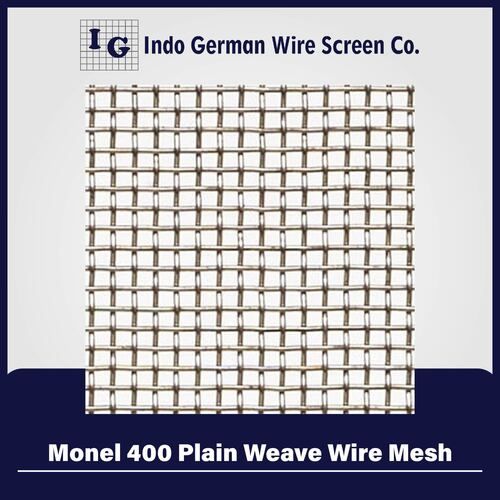

Monel 400 Plain Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Monel 400 Plain Weave Wire Mesh Specification

- Surface Treatment

- As Required

- Hole Shape

- Square

- Wire Gauge

- Standard or Custom

- Length

- Customizable

- Aperture

- Plain Weave

- Product Type

- Wire Mesh

- Mesh Type

- Wire Mesh

- Mesh Style

- Plain Weave

- Material

- Monel Alloy

- Alloy

- Monel 400

- Application

- Industrial Screening Filtration Separation

- Dimensions

- Customizable

- Wire Diameter

- Customizable

- Weight

- Variable Based on Dimensions

- Color

- Metallic

Monel 400 Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Monel 400 Plain Weave Wire Mesh

Monel 400 is a combination of nickel and copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% and is versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments. Compared to the common stainless steel wire mesh, monel wire mesh has a high melting point of 1300 F to 1350 F and strength superior to unalloyed nickel. Due to this exceptional quality, monel wire mesh is being used inside high-temperature vessels and petroleum applications.Exceptional Chemical and Corrosion Resistance

Monel 400 wire mesh stands out for its superior resistance to chemicals, including acids and alkalis. This property makes it ideal for harsh industrial settings where corrosion can be a major concern. Suitable for chemical processing plants, the wire mesh maintains integrity and strength even in aggressive environments, maximizing the longevity of your filtration or separation systems.

Versatile Applications in Filtration and Separation

With its customizable dimensions, wire gauge, and mesh style, Monel 400 wire mesh is engineered for industrial screening, filtration, and separation tasks. From water treatment facilities to oil refineries, its adaptable construction fits a diverse range of filtration units, sieves, and separators, optimizing operational efficiency across multiple industries.

FAQs of Monel 400 Plain Weave Wire Mesh:

Q: How is Monel 400 Plain Weave Wire Mesh used in industrial applications?

A: Monel 400 Plain Weave Wire Mesh is widely utilized in industrial screening, filtration, and separation processes. Its resistance to corrosion makes it suitable for chemical, petrochemical, and marine environments, ensuring reliable performance and minimal maintenance.Q: What are the benefits of choosing Monel 400 alloy for wire mesh?

A: The primary benefits of Monel 400 alloy include exceptional durability, corrosion resistance, and a long service life. It withstands aggressive chemicals and high temperatures, providing effective performance in tough industrial applications where standard stainless steel may not suffice.Q: When should a plain weave mesh style be selected over other types?

A: The plain weave mesh style is ideal when uniform aperture size and consistent flow rates are needed. This style provides stable filtration and is commonly selected for applications requiring precise screening, such as fine filtration or grading of materials.Q: Where can Monel 400 Plain Weave Wire Mesh be applied?

A: This wire mesh is suitable for a variety of locations, including chemical plants, water treatment facilities, oil and gas installations, and marine environments. Its corrosion resistance allows for use in both indoor and outdoor settings exposed to harsh elements.Q: What customization options are available for Monel 400 wire mesh?

A: We offer a range of customization options, including dimension adjustments, wire diameter, aperture size, and mesh shape. These can be tailored to meet your exact application requirements, ensuring optimal fit and utility for any industrial project.Q: How is the wire mesh manufactured and treated for application-specific demands?

A: Monel 400 wire mesh is manufactured with a plain weave technique, and surface treatments are available as required by the application. This ensures additional durability or resistance when exposed to particularly harsh substances or operational conditions.Q: What are the advantages of sourcing Monel 400 wire mesh from an Indian exporter or supplier?

A: Partnering with an Indian exporter or supplier offers reliable access to high-quality, customizable wire mesh at competitive prices. With extensive manufacturing expertise, suppliers from India ensure timely delivery and tailored solutions for your industrial needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plain Weave Wire Mesh Category

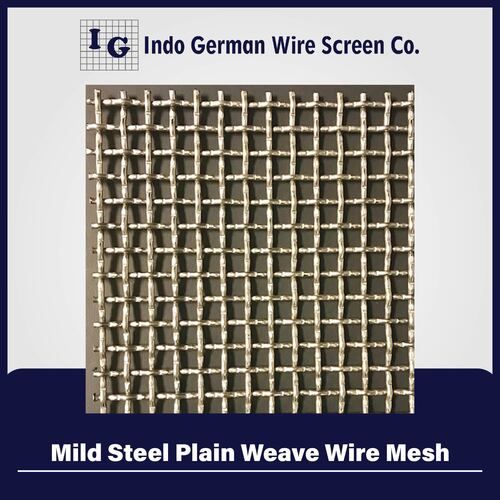

Mild Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Plain Weave

Color : Gray

Mesh Style : Plain Mesh

Wire Gauge : 10 to 30 SWG

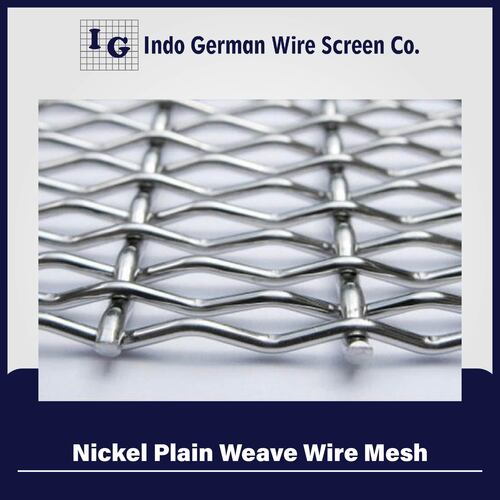

Nickel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Plain Weave

Color : Gray

Mesh Style : Plain Mesh

Wire Gauge : Customizable, commonly ranges from 10 to 80 SWG

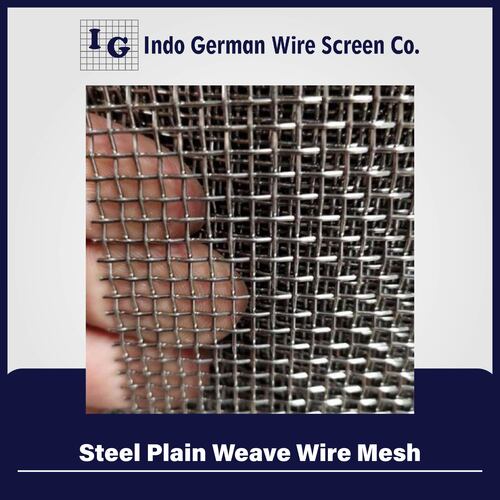

Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Woven Mesh

Color : Gray

Mesh Style : Plain Mesh

Wire Gauge : 18 SWG

Nichrome A Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Woven Mesh

Color : Gray

Mesh Style : Plain Mesh

Wire Gauge : 40 SWG to 10 SWG

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry