Tungsten Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Tungsten Five Shed Twill Weave Wire Mesh Specification

- Wire Gauge

- Available in various gauges as per requirement

- Surface Treatment

- Coated

- Aperture

- 0.02 mm to 2 mm (selectable)

- Length

- Standard roll length 30m (customizable)

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Woven

- Mesh Style

- Five Shed Twill Weave

- Material

- Metal Alloys

- Alloy

- 99.95% Pure Tungsten

- Application

- Other

- Dimensions

- Standard width up to 1.2m (custom sizes available)

- Wire Diameter

- 0.025 mm 0.6 mm

- Weight

- Varies according to size and specification

- Color

- Silver

- Operating Temperature

- Up to 3400°C

- Acid Resistance

- Superior

- Weave Type

- Five Shed Twill Weave

- Melting Point

- 3422°C

- Packing

- Rolled with moisture-proof paper and wooden case

- Edge Type

- Plain or Selvage

- Corrosion Resistance

- Excellent

Tungsten Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Tungsten Five Shed Twill Weave Wire Mesh

Tungsten is an extremely hard metallic element that has an extremely high melting point and is corrosion resistant in many harsh environments. Tungsten is resistant to oxidation attack and corrosion in acidic and alkaline media and is used in elevated temperature filtration applications.Tungsten Five Shed Twill weave wire meshis a welded wire mesh panel precisely manufactured by knitting thin diameter wires to form a square mesh hole. TheTungsten Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.Tungsten Five Shed Twill Weave Wire Mesh can be Woven and Welded. We offer an exclusive range ofTungsten Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Exceptional Performance in Extreme Conditions

This wire mesh is specifically designed to withstand demanding environments, including exposure to high temperatures and harsh chemicals. Featuring a melting point of 3422C and unrivaled corrosion and acid resistance, it remains reliable across numerous industrial applications, ensuring longevity and sustained performance.

Precision Engineering with Customizable Features

Manufactured with a five shed twill weave, the mesh delivers remarkable tensile strength and flexibility. Available in standard or customized sizes, wire diameters, and apertures, users can select specifications that meet their exact requirements, achieving both precision filtration and robust mechanical stability.

FAQs of Tungsten Five Shed Twill Weave Wire Mesh:

Q: How is the Tungsten Five Shed Twill Weave Wire Mesh manufactured?

A: The mesh is produced using high-purity tungsten wires woven expertly in a five shed twill pattern, which provides improved flexibility and mechanical strength. Edge types can be specified as either plain or selvage, ensuring suitability for different installation needs.Q: What advantages does the five shed twill weave offer compared to other weave patterns?

A: Five shed twill weave enhances both tensile strength and flexibility, allowing the mesh to handle mechanical stresses better. It also delivers consistent square aperture shapes, promoting efficient filtration and structural integrity even in demanding conditions.Q: When should I choose this tungsten wire mesh for industrial applications?

A: This product is ideal for environments requiring exceptional heat stability, corrosion resistance, or acid-proof properties, such as high-temperature furnaces, chemical processing units, and precision filtration systems. Its reliability at temperatures up to 3400C makes it suitable for extreme conditions.Q: Where can the Tungsten Five Shed Twill Weave Wire Mesh be used?

A: It finds applications in metallurgy, aerospace, chemical engineering, filtration, and electronics industries. Its ability to withstand harsh acids and high temperatures enables its use in settings where conventional meshes may fail.Q: What is the process for ordering custom sizes or aperture dimensions?

A: Custom dimensions can be requested during the ordering process. Share your requirements for roll length, width (up to 1.2m), wire diameter (0.025 mm 0.6 mm), or aperture size (0.02 mm 2 mm) with the manufacturer, supplier, or exporter for a tailored solution.Q: How does packing and delivery ensure product integrity?

A: Each roll is securely packed in moisture-proof paper and enclosed in sturdy wooden cases, safeguarding the mesh from environmental damage and physical deformation while in transit and storage.Q: What benefits does using pure tungsten alloy wire mesh provide?

A: Using 99.95% pure tungsten ensures maximum durability, outstanding heat resilience, and resistance to most corrosive agents, contributing to longer service life and consistent performance in challenging industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

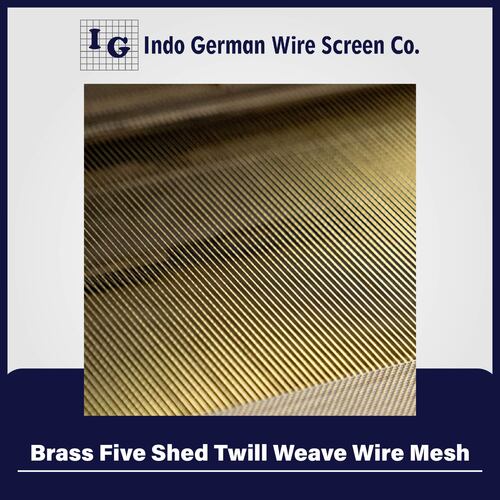

Brass Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Golden

Mesh Type : Other , Five Shed Twill Weave

Material : Other, Brass

Surface Treatment : Coated

Aluminium Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Mesh Type : Other , Twill Weave

Material : Aluminum

Surface Treatment : Coated

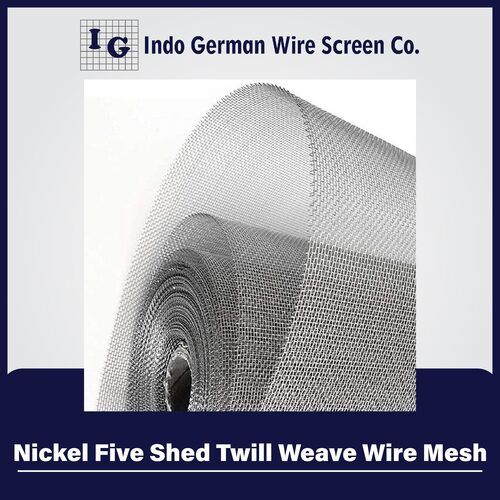

Nickel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Type : Other , Nickel Five Shed Twill Weave Wire Mesh

Material : Other, Nickel

Surface Treatment : Coated

Stainless Steel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Stainless Steel

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry