft wires, creating a denser mesh structure with minimal open area. This construction enhances both mechanical strength and filtration efficiency, distinguishing it from conventional mesh weaves.Q: What are the typical applications for Steel Reverse Dutch Weave Wire Mesh?

A: This wire mesh is commonly used in fine industrial filtration processes, including chemical processing, water treatment, pharmaceutical production, and food industry filtration, where precise particle separation is essential.Q: When should a coated surface treatment be selected for this mesh?

A: A coated surface treatment is recommended when the mesh will be exposed to corrosive environments, increasing its lifespan and maintaining performance. Coating provides additional resistance to oxidation and chemical attack, especially important in harsh industrial settings.Q: Where can this mesh be supplied from and are export services available?

A: Steel Reverse Dutch Weave Wire Mesh is produced and supplied by manufacturers, exporters, and traders in India. Global export services are available, allowing for international shipping according to customer requirements.Q: What process is followed to customize dimensions or alloy for this product?

A: Customization involves selecting desired width, length, aperture size, and wire diameter during order placement. Clients may also request specific steel alloys, adjusting temperature and corrosion resistance to their application needs.Q: How does the high tensile strength of this mesh benefit industrial filtration?

A: High tensile strength ensures the mesh withstands mechanical stress and maintains its integrity during filtration, especially where high pressure and heavy loads are involved. This reliability reduces downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

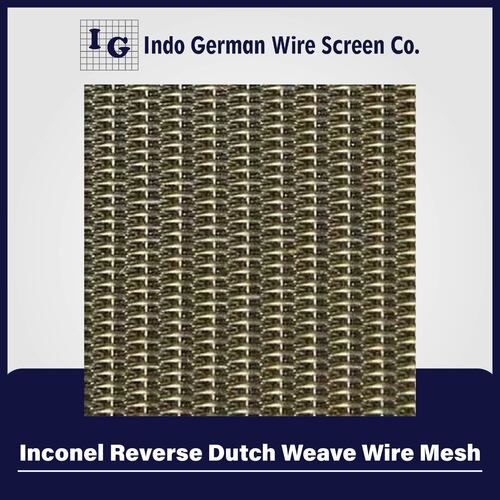

Inconel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Type : Other , Reverse Dutch Weave

Color : Silver

Surface Treatment : Coated

Mild Steel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Cloth

Mesh Type : Other , Reverse Dutch Weave

Color : Silver

Surface Treatment : Coated

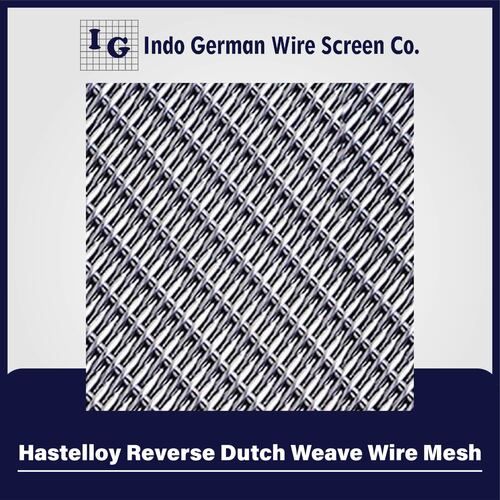

Hastelloy Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Type : Other , Reverse Dutch Weave

Color : Silver

Surface Treatment : Coated

Monel 400 Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Type : Other , Reverse Dutch Weave

Color : Silver

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry