Perforated Metal Screen

Price 1000 INR/ Foot

Perforated Metal Screen Specification

- Usage

- industrial

- Material

- Metal

- Size

- 0.1-2 mm

- Product Type

- Perforated Metal Screen

- Color

- Steel

- Thickness

- 2 Millimeter (mm)

Perforated Metal Screen Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Perforated Metal Screen

Perforated Metal Screenor perforated metal sheets is made through metal punching processes for high filterability with superior weight reduction.Features of Perforated Sheets:

- Perfect filterability

- Protective function

- Sunlight and radiation containment

- Heat dissipation

Product details

|

Technique |

Perforated |

|

Country of Origin |

Made in India |

|

Material |

Metal |

|

I Deal In |

New Only |

|

Brand |

Indo German |

|

Usage |

Industrial |

|

Usage/Application |

Industrial |

|

Hole Size |

0.1-2 mm |

|

Thickness |

Up to 2 mm |

|

Usage/Applications |

Automotive,Construction,Pharma Industry,Fencing,Food Industry,Agricultural,Textile Industry,Architectur |

Superior Industrial Performance

Our perforated metal screens are crafted to withstand demanding industrial environments. Suitable for filtration, screening, and protection, they provide reliable efficiency with minimal maintenance. Their precise perforation ensures consistent results, making them a favored choice in manufacturing plants.

Quality Assurance and Versatility

We maintain rigorous quality standards across production as exporters, suppliers, and manufacturers in India. The screens are available in steel color and various sizes, catering to distinct industrial requirements. Each screen undergoes thorough inspection for strength and uniformity before delivery.

FAQs of Perforated Metal Screen:

Q: How is the perforated metal screen produced for industrial applications?

A: The perforated metal screen is manufactured by punching or laser cutting precise holes (0.1-2 mm) into durable metal sheets, typically with a thickness of 2 mm. This process ensures consistent quality and creates an ideal structure for industrial usage such as filtration, separation, and protection.Q: What are the typical uses of these perforated metal screens in industrial settings?

A: Industrial perforated metal screens are commonly used for filtering liquids or air, screening solid particles, ventilation panels, and protective barriers. Their robust design and small hole sizes make them suitable for demanding applications in manufacturing, chemical processing, and material handling.Q: When should I choose a steel-colored perforated metal screen with 2 mm thickness?

A: A steel-colored perforated metal screen with 2 mm thickness is preferred when durability, corrosion resistance, and mechanical strength are required. It is ideal for harsh industrial environments where longevity and structural integrity are crucial, such as factories and processing plants.Q: Where are these perforated metal screens commonly installed in an industrial facility?

A: Perforated metal screens can be installed in machinery guards, air ventilation systems, sieving equipment, and partitions within industrial facilities. Their versatility allows them to be integrated wherever efficient filtering, separation, or protective screening is necessary.Q: What is the process for sourcing perforated metal screens from your company in India?

A: As a leading exporter, manufacturer, supplier, and trader, we streamline the procurement process. Clients can contact us with specific requirements, and we provide tailored solutions, including customization of size, thickness, and perforation pattern. Quality checks and prompt delivery are always ensured.Q: How does using perforated metal screens benefit industrial operations?

A: Utilizing perforated metal screens enhances operational efficiency by improving filtration, reducing maintenance, and ensuring safety. Their robust build minimizes downtime, while precise perforations allow for optimal separation or ventilation, ultimately saving costs and maintaining productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

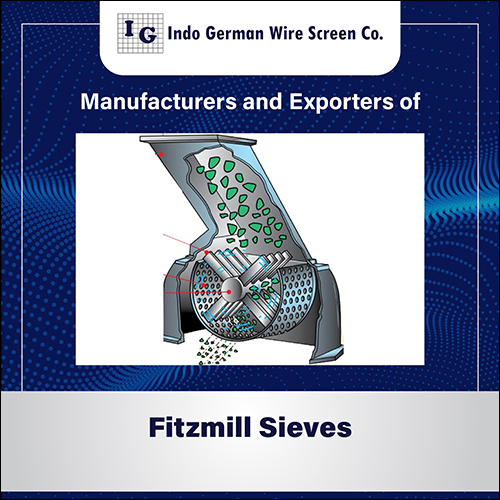

Fitzmill Sieves

Price 1000 INR / Foot

Minimum Order Quantity : 10

Product Type : Fitzmill Sieves

Material : Stainless Steel

Usage : industrial

Shape : Round or Custom shapes

Perforated Metal Screens

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Perforated Metal Screens

Material : Stainless Steel Wire

Usage : industrial

Shape : Circular

Punching Hole Mesh

Price 120 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Material : Steel

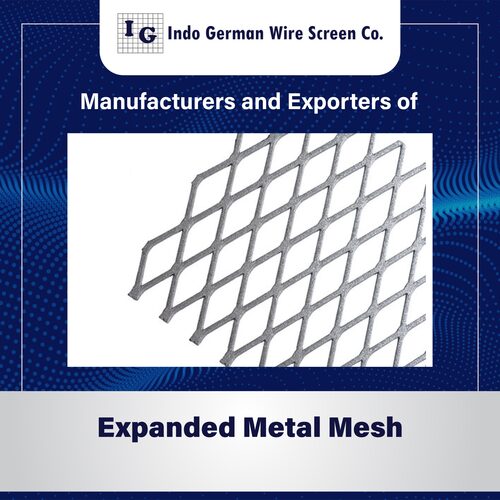

Expanded Metal Sheets

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Expanded Metal Sheets

Material : Stainless Steel Wire

Usage : industrial

Shape : Diamond

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry