Titanium Woven Wire Mesh

Price 50 INR/ Unit

Titanium Woven Wire Mesh Specification

- Aperture

- 0.05 mm to 10 mm, customizable

- Length

- 30 meters (standard roll), customizable

- Surface Treatment

- Coated

- Wire Gauge

- As per requirement (customizable, range typically 2 to 50 mesh)

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave / Twill Weave (upon request)

- Mesh Style

- Woven Mesh

- Material

- Titanium

- Alloy

- Titanium Grade 1, 2, 5 or as per customer requirement

- Application

- Filtration, chemical processing, marine, aerospace, medical, battery, paper and pulp, seawater desalination

- Dimensions

- Width 1 m (standard), length customizable

- Wire Diameter

- 0.02 mm to 2 mm

- Weight

- Variable, depends on dimensions and mesh count

- Color

- Silver

Titanium Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Titanium Woven Wire Mesh

Titanium is known for its high durability, light weight, high strength, and corrosion-resistant properties. Titanium metal is resistant to saltwater, metallic salts, hydroxides, chromic acids, chlorides, nitric acids, organic acids, and dilute alkalis. Titanium is available in black colour, with diverse weaving patterns of plain and twill weave.The mesh itself will remain strong and stable with a high percentage of open area. Different patterns such as plain weave, twilled weave, and plain dutch weave are made on these types of weaving looms.Titanium Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Titanium Woven Wire mesh is ideal for both industrial & architectural applications.Unmatched Corrosion Resistance

Titanium woven wire mesh stands out due to its exceptional ability to withstand corrosive environments, including acidic, alkaline, and seawater conditions. This makes it a preferred choice for chemical processing, marine, and seawater desalination industries, ensuring longevity and reduced maintenance.

Superior Mechanical Strength

With a tensile strength of up to 240 MPa (Grade 2), titanium mesh offers impressive durability. Its robust structure allows it to maintain integrity under heavy mechanical stress, making it suitable for filtration, structural, and aerospace applications where resilience is paramount.

Versatile Customization Options

Available with plain or selvage edges, varied mesh styles (plain or twill weave), and customizable dimensions, titanium woven mesh meets diverse application needs. Clients can select specific wire diameters, mesh counts, and packing methods tailored to their projects requirements.

FAQs of Titanium Woven Wire Mesh:

Q: How is titanium woven wire mesh manufactured and finished?

A: Titanium woven wire mesh is produced by weaving titanium wires into various patterns such as plain or twill weave. The mesh can be finished with either plain or selvage edges and may receive surface coatings to enhance performance. Packing is typically done as rolls, with moisture-proof materials for protection during storage and transport.Q: What makes titanium woven wire mesh ideal for corrosive environments?

A: Titanium naturally forms a passive oxide layer, providing it with outstanding resistance against acids, alkalis, and salt water. This corrosion resistance means the mesh remains structurally sound even in aggressive chemical or marine settings, making it especially beneficial for filtration and process industries.Q: When should I choose titanium mesh over other metal meshes?

A: Select titanium mesh when your application requires a combination of strong mechanical properties, high corrosion resistance, and thermal stability. It is often chosen for demanding industries like chemical, medical, marine, and aerospace, where conventional materials might fail due to corrosion or strength limits.Q: Where is titanium woven wire mesh commonly used?

A: This mesh is widely utilized in sectors such as filtration systems, chemical processing plants, marine engineering, aerospace, battery technology, medical devices, paper manufacturing, and seawater desalination facilities, thanks to its blend of mechanical toughness and corrosion resistance.Q: What customization options are available for titanium woven wire mesh?

A: Clients can customize wire gauge (typically 2 to 50 mesh), aperture size (0.05 mm10 mm), wire diameter (0.02 mm2 mm), length, width, mesh type (plain/twill weave), surface treatment, and alloy grade (Grade 1, 2, 5). Packing methods and edge finishes are also tailored to individual needs.Q: How should titanium woven wire mesh be maintained for best performance?

A: Titanium mesh requires minimal upkeep. Periodic inspection and simple cleaning are usually adequate, as it resists corrosion and buildup. Proper storage in moisture-proof packaging further extends its service life in demanding environments.Q: What are the primary benefits of using titanium woven wire mesh?

A: The main advantages include robust mechanical strength, exceptional resistance to corrosion, high temperature tolerance, and adaptability to various industrial applications. Its long lifespan and reliability make it a cost-effective solution for critical operational settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

Inconel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Plain Weave / Twill Weave

Color : Silver

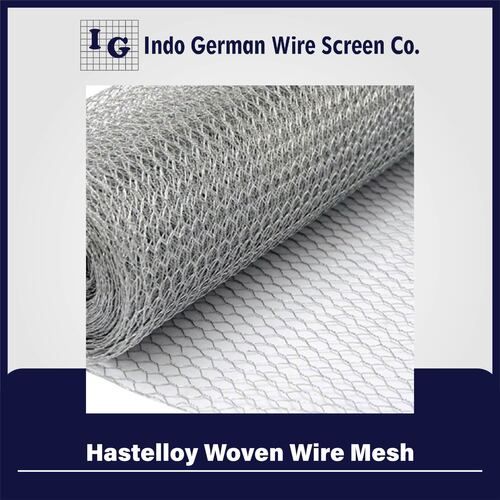

Hastelloy Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Fine Mesh / Crimped Mesh (optional)

Color : Silver

Nickel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Woven Wire Mesh

Application : Other, Filtration, Battery Electrode, Chemical Processing, Laboratory, Aerospace, Electronics

Mesh Type : Other , Woven

Color : Silver Grey

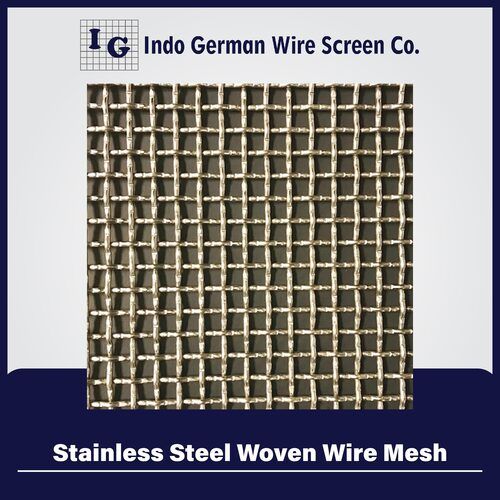

Stainless Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Woven Wire Mesh

Application : Other, Filtration, Sieving, Security, Industrial, Architectural

Mesh Type : Other , Woven Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry