Sifter Sieves For Vibro Screen

Price 1000 INR/ Foot

Sifter Sieves For Vibro Screen Specification

- Surface Treatment

- Polished / Smooth Finish

- Standard

- ISO 9001:2015

- Shape

- Round

- Temper

- Annealed / Hardened (as per requirement)

- Process

- Precision welding and wire mesh fabrication

- Usage

- industrial

- Material

- Stainless Steel

- Type

- Sifter Sieves

- Technique

- Perforated/ Woven mesh fabrication

- Product Type

- Sifter Sieves For Vibro Screen

- Color

- Steel

- Thickness

- 0.5 mm to 2 mm (customizable)

- Application

- Screening, Grading, Sifting, Filtering in food, pharmaceutical, chemical and mining industries

- Feature

- High durability, Precise mesh opening, Corrosion resistant

- Diameter

- 12" to 60" (various sizes available)

- Edge Finishing

- Epoxy Bonded/Rubber Gasket/Metal Bound

- Opening Size

- As per client specification

- Installation

- Simple and hassle-free fitment

- Cleaning Method

- Easy to clean, washable and reusable

- Load Capacity

- Heavy Duty, supports high throughput

- Fitment

- Compatible with most Vibro Screens and Sifters

- Mesh Size

- 10 mesh to 400 mesh (customizable as per application)

Sifter Sieves For Vibro Screen Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Sifter Sieves For Vibro Screen

Vibro Sifter Sieves usually use vibration energy or a combination of Vibration & ultrasonic energies to achieve screening. Sieves have to be specially designed to resist the high tensile stress generated. Since Particle Size Distribution plays a vital part in drug dissolution, maintaining the accuracy of the sieve apertures is an essential part of sieve manufacturing. The proper thickness of wire, accurate nominal aperture sizes, high tensile strength & tautness of the sieve are essential for high sifting performance.

Product details

|

Country of Origin |

Made in India |

|

Material |

SS |

|

Customisation |

Customised |

|

Shape |

Round |

|

Model Name/Number |

Sifter Sieves For Vibro Screen |

Precision Mesh Fabrication for Versatile Screening

Engineered with advanced perforated and woven mesh techniques, these sifter sieves ensure precise and consistent mesh openings tailored to your specific needs. The polished or smooth finish and annealed or hardened temper options guarantee reliability and performance for heavy-duty industrial usage.

Customizable Dimensions for Diverse Applications

With mesh sizes from 10 mesh to 400 mesh and diameters from 12 to 60 inches, you can select the exact specifications required for your process. Openings are designed as per your application, allowing for optimal grading, sifting, filtering, or screening in multiple industries.

Effortless Cleaning and Installation

Each sieve is washable and reusable, simplifying maintenance without compromising screening efficiency. The simple fitment design makes installation hassle-free, reducing downtime and increasing productivity in your operations.

FAQs of Sifter Sieves For Vibro Screen:

Q: How do I choose the appropriate mesh size and diameter for my Vibro Screen application?

A: Select the mesh size and diameter based on the desired level of filtration, material type, and throughput requirements. Mesh sizes range from 10 to 400, while diameters span from 12" to 60", allowing customization to fit your process specifications.Q: What are the available edge finishing options and how do they affect compatibility with different Vibro Screens?

A: The sieves offer epoxy bonded, rubber gasket, and metal bound edge finishing. These options provide secure fitment, enhance durability, and ensure compatibility with a wide variety of Vibro Screens and Sifters in industrial setups.Q: Where can these sifter sieves be used within industrial processes?

A: These sieves are suitable for screening, grading, sifting, and filtering applications in food, pharmaceutical, chemical, and mining industries, catering to both large-scale production and laboratory operations.Q: What is the installation process for these sifter sieves?

A: Installation is straightforward; the sieves are engineered for simple and hassle-free fitment, making them compatible with most Vibro Screens. No specialized tools are required, supporting quick changeovers and routine maintenance.Q: How are the sieves manufactured to ensure precise mesh openings and durability?

A: Manufacturing involves precision welding, wire mesh fabrication, and perforation using stainless steel, followed by surface treatment such as polishing or smooth finishing. Each sieve conforms to ISO 9001:2015 standards, ensuring quality and reliability.Q: What methods can be used to clean and maintain these sifter sieves?

A: The sieves are designed to be easy to clean, washable, and reusable. Standard cleaning methods include rinsing, brushing, and using mild detergents. This allows for frequent reuse without loss of performance, preserving efficiency and hygiene.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Granules

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Material : Stainless Steel

Usage : industrial

Product Type : Sifter Sieves

Thickness : Customizable (commonly 0.5mm to 1.0mm)

Perforated Metal Screen

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Material : Metal

Usage : industrial

Product Type : Perforated Metal Screen

Thickness : 2 Millimeter (mm)

Perforated Metal Sheets

Price 10 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Stainless Steel Wire

Usage : industrial

Product Type : Perforated Metal Sheets

Thickness : 0.25 5 Millimeter (mm)

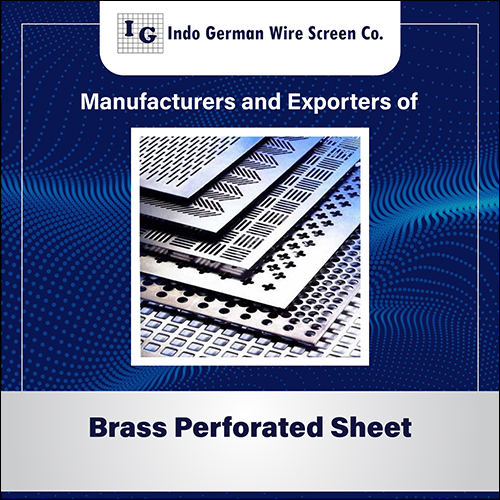

Brass Perforated Sheet IGWS75

Minimum Order Quantity : 10 Square Foots

Material : Other

Usage : industrial

Product Type : Brass Perforated Sheet

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry