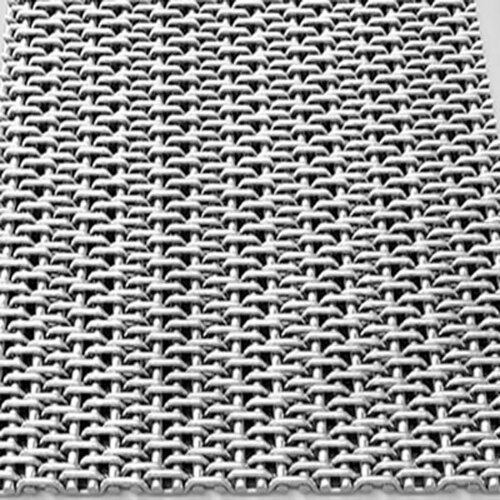

Titanium Dutch Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Titanium Dutch Weave Wire Mesh Specification

- Length

- Available in rolls or cut pieces, standard up to 30 meters

- Surface Treatment

- Coated

- Aperture

- Fine, as per Dutch weave specification (typically 5100 micron)

- Hole Shape

- Rectangular

- Wire Gauge

- Customizable per requirement

- Product Type

- Wire Cloth

- Mesh Type

- Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Titanium

- Alloy

- Titanium Grade 2/Grade 5

- Application

- Other

- Dimensions

- Standard widths: 1m, 1.2m, or as specified

- Wire Diameter

- Ranges from 0.02 mm to 0.56 mm

- Weight

- Varies by wire diameter and mesh dimensions

- Color

- Gray

- Standard

- ASTM B348, ASTM F67/F136

- Temperature Resistance

- Suitable for high temperature up to 600°C

- Filtration Precision

- Capable of micro-filtration with high structural integrity

- Corrosion Resistance

- Excellent resistance to acids, alkalis, and chlorides

- Packing Type

- Plastic film and wooden case

- Edge Type

- Plain/No selvage or with reinforced edge

- Roll Size

- Standard roll: 1m x 30m or as customized

- Tensile Strength

- High tensile strength due to titanium properties

Titanium Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Titanium Dutch Weave Wire Mesh

Titanium is known for its high durability, light weight, high strength, and corrosion-resistant properties. The Titanium metal is resistant to saltwater, metallic salts, hydroxides, chromic acids, chlorides, nitric acids, organic acids, and dilute alkalis.Titanium dutch weave wire mesh or wire nettingis a type of weave with larger warp wires than the weft wires. InDutch wire cloth,the main feature is the warp and weft wire diameter thereby forming a firm and strong cloth producing a cloth with no readily visible apertures. The greater contrast density improves net thickness and filtering accuracy and the mesh will have greater life and will have a more significant increase than the average square mesh.Superior Performance for Filtration Needs

Utilizing the unique properties of titanium, this Dutch Weave Wire Mesh delivers outstanding results in filtration systems. Its micro-aperture structure ensures precision filtration for fine particles, while maintaining high mechanical strength and durability. The mesh is suitable for chemical, petrochemical, aerospace, and other demanding sectors requiring reliable micro-filtration.

Durable Construction and Custom Options

Each roll of Titanium Dutch Weave Wire Mesh can be tailored in wire diameter, width, and length to meet specific requirements. Reinforced edges are available for added longevity, with the choice of standard sizes (1m x 30m) or custom dimensions. The mesh features a gray, coated surface and is packed securely in plastic film and wooden cases for safe delivery.

FAQs of Titanium Dutch Weave Wire Mesh:

Q: How is Titanium Dutch Weave Wire Mesh used in industrial filtration applications?

A: Titanium Dutch Weave Wire Mesh is primarily used in filtration systems where micro-filtration is required. Its fine aperture (typically 5100 microns) efficiently separates tiny particulates in chemical, pharmaceutical, and water treatment processes, making it suitable for environments demanding high purity and durability.Q: What process is used to manufacture Titanium Dutch Weave Wire Mesh?

A: The mesh is manufactured by weaving fine titanium wiresavailable in custom diameters from 0.02 mm to 0.56 mmusing the Dutch weave style. This method interlaces thicker warp wires with fine weft wires, producing a structure with high filtration precision and mechanical strength. All production adheres to ASTM B348 and ASTM F67/F136 standards.Q: When should reinforced edges be chosen for wire mesh rolls?

A: Reinforced edges are recommended for installations requiring frequent handling, additional mechanical support, or prolonged use in high-stress environments. They help maintain the meshs structural integrity during repeated usage or when exposed to heavy-duty filtration operations.Q: Where can Titanium Dutch Weave Wire Mesh be effectively utilized?

A: This mesh is effective in industries like chemical processing, environmental engineering, food and beverage, aerospace, and pharmaceuticals. Its excellent resistance to corrosive substances and high temperatures makes it highly suitable for these demanding sectors.Q: What are the key benefits of using titanium material for wire mesh?

A: Titanium offers superior corrosion resistance to acids, alkalis, and chlorides, exceptional high-temperature stability up to 600C, and remarkable tensile strength. These benefits allow the mesh to function reliably in harsh environments while maintaining its filtration effectiveness over extended periods.Q: How is the wire mesh packed and delivered to ensure safety?

A: Titanium Dutch Weave Wire Mesh is protected with plastic film to prevent moisture exposure and packed in sturdy wooden cases. This packaging method ensures that products remain intact during transit and are delivered safely to customers.Q: Can the roll size and wire gauge of the mesh be customized?

A: Yes, both roll sizes and wire gauges of the titanium mesh can be tailored according to client specifications. Standard rolls are available in dimensions of 1m x 30m, but custom widths or lengths, as well as wire diameters, can be provided for specialized filtration purposes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dutch Weave Wire Mesh Category

Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Gray

Application : Other

Mesh Style : Plain Mesh

Stainless Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Gray

Application : Other

Mesh Style : Plain Mesh

Iron Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Gray

Application : Other

Mesh Style : Other , Dutch Weave Wire Mesh

Brass Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Gray

Application : Other

Mesh Style : Other , Dutch Weave Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry