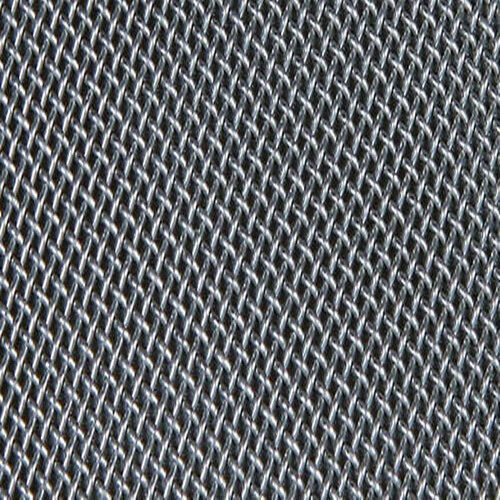

Titanium Fine Wire Mesh

Price 50 INR/ Unit

Titanium Fine Wire Mesh Specification

- Length

- 30 Meter Roll

- Wire Gauge

- 24 SWG

- Hole Shape

- Square

- Surface Treatment

- Polished

- Aperture

- 0.3 mm

- Product Type

- Fine Wire Mesh

- Mesh Type

- Plain Weave

- Mesh Style

- Woven

- Material

- Titanium

- Alloy

- Grade 2 (Commercially Pure Titanium)

- Application

- Filtration, Chemical Processing, Aerospace, Medical

- Dimensions

- 1 Meter Width

- Wire Diameter

- 0.2 mm

- Weight

- Approx. 2.5 kg/Roll

- Color

- Metallic Gray

- Standards

- ASTM B348

- Corrosion Resistance

- Excellent (Acids, Alkalis, Chlorides)

- Tensile Strength

- Min. 345 MPa

- Open Area Percentage

- 28%

- Packing Type

- Bubble wrap + Carton

- Service Life

- Long-lasting, over 10 years (normal conditions)

- Customization

- Available (length, width, mesh size)

- Temperature Resistance

- Up to 600°C

About Titanium Fine Wire Mesh

Titanium Fine Wire Mesh or Fine Wire cloth is a welded wire mesh panel specifically manufactured by welding thin and thick diameter wires to form a Fine Wire Netting. Plain weave is the commonly used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter. Fine Wire Mesh is a mesh of wires combined together having fine holes on its surface. Titanium Fine Wire mesh or wire cloth is thin woven wire meshes with mesh from 11 to 500 500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch).

Titanium Fine Wire netting can have aperture from 0.0254 mm to 23.37 mm (0.001 inch to 0.92 inch) and when the wire diameter becomes thinner the aperture will be larger.

Exceptional Durability and Chemical Resistance

With a minimum tensile strength of 345 MPa and superior resistance to corrosive agentsincluding acids, alkalis, and chloridesthis titanium fine wire mesh ensures long-lasting performance exceeding 10 years under normal conditions. Its resilience at temperatures up to 600C and polished surface guarantee reliability for rigorous industrial use.

Tailored Solutions for Specialized Applications

The mesh can be fully customized in length, width, and mesh size to meet unique project needs. Its versatile design, including various mesh and hole shapes, supports a wide range of uses in filtration, chemical processing, aerospace, and medical sectors, making it ideal for projects requiring precision and robustness.

FAQs of Titanium Fine Wire Mesh:

Q: How is the titanium fine wire mesh typically used in industrial applications?

A: This wire mesh is widely used for filtration, chemical processing, aerospace, and medical applications due to its excellent corrosion resistance, high tensile strength, and temperature durability. Its design allows precise filtering of particles, making it ideal in environments requiring stringent quality control.Q: What benefits does the 28% open area and 0.3 mm aperture provide?

A: A 28% open area with a 0.3 mm square aperture offers an optimal balance between airflow or fluid passage and particle filtration. This configuration ensures effective filtering performance while maintaining system efficiency and minimal clogging.Q: When should I choose Grade 2 titanium mesh over other metals?

A: Grade 2 titanium mesh is recommended when superior corrosion resistance, biocompatibility, and high temperature tolerance are required. Its preferred in sectors like medical, chemical processing, and aerospace, where exposure to harsh chemicals or high heat would challenge other metal meshes.Q: Where is this wire mesh manufactured and exported from?

A: This titanium fine wire mesh is manufactured and supplied by reputable exporters, manufacturers, suppliers, and traders based in India, serving both domestic and international markets according to ASTM B348 standards.Q: What is the process for customizing the mesh dimensions or properties?

A: Customization options include altering length, width, mesh size, and aperturesimply specify your requirements to the supplier during the order process. This ensures suitability for specialized applications and seamless integration into your system.Q: How should the mesh be stored and shipped to maintain its integrity?

A: The mesh is securely packed in bubble wrap and cartons to prevent physical damage during transportation. It should be stored in a dry, clean environment to maintain its polished surface and prolong its functional lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, catalyst support, high temperature screening, precision electronics

Mesh Style : Other , Woven

Product Type : Other, Fine Wire Mesh

Color : Silvergrey

Aluminium Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, sieving, insect screens, ventilation

Mesh Style : Other , Woven

Product Type : Other, Fine Wire Mesh

Color : Silver

Monel 400 Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Chemical Processing, Marine, Aerospace, Oil & Gas

Mesh Style : Woven Mesh

Product Type : Other, Fine Wire Mesh

Color : Metallic Grey

Mild Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Screening, Industrial Use, Construction

Mesh Style : Woven Mesh

Product Type : Wire Mesh

Color : Metallic Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry