Nickel Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Nickel Five Shed Twill Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Nickel Five Shed Twill Weave Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Nickel

- Application

- Other

- Color

- Silver

Nickel Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Five Shed Twill Weave Wire Mesh

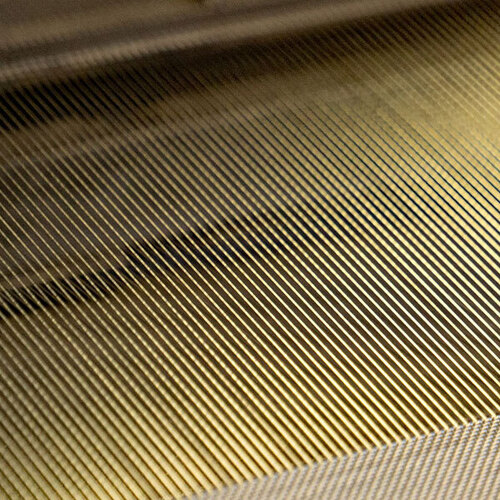

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc.Nickel Five Shed Twill weave wire meshis a welded wire mesh panel precisely manufactured by knitting thin diameter wires to form a square mesh hole. TheNickel Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.We offer an exclusive range ofNickel Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Superior Construction and Performance

Nickel Five Shed Twill Weave Wire Mesh combines the strength of nickel with a precision weave. Its shed twill weave pattern ensures robust mechanical stability, making it ideal for filtration and separation in environments facing extreme conditions. The coated surface improves resistance to corrosion and wear, enhancing its performance in industrial settings.

Versatile Applications Across Industries

This wire mesh is suitable for a wide range of uses, including chemical processing, aerospace, energy, and pharmaceuticals. Its unique mesh structure allows precise control over flow, filtration, and separation, making it a preferred choice for industries that demand reliability and durability under challenging conditions.

FAQs of Nickel Five Shed Twill Weave Wire Mesh:

Q: How is the Nickel Five Shed Twill Weave Wire Mesh manufactured?

A: This wire mesh is crafted using a shed twill weaving process with pure nickel wires, resulting in a plain mesh style. Advanced machinery weaves the wires into a robust structure, after which a surface coating is applied to enhance corrosion resistance and longevity.Q: What are typical uses for Nickel Five Shed Twill Weave Wire Mesh?

A: The mesh is commonly employed in filtration, separation, and reinforcement tasks within industries such as chemical processing, aerospace, energy, and pharmaceuticals, where its durability and corrosion resistance are highly advantageous.Q: When should you choose Nickel Five Shed Twill Weave Wire Mesh over alternative materials?

A: Select this mesh when your application demands high temperature resistance, superior corrosion protection, and structural reliability, particularly in environments with harsh chemicals or extreme thermal cycles.Q: Where is this wire mesh predominantly supplied from in India?

A: Leading exporters, manufacturers, suppliers, and traders across India provide this wire mesh, ensuring readily available stock for both domestic and international clients.Q: What is the process for surface treatment on the Nickel Mesh?

A: The mesh undergoes a specialized coating process to enhance its resistance to corrosion, chemicals, and environmental wear, which helps maintain its integrity even in aggressive operating conditions.Q: How does the shed twill weave pattern benefit the meshs performance?

A: The shed twill weave pattern offers increased flexibility and strength, resulting in even load distribution and improved resistance to deformation under pressure or stress.Q: What are the main benefits of using Nickel Five Shed Twill Weave Wire Mesh?

A: Key benefits include outstanding resistance to corrosion and heat, long service life, structural robustness, and adaptability for customized industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Bronze Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Bronze

Material : Other, Bronze

Mesh Type : Other , Woven

Tungsten Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Material : Metal Alloys

Mesh Type : Other , Woven

Nichrome A Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Material : Other, Nichrome

Mesh Type : Other , Nichrome Mesh Wire

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry