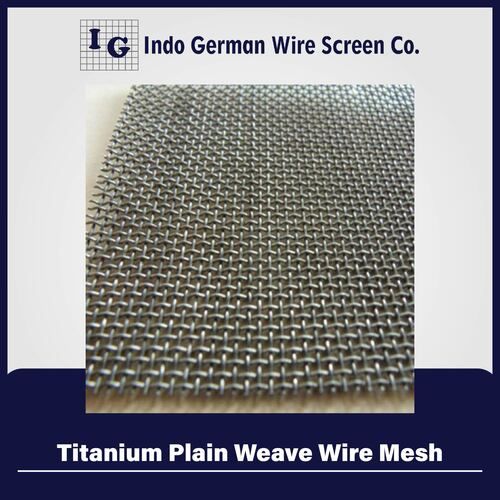

Titanium Plain Weave Wire Mesh

Price 50 INR/ Unit

Titanium Plain Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Dutch Weave Wire Mesh

- Material

- Titanium

- Application

- Other

- Color

- Gray

Titanium Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Titanium Plain Weave Wire Mesh

Titanium is known for its high durability, light weight, high strength, and corrosion-resistant properties. The Titanium metal is resistant to saltwater, metallic salts, hydroxides, chromic acids, chlorides, nitric acids, organic acids, and dilute alkalis. Titanium Wire Mesh is available in black colour, with diverse weaving patterns of plain and twill weave.Warp wire- It runs in the direction of mesh length.Each weft wire goes alternatively over and under each warp wire, and vice versa.Titanium Plain Weave Wire Meshesare available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh). Its easily cleanable with identical apertures andCan be easily cut and shaped, and quick to unroll & install.

Versatile Mesh Styles for Varied Applications

Choose between plain weave and Dutch weave mesh styles to suit an array of filtration and screening needs. Titaniums unique attributes, coupled with advanced weaving techniques, result in products tailored to challenging environments, particularly where resistance to chemicals and high temperatures is essential.

Reliable Titanium Mesh Solutions from India

As a reputable supplier and exporter in India, we ensure each mesh undergoes precise coating and quality control. Our mesh offerings cater to industries such as chemical processing, aerospace, marine, and pharmaceuticals, where performance and reliability are paramount.

FAQs of Titanium Plain Weave Wire Mesh:

Q: How is titanium wire mesh with a Dutch weave different from plain weave?

A: The Dutch weave style incorporates a mix of finer warp and thicker weft wires, creating a tight, durable structure ideal for fine filtration. In contrast, the plain weave mesh uses uniform wires crossing alternately, suitable for general screening and larger particle retention.Q: What are the surface treatment and color benefits of this coated gray titanium mesh?

A: The applied coating enhances the meshs resistance to oxidation and corrosion, making it more suitable for use in aggressive and high-moisture environments. The gray color is the natural look of titanium, providing a sophisticated appearance while maintaining material integrity.Q: Where can titanium wire mesh be applied in industrial sectors?

A: Titanium wire mesh finds use in industries like chemical processing, marine engineering, filtration, aerospace, and pharmaceuticals due to its exceptional chemical resistance, anti-corrosive properties, and mechanical stability even under harsh conditions.Q: What is the production process for titanium coated wire mesh?

A: High-purity titanium wires are carefully woven using plain or Dutch weave patterns, then subjected to specialized coating processes. This ensures uniformity, optimal protection, and extended service life, adhering to stringent industry standards.Q: How does the use of titanium mesh benefit filtration processes?

A: Titanium mesh offers superior corrosion resistance, lightweight strength, and longevity, minimizing maintenance needs and downtime. These benefits facilitate efficient and reliable filtration, especially in demanding chemical or marine applications.Q: When should you choose Dutch weave over other mesh styles for your project?

A: Dutch weave is preferred when ultra-fine filtration or high mechanical strength is necessary, such as in liquid filtration systems or protective screening, whereas plain weave suffices for less intensive screening tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

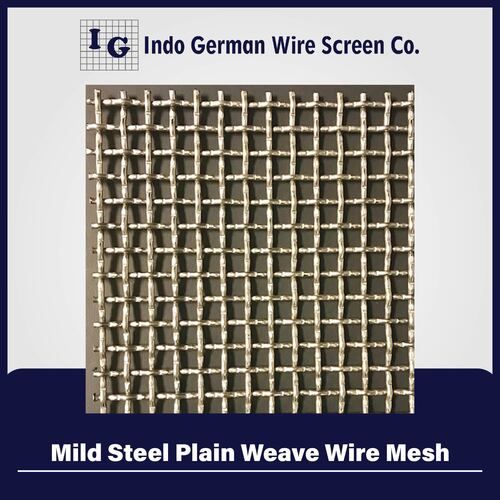

Mild Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Gauge : 10 to 30 SWG

Length : 30 meters (standard roll), can be customized

Wire Diameter : 0.3 mm to 3 mm

Hole Shape : Other , Square

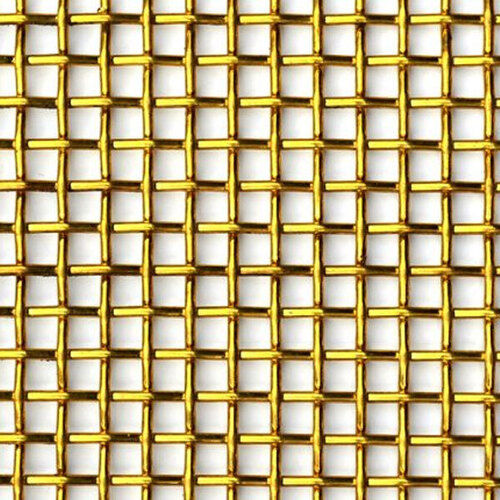

Brass Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Gauge : 8100 SWG (can be customized)

Length : 30 meters or as required

Wire Diameter : 0.12 mm to 2.0 mm

Hole Shape : Other , Square

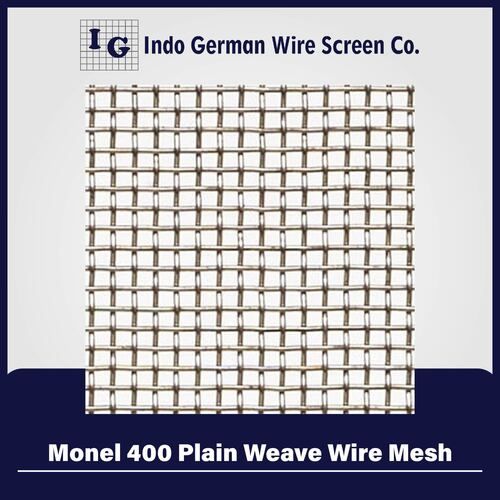

Monel 400 Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Gauge : Standard or Custom

Length : Customizable

Wire Diameter : Customizable

Hole Shape : Other , Square

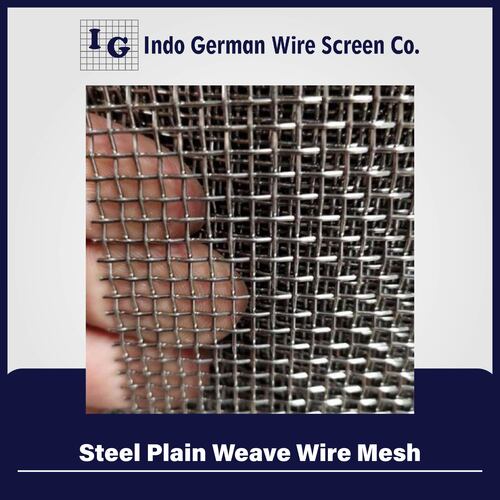

Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Gauge : 18 SWG

Length : 30 meter (standard roll)

Wire Diameter : 1.2 mm

Hole Shape : Other , Square

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry