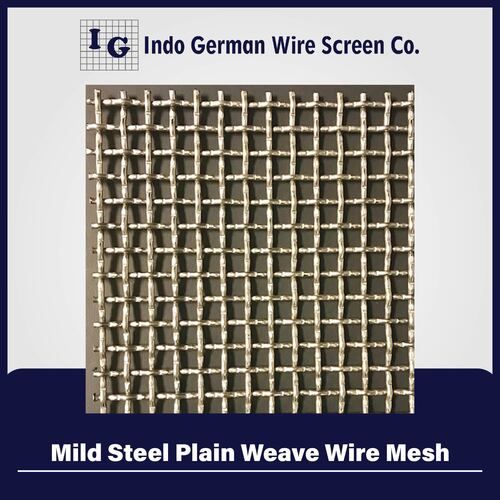

Mild Steel Plain Weave Wire Mesh

Price 50 INR/ Unit

Mild Steel Plain Weave Wire Mesh Specification

- Length

- 30 meters (standard roll), can be customized

- Surface Treatment

- Coated

- Wire Gauge

- 10 to 30 SWG

- Hole Shape

- Square

- Aperture

- 0.5 mm to 20 mm

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave

- Mesh Style

- Plain Mesh

- Material

- Mild Steel

- Alloy

- Low Carbon Steel

- Application

- Other

- Dimensions

- Width 1 meter to 2 meters

- Wire Diameter

- 0.3 mm to 3 mm

- Weight

- Depends on mesh spec, approx. 40 kg to 100 kg per roll

- Color

- Gray

- Temper

- Soft/Annealed

- Service Life

- 5+ years (under normal conditions)

- Edge Type

- Cut or Selvedge

- Tensile Strength

- 350-550 MPa

- Packaging Type

- Rolls, Wooden Cases

- Open Area

- 35-80% depending on mesh

- Usage

- Fencing, Filtration, Construction, Screening

- Resistance

- Corrosion Resistant (post-coating)

Mild Steel Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Mild Steel Plain Weave Wire Mesh

Warp wire- It runs in the direction of mesh length.Each weft wire goes alternately over and under each warp wire, and vice versa. Usually the finerMild Steel Plain Weave Wire Meshweaves are most commonly used in petrochemical and food processing, chemical, plastic production houses, on the other hand, coarserMild Steel Plain Weave Wire Meshweaves are used for dewatering, sizing, filter cloth and extruding applications.Mild Steel Plain Weave Wire Meshesare available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh).

Versatile Applications

Mild Steel Plain Weave Wire Mesh is utilized across multiple industries due to its strength and flexibility. Its primary uses include fencing, material filtration, construction reinforcement, and screening. The customizable mesh openings and various wire gauges make it suitable for both fine and coarse requirements, ensuring compatibility with diverse operational needs.

Durability and Longevity

This wire mesh stands out for its corrosion resistance, achieved through specialized post-coating treatments. Under recommended conditions, the mesh provides a service life of over five years, making it a cost-effective solution. Its robust construction ensures that it maintains integrity even in challenging environments, ideal for both indoor and outdoor applications.

Customizable Specifications

Clients can select from a wide range of customizable options, including mesh aperture (0.5 mm to 20 mm), wire gauge (10 to 30 SWG), roll width (1 to 2 meters), and edge types (cut or selvedge). This ensures the mesh can be tailored to suit specific project requirements, with packaging options like rolls and wooden cases for secure delivery.

FAQs of Mild Steel Plain Weave Wire Mesh:

Q: How is the Mild Steel Plain Weave Wire Mesh manufactured?

A: The mesh is produced using soft or annealed low carbon steel wires, woven in a plain weave style to create precise apertures ranging from 0.5 mm to 20 mm. After weaving, the mesh undergoes a surface coating process to enhance corrosion resistance, ensuring durability in varied environments.Q: What are the main benefits of using this wire mesh?

A: Key advantages include its customizable design, excellent corrosion resistance (post-coating), high tensile strength, and long service life. Its adaptability makes it suitable for fencing, filtration, construction, and screening, offering reliable performance in demanding conditions.Q: Where can the Mild Steel Plain Weave Wire Mesh be applied?

A: This mesh is ideal for use in fencing systems, building construction, material screening and classification, and filtration installations. Its varying aperture and wire gauge options accommodate different industrial, commercial, and agricultural applications.Q: When should I choose a plain weave mesh over other mesh styles?

A: Plain weave mesh is preferred when uniformity, strength, and consistency are required. It is especially effective for filtration and screening tasks and is easier to handle during installation, making it a practical choice for general-purpose applications.Q: What is the typical service life of this wire mesh and how is it maintained?

A: With proper post-coating surface treatment, the wire mesh offers a service life of over five years under normal operating conditions. Regular inspections for physical damage and occasional cleaning help maintain its longevity and performance.Q: How is the mesh packaged for export and delivery?

A: Packaging options include tightly wound rolls and durable wooden cases, ensuring the mesh remains intact and undamaged during domestic and international transit. Packaging can be customized based on client requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

Nichrome A Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

Application : Other

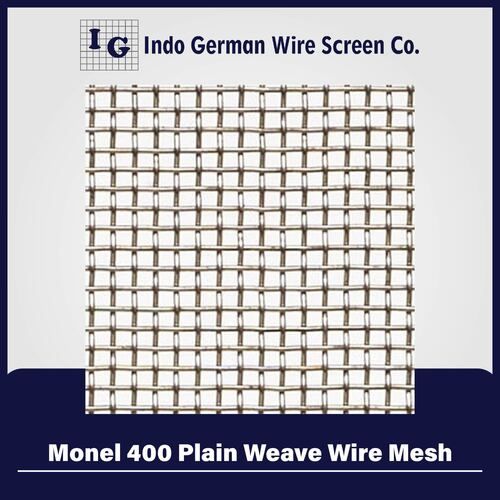

Monel 400 Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic

Surface Treatment : Other, As Required

Product Type : Wire Mesh

Application : Other, Industrial Screening Filtration Separation

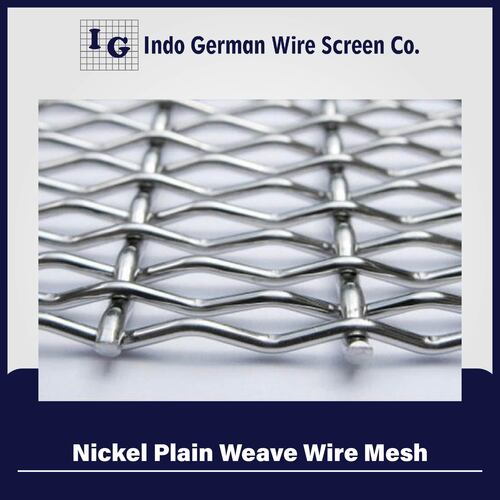

Nickel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

Application : Other

Hastelloy Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic Silver

Surface Treatment : Other, Polished / Uncoated

Product Type : Other, Plain Weave Wire Mesh

Application : Other, Filtration, Oil & Gas, Chemical Processing, Petrochemicals, Aerospace, Marine, Environmental, Food Processing

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry