Stainless Steel Welded Woven Wire Mesh

Price 50 INR/ Unit

Stainless Steel Welded Woven Wire Mesh Specification

- Aperture

- 6 mm to 50 mm

- Wire Gauge

- 14 Gauge to 22 Gauge

- Length

- 15 m, 30 m (custom lengths available)

- Surface Treatment

- Galvanized, Annealed, Polished

- Hole Shape

- Square

- Product Type

- Welded Woven Wire Mesh

- Mesh Type

- Wire Mesh

- Mesh Style

- Welded, Woven

- Material

- Stainless Steel (Grade 304, 316, 316L)

- Alloy

- Stainless Steel 304, 316, 316L

- Application

- Fencing, Filtration, Construction, Industrial & Agricultural Uses

- Dimensions

- As per requirement; standard width: 0.6 m to 2.5 m

- Wire Diameter

- 0.7 mm to 2.03 mm

- Weight

- Varies with dimensions and wire gauge

- Color

- Silver

- Tensile Strength

- High tensile strength for structural integrity

- Custom Sizes

- Custom mesh count, aperture, and width can be manufactured on request

- Packing

- Rolls wrapped with waterproof paper, or as per customer requirement

- Edge Type

- Cut or folded edges available

- Corrosion Resistance

- Excellent, suitable for outdoor and harsh environments

- Max Operating Temperature

- Up to 800°C for SS316

- Usage Environment

- Indoor and outdoor

- Export Markets

- Global shipping available

- Certificates

- ISO 9001:2015 compliant, RoHS certified

About Stainless Steel Welded Woven Wire Mesh

Stainless Steel Welded Woven Wire Mesh or wire cloth is technically a wire mesh panel accurately manufactured by, woven to size in the same technique cloth is woven, manufactured on a loom. It is particularly useful because it works perfectly with hot or cold liquids, is extremely chemical resistant, and can be easily cleaned. Stainless Steel Welded Woven Wire netting is normally woven on looms, like looms that are normally used to weave cloth. Usually, any specification that is 5 x 5 Mesh and finer is a woven wire mesh. Stainless Steel Welded Woven Wire Meshes are exceptionally multipurpose and adaptable and easy to install, and are used in numerous applications. Heavier Stainless Steel Welded Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Stainless Steel Welded Woven Wire mesh is ideal for both industrial & architectural applications.Engineered for Versatility and Durability

Designed for industrial, agricultural, construction, filtration, and fencing applications, our welded woven wire mesh provides unparalleled strength and corrosion resistance. With options for cut or folded edges, several surface finishes, and custom sizing, it seamlessly adapts to diverse project specifications for worldwide clients.

Premium Materials and Certifications

Manufactured from stainless steel grades 304, 316, and 316L, our wire mesh combines longevity with superior performance even in harsh environments. Compliance with ISO 9001:2015 and RoHS certification guarantees quality, safety, and eco-friendly standards for every mesh supplied.

FAQs of Stainless Steel Welded Woven Wire Mesh:

Q: How can I request custom sizes and specifications for the stainless steel wire mesh?

A: Custom mesh count, aperture, width, and length can be manufactured to order. Simply provide your requirements for dimensions, wire gauge, and hole shape, and we will tailor the mesh to fit your application.Q: What are the typical usage environments for this wire mesh?

A: This wire mesh is suitable for both indoor and outdoor settings, including exposure to harsh and corrosive environments, thanks to its excellent corrosion resistance and durable construction.Q: When should I choose between cut and folded edge types?

A: Select cut edges for straightforward installations where the mesh will be framed or fixed directly. Folded edges are ideal when enhanced safety, improved aesthetics, or additional rigidity is required at the border.Q: What is the process for ensuring quality and compliance?

A: Every mesh is manufactured following stringent ISO 9001:2015 standards and is RoHS certified. Each product undergoes quality checks for tensile strength, corrosion resistance, and dimensional accuracy.Q: Where do you ship your stainless steel wire mesh products?

A: We offer global shipping, exporting our wire mesh to markets worldwide. Packaging can be customized with waterproof paper wrapping or according to specific customer requirements.Q: How does high tensile strength benefit structural applications?

A: High tensile strength ensures superior structural integrity, making the wire mesh reliable for load-bearing and reinforcement applications in construction, industrial processes, and fencing.Q: What are the available surface treatments and finishes for your wire mesh?

A: Our meshes are available in galvanized, annealed, or polished finishes, allowing you to choose the most appropriate treatment for aesthetic appeal, additional protection, or specific industrial purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

Inconel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Mesh Type : Other , Plain Weave / Twill Weave

Application : Other

Mesh Style : Woven Mesh

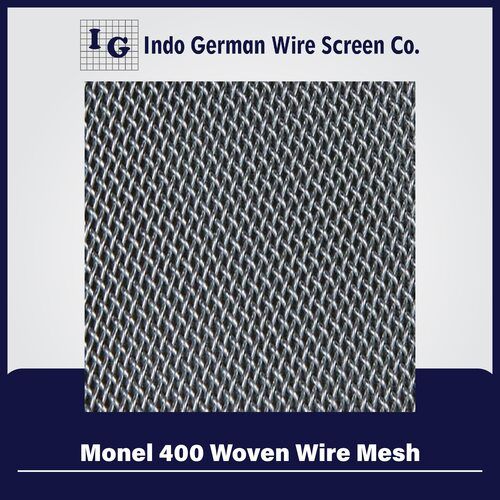

Monel 400 Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Mesh Type : Other , Monel 400 Woven Wire Mesh

Application : Other

Mesh Style : Woven Mesh

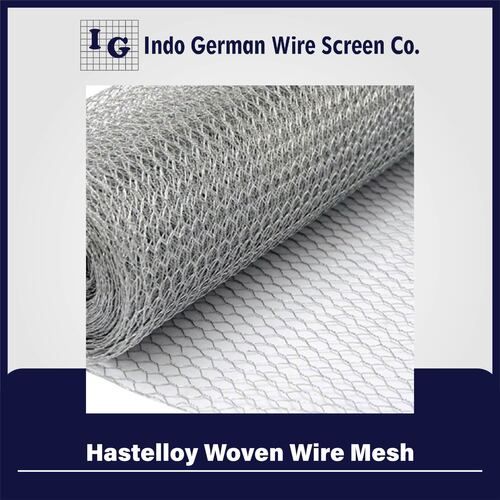

Hastelloy Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Mesh Type : Other , Fine Mesh / Crimped Mesh (optional)

Application : Other

Mesh Style : Woven Mesh

Tungsten Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Uncoated

Mesh Type : Other , Woven

Application : Other, Filtration, Sieving, Electronics, Aerospace, Medical, Chemical processing

Mesh Style : Other , Plain weave, Twilled weave

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry