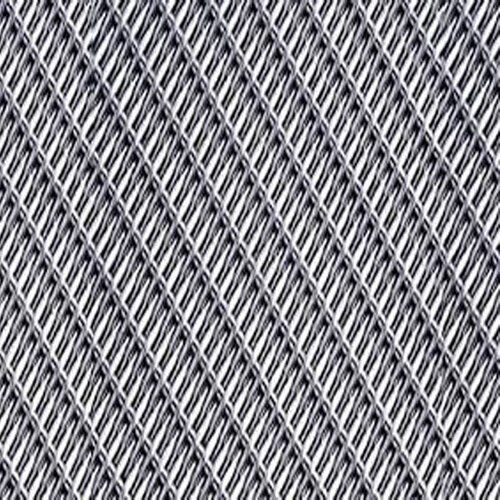

Nickel Dutch Weave Wire Mesh

Price 50 INR/ Unit

Nickel Dutch Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Dutch Weave Wire Mesh

- Material

- Nickel

- Application

- Other

- Color

- Gray

Nickel Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Dutch Weave Wire Mesh

Theplain Nickel dutch weavehas a high filtering level and high pressure load resistance. ThisNickel dutch weave wire meshis strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.Nickel dutch weave wire meshis widely utilized as filter fittings for chemical industry, medicine, petroleum, scientific research units due to its stable and fine filtration ability. It ismostly favoured in corrosive environments such as filtration of liquids, gas, etc. Nickel is many and has high stability and reliable filtration properties. Nickel is mostly preferred in corrosive environments such as filtration of liquids, gas, etc.

Superior Filtration Performance

The Dutch weave pattern of our nickel wire mesh is optimally designed for fine filtration and separation tasks. Its robust construction ensures reliability under high pressure while effectively managing particle retention. The coated surface also offers enhanced resistance against corrosion and aggressive chemicals.

Versatile Industrial Applications

Our Nickel Dutch Weave Wire Mesh serves industries such as chemical processing, pharmaceuticals, food and beverage, and petrochemicals. Its high durability and unique weave allow it to operate efficiently in harsh environments, meeting stringent requirements for critical processes and purity.

FAQs of Nickel Dutch Weave Wire Mesh:

Q: How is Nickel Dutch Weave Wire Mesh manufactured?

A: Nickel Dutch Weave Wire Mesh is produced by weaving nickel wires in a specialized Dutch pattern. The process involves precise interlacing to create a fine mesh suitable for advanced filtration. Post-weaving, the mesh undergoes a coating treatment to enhance its surface resilience and longevity.Q: What benefits does the coated surface provide for this wire mesh?

A: The coated surface on Nickel Dutch Weave Wire Mesh offers improved corrosion resistance, especially in environments exposed to chemicals or moisture. This protective layer increases the meshs durability, extends its service life, and maintains filtration effectiveness.Q: When should I choose Nickel Dutch Weave Wire Mesh for my application?

A: This mesh is ideal when you require fine filtration under demanding conditions, such as in chemical, pharmaceutical, or petrochemical industries. It should be chosen when precise particle retention and resistance to harsh environments are critical to your processs success.Q: Where can Nickel Dutch Weave Wire Mesh be used?

A: Nickel Dutch Weave Wire Mesh is commonly used in filtration systems, separation processes, catalyst support, and sieving operations across sectors like chemical processing, oil and gas refining, and food and beverage production.Q: What is the main usage of Dutch Weave Wire Mesh made from nickel?

A: The primary usage of nickel Dutch weave wire mesh is for filtration and separation of fine particles. Its weave structure ensures optimal flow control while its nickel composition provides strength and resistance to corrosion, essential for sensitive industrial processes.Q: How does this mesh benefit exporters, manufacturers, suppliers, and traders in India?

A: By providing a reliable and durable product, Nickel Dutch Weave Wire Mesh allows Indian exporters, manufacturers, suppliers, and traders to serve local and global markets. Its superior quality meets international standards and caters to clients seeking advanced filtration solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dutch Weave Wire Mesh Category

Copper Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Copper

Product Type : Wire Mesh

Surface Treatment : Coated

Mesh Style : Plain Mesh

Stainless Steel Welded Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Wire Mesh

Surface Treatment : Coated

Mesh Style : Plain Mesh

Titanium Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Titanium

Product Type : Wire Cloth

Surface Treatment : Coated

Mesh Style : Plain Mesh

Mild Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Product Type : Wire Mesh

Surface Treatment : Coated

Mesh Style : Other , Dutch Weave Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry