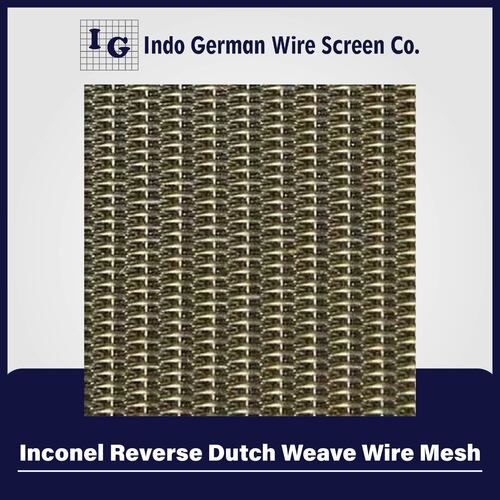

Inconel Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Inconel Reverse Dutch Weave Wire Mesh Specification

- Length

- up to 30 meters (customizable)

- Wire Gauge

- 0.5 mm to 6 mm

- Aperture

- 10100 microns (customizable)

- Surface Treatment

- Coated

- Hole Shape

- Rectangular (Reverse Dutch Weave)

- Product Type

- Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Inconel 600/625/800

- Application

- Other

- Dimensions

- Custom sizes available; standard width up to 2 meters

- Wire Diameter

- 0.5 mm 6 mm

- Weight

- Varies with size and wire diameter; approx. 315 kg/m

- Color

- Silver

- Operating Temperature Range

- up to 1000C

- Corrosion Resistance

- Excellent, suitable for harsh environments

- Edge Type

- Plain/Finished edges

- Open Area Percentage

- 5% 50% depending on weave

- Packaging Type

- Rolls, Wooden Cases

- Acid Resistance

- Strong resistance to acids and alkalis

- Tensile Strength

- High

- Roll Length

- up to 30 meters

- Usage

- Filtration, chemical processing, petrochemical, aerospace, high-temperature applications

Inconel Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Reverse Dutch Weave Wire Mesh

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added in to Inconel as per requirement and grade. Inconel are useful in wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.Inconel Reverse Dutch Weave Wire Meshis manufactured with smaller warp wires that are more numerous than the weft wires. Smaller and closer wrap wires together with the weft wires form triangular shaped transversal openings. The same weave as Plain Dutch except the warp and Shute wires are reversed; i.e., the warp wires have a smaller diameter than the Shute wires.We offer an exclusive range ofInconel Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Superior Performance in Extreme Conditions

Inconel Reverse Dutch Weave Wire Mesh is designed to withstand rigorous operating environments. Its construction from Inconel alloys guarantees resilience against extreme temperatures and corrosive mediums, making it ideal for aerospace, filtration, and chemical processing. Whether exposed to acids, alkalis, or high heat, the mesh maintains its structural integrity and filtration efficiency.

Customizable Filtration Solutions

With customizable dimensions, aperture sizes, and wire diameters, this mesh offers flexibility for specific application requirements. Its open area percentage ranges from 5% to 50%, supporting precise control over flow and separation processes. The variety in roll lengths and edge treatments ensures suited installations for unique project needs.

Reliable Quality from Indian Manufacturers

Produced by leading Indian exporters, manufacturers, and suppliers, this mesh adheres to stringent quality standards. Each product undergoes specialized surface coating and inspection to ensure superior performance, consistent delivery, and reliable operation in harsh environments. Bulk and custom orders are efficiently packaged in rolls or wooden cases for safe transport and handling.

FAQs of Inconel Reverse Dutch Weave Wire Mesh:

Q: How does Inconel Reverse Dutch Weave Wire Mesh handle high temperatures during operation?

A: Thanks to its construction from Inconel alloys (600/625/800), the mesh offers stable performance up to 1000C. This makes it ideal for applications involving extreme heat, such as aerospace and high-temperature filtration.Q: What benefits does the Reverse Dutch Weave style provide for filtration applications?

A: The Reverse Dutch Weave design enhances mechanical strength and enables efficient separation, allowing for tailored aperture sizes (10100 microns) and varying open area percentages. It supports fine particle retention while sustaining high flow rates.Q: When is it recommended to use Inconel wire mesh in industrial processes?

A: Inconel wire mesh is ideal when working in corrosive or high-temperature environmentssuch as chemical processing, petrochemical plants, or aerospacewhere strength, acid resistance, and durability are crucial for reliable operations.Q: Where can this mesh be installed and utilized effectively?

A: It is suitable for integration in filtration systems, chemical reactors, aerospace equipment, and any setting where harsh environmental factors and precise separation or filtration are required.Q: What surface treatments are applied for enhanced durability?

A: The mesh undergoes specialized coating processes to improve resistance to oxidation and environmental wear, extending its operational lifespan in aggressive chemical and thermal contexts.Q: How is the wire mesh typically packaged and shipped?

A: Depending on order size and requirements, the mesh is packaged in rolls or sturdy wooden cases to protect it against handling damage during transport, with roll lengths up to 30 meters available.Q: What is the process for customizing mesh dimensions or aperture sizes?

A: Customers can specify desired widths, lengths (up to 30 meters), wire diameters (0.56 mm), and aperture sizes to meet their unique filtration or separation needs. Manufacturers in India accommodate such custom orders with precision engineering.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

Nickel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Silver

Application : Other, Filtration, Chemical Processing, Battery Electrode, Gas and Liquid Separation

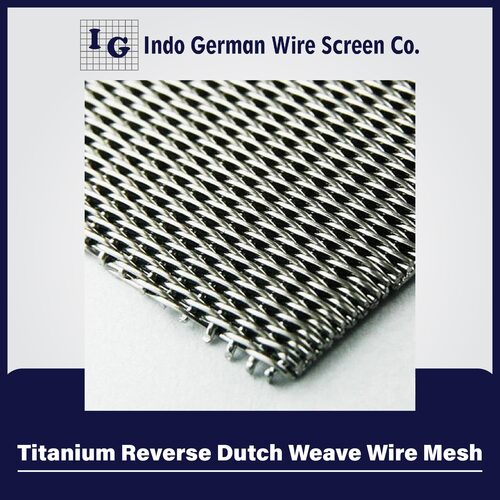

Titanium Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Silver

Application : Other

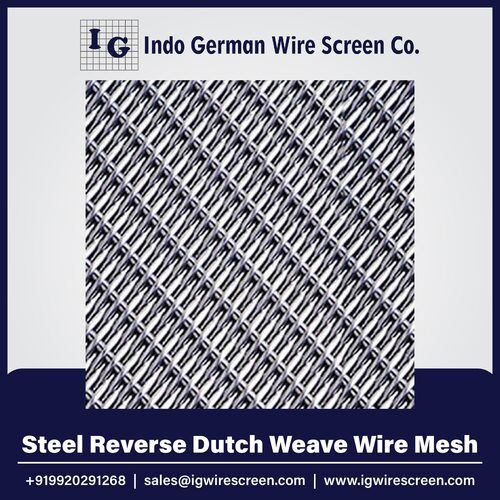

Steel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Silver

Application : Other

Copper Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Copper

Application : Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry