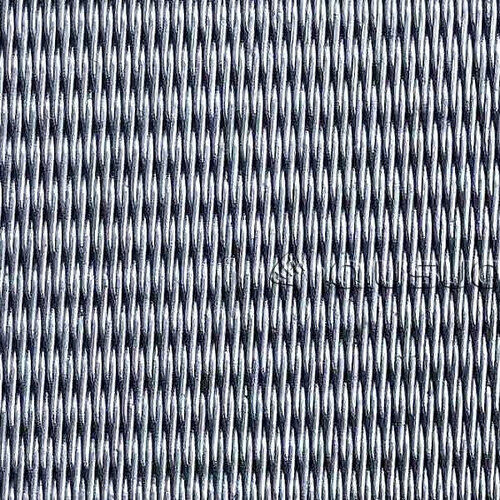

Nickel Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Nickel Reverse Dutch Weave Wire Mesh Specification

- Hole Shape

- Rectangular

- Wire Gauge

- Standard 14 SWG to 28 SWG (customized available)

- Length

- Available in 1-30 meters or as specified

- Surface Treatment

- Coated

- Aperture

- 0.10 mm 2.00 mm

- Product Type

- Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Nickel 200 / Nickel 201

- Application

- Filtration, Chemical Processing, Battery Electrode, Gas and Liquid Separation

- Dimensions

- Width: 30 cm 200 cm

- Wire Diameter

- 0.20 mm 2.00 mm

- Weight

- 1 kg/m 9 kg/m

- Color

- Silver

- Weave Type

- Reverse Dutch Weave

- Corrosion Resistance

- Excellent in acid, alkaline, and neutral media

- Tensile Strength

- High tensile strength

- Packing

- Rolls wrapped with moisture-proof paper, or customized

- Purity

- Nickel content >99% (Typical for Nickel 200/201 grades)

- Edge Type

- Cut Edge / Selvage Edge

- Standards

- ASTM, ISO

- Temperature Resistance

- Up to 600°C

- Opening Rate

- High flow, fine filtration

Nickel Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Reverse Dutch Weave Wire Mesh

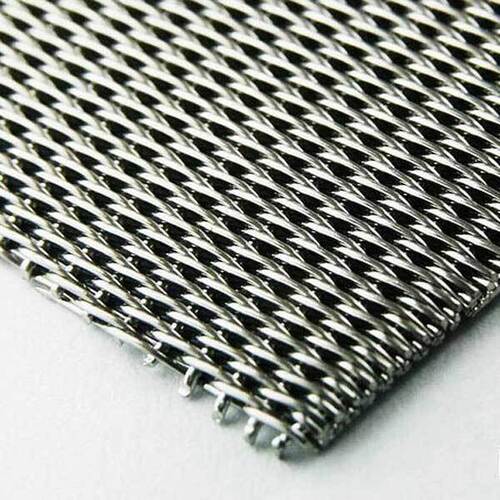

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc.The same weave as Plain Dutch except the warp and Shute wires are reversed; i.e. the warp wires have a smaller diameter than the Shute wires. The type of cloth is mechanically highly sturdy with a high throughput and it does particularly well in high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are vital.We offer an exclusive range ofNickel Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Superior Corrosion Resistance

Crafted from Nickel 200/201, this wire mesh excels in resisting corrosion against acids, alkalis, and neutral media. This feature broadens its usability in chemical processing plants and other demanding environments, ensuring uninterrupted performance and longevity. Its high nickel purity and protective coated surface keep it resilient to chemical attack.

High-Temperature Endurance

With a temperature tolerance up to 600C, Nickel Reverse Dutch Weave Wire Mesh operates efficiently in thermal-intensive applications. Its inherent stability and high tensile strength enable it to maintain structural integrity, making it suitable for filtration and separation tasks even under substantial heat.

Optimized Filtration Performance

Utilizing the reverse Dutch weave design, the mesh promotes high flow rates while delivering precise particle filtration. This optimizes the separation of fluids and gases and proves especially beneficial in battery electrode manufacture as well as industrial filtration systems. Customizable aperture sizes ensure tailored filtration efficiency.

FAQs of Nickel Reverse Dutch Weave Wire Mesh:

Q: How is Nickel Reverse Dutch Weave Wire Mesh utilized in industrial filtration systems?

A: Nickel Reverse Dutch Weave Wire Mesh is applied in filtration systems to allow high flow rates while achieving fine particle separation. Its robust construction ensures reliable filtration for liquids and gases in sectors including chemical processing, batteries, and laboratory separations.Q: What process is used to manufacture the reverse Dutch weave structure in nickel wire mesh?

A: The reverse Dutch weave is produced by interlacing thicker warp wires with thinner weft wires, which increases mechanical strength and enhances filtration precision. This process ensures the mesh delivers high tensile strength for complex filtering needs.Q: When should you consider using Nickel Reverse Dutch Weave Wire Mesh over other materials?

A: Nickel Reverse Dutch Weave Wire Mesh is recommended when the application demands excellent corrosion resistance, high-temperature stability, and precise filtrationsuch as in corrosive chemical environments, high-temperature processing, or advanced battery technology.Q: Where can Nickel Reverse Dutch Weave Wire Mesh be installed for optimal performance?

A: It is suitable for installation in chemical plants, battery manufacturing units, industrial gas and liquid separation modules, and any environment where both chemical durability and fine filtration are required.Q: What are the benefits of high nickel purity in this wire mesh?

A: High nickel purity (>99%) ensures superior corrosion resistance, thermal stability, and prolonged mesh life. It also enhances performance in applications requiring minimal contamination and consistent filtration efficiency.Q: How is the mesh shipped and packaged to maintain quality?

A: The wire mesh is packed in rolls wrapped with moisture-proof paper or customized packaging solutions to protect it from environmental moisture, mechanical damage, and contamination during transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

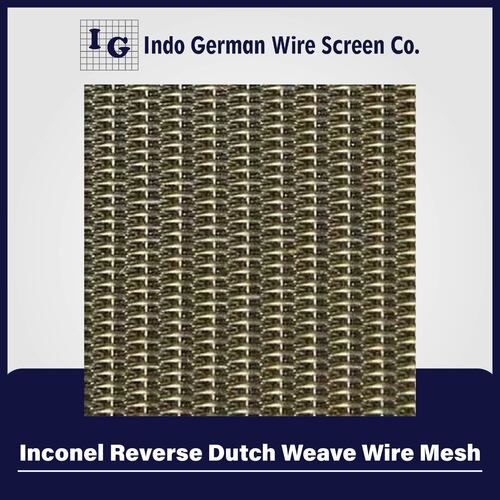

Inconel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Color : Silver

Surface Treatment : Coated

Product Type : Wire Mesh

Aluminium Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Aluminum

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

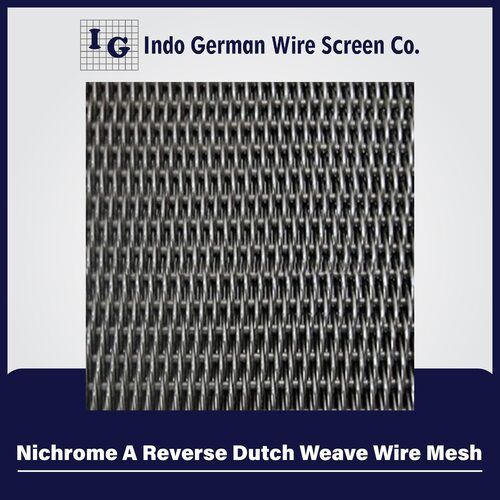

Nichrome A Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Nichrome

Color : Silver

Surface Treatment : Coated

Product Type : Wire Mesh

Monel 400 Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Monel

Color : Silver

Surface Treatment : Coated

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry