Perforated Metal Screens

Price 50 INR/ Square Foot

Perforated Metal Screens Specification

- Shape

- Circular

- Usage

- industrial

- Material

- Stainless Steel Wire

- Technique

- Perforated

- Product Type

- Perforated Metal Screens

- Thickness

- 0.5 - 5 Millimeter (mm)

- Application

- For Industrial Use

Perforated Metal Screens Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Export Market(s)

- Western Europe

- Main Domestic Market

- All India

About Perforated Metal Screens

With the support of our diligent employees, we are manufacturing, supplying and exporting Perforated Metal Screens. They are simple sheet metals that have been manually or mechanically punched to create holes. Earlier it was used as an efficient means of separating coal, but now it is used for different purposes. These are manufactured under the supervision of our experts using high-grade raw materials and latest technologies. They are preferred more because of their ability to lower sound levels and reducing the health effects of noise. Perforated Metal Screens are widely used in industries including material development, construction, automotive and chemical industry.

Special Features ofPerforated Metal Screens:

- These stainless steel screens are featured with Dutch weaved pattern.

- Extensive applications in paint, paper, oil refining and food processing arena

- Equipped with round holes, hot dip galvanized surface

- Staggered or straight perforation technique, silver color, abrasion and wear proof

Product Details

|

Hole Shape |

Circular |

|

Material Grade |

SS 304, 316 |

|

Weave Style |

Plain |

|

Technique |

Perforated |

|

Material |

GI, MS, SS, Aluminium |

Versatile Industrial Solution

Perforated Metal Screens are engineered for robust industrial applications, delivering reliable separation and filtration capabilities. Their stainless steel construction ensures resistance to corrosion, providing long-term performance in demanding environments.

Precision Engineering and Customization

With thickness options between 0.5 and 5 mm and a circular design, these screens can be customized to suit specific operational requirements. The precision perforated technique guarantees consistent aperture sizes ideal for various industrial processes.

FAQs of Perforated Metal Screens:

Q: How are perforated metal screens manufactured for industrial use?

A: These screens are produced through a perforation process, where stainless steel wire is mechanically punched or stamped to create precise holes. This process ensures uniformity and strength suitable for rigorous industrial applications.Q: What are the main benefits of using stainless steel perforated metal screens in industrial settings?

A: Stainless steel perforated screens offer exceptional resistance to corrosion, mechanical strength, and longevity. Their design enhances airflow or filtration efficiency, making them ideal for industries like chemical processing, pharmaceuticals, and food production.Q: Where can perforated metal screens be applied within an industrial environment?

A: They are commonly installed in filtration systems, protective barriers, separation units, and ventilation systems across various industries, ensuring product purity and worker safety.Q: When should I consider choosing a circular perforated metal screen over other shapes?

A: Circular perforated screens are optimal when uniform distribution of force or filtration is required, such as in centrifugal machines, sieving processes, or round containment units.Q: What is the recommended thickness for different industrial applications?

A: The thickness should align with usage demands: lighter screens (0.51 mm) are ideal for fine filtration, while thicker screens (up to 5 mm) are preferred for heavy-duty separation or protection purposes.Q: How do I determine the right perforation size and pattern for my operation?

A: Consult with the supplier, providing details of your application. They will recommend hole sizes and patterns based on required flow rates, particle sizes, and mechanical load-bearing needs.Q: What advantages does sourcing from an Indian exporter and manufacturer provide?

A: Choosing an Indian exporter or manufacturer offers cost-effective solutions, access to high-quality standards, and customizable products backed by responsive service and timely delivery to international markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Vibro Screen

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Material : Stainless Steel

Product Type : Sifter Sieves For Vibro Screen

Usage : industrial

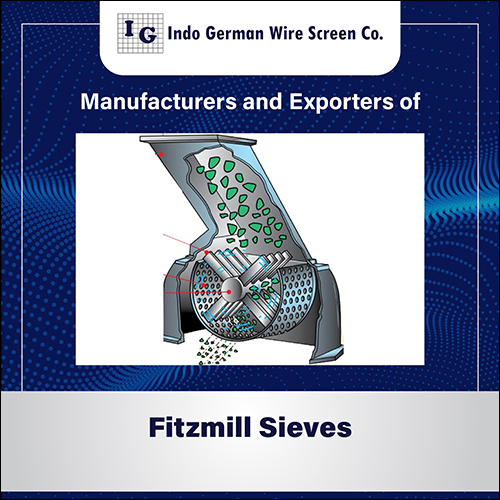

Fitzmill Sieves

Price 1000 INR / Foot

Minimum Order Quantity : 10

Material : Stainless Steel

Product Type : Fitzmill Sieves

Usage : industrial

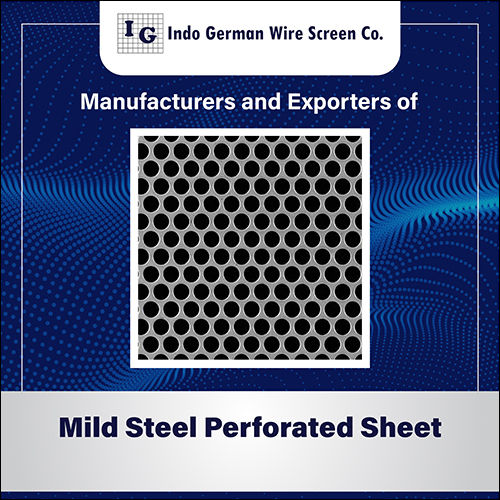

Mild Steel Perforated Sheet

Price Range 1000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other , Mild Steel

Product Type : Perforated Sheet

Usage : industrial

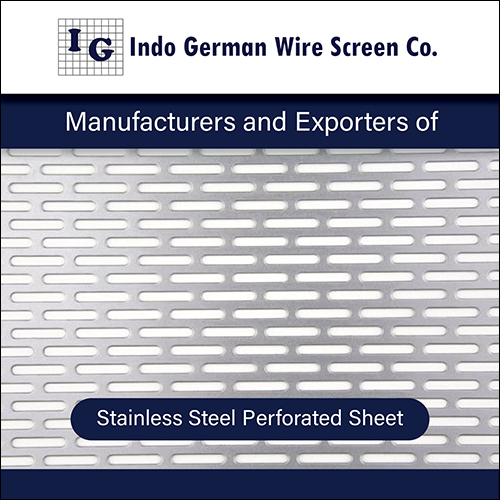

Stainless Steel Perforated Sheet

Price Range 100.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Stainless Steel

Product Type : Perforated Sheet

Usage : industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry