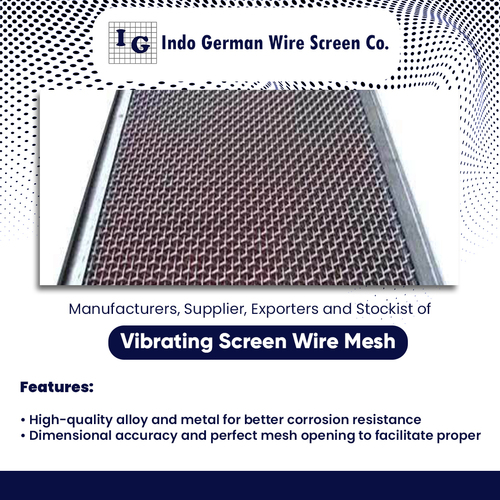

Vibrating Screen for Separation

Price 50 INR/ Unit

Vibrating Screen for Separation Specification

- Surface Treatment

- Coated

- Aperture

- 2 mm 100 mm

- Hole Shape

- Rectangular / Square

- Length

- Customizable

- Wire Gauge

- As per requirement

- Product Type

- Wire Mesh

- Mesh Type

- Vibrating Screen Mesh

- Mesh Style

- Plain Mesh

- Material

- Metal Alloys

- Alloy

- Stainless Steel / High Carbon Steel

- Application

- Other

- Dimensions

- Up to 6 ft x 20 ft

- Wire Diameter

- 1 mm 12 mm

- Weight

- As per size & material

- Color

- Silver

Vibrating Screen for Separation Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen for Separation

Vibrating Screensprovide a custom engineered solution for all heavy-duty applications for minerals, ores, aggregates, and more.Vibrating Screens aremade for durability to give you longer wear life and maximum strength steel to bear heavy loading. Our Vibrating Screens are available in a range of sizes from 8 x 4 (2.4 m x 1.2 m) to 8 x 24 (2.4 m x 7.3 m).

Vibrating Screen Wire Mesh for Separationis available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofVibrating Screen Wire Mesh for Separationat unmatched quality and market leading prices.

Precision Engineering for Reliable Separation

Our vibrating screens are crafted with robust frame materials and high tensile wire alloys, allowing for effective separation, screening, and sieving in industrial settings. The clamped, bolted, or welded edge designs provide stability, adaptability, and resilience under demanding operational conditions, making them suitable for diverse processing applications.

Customizable Mesh and Dimensions for Every Need

We offer a variety of mesh styles, wire diameters, hole shapes, and dimensions, all customizable as per your exact requirements. Aperture sizes range from 2 mm to 100 mm and lengths up to 20 ft, ensuring there is an optimal solution for each application in terms of throughput, precision, and efficiency.

Durability and Resistance for Tough Environments

Our vibrating screens are fabricated using materials that are highly resistant to corrosion and temperatures reaching 300C, with a protective coating for enhanced longevity. This durability translates into reduced downtime, consistent performance, and a lower total cost of ownership for your screening operations.

FAQs of Vibrating Screen for Separation:

Q: How does the vibrating screen facilitate material separation?

A: The vibrating screen operates by agitating materials using a vibratory motor, causing particles to move across the mesh surface. Smaller particles pass through the engineered apertures, while larger particles remain on top, ensuring effective separation, sieving, and screening across various industrial processes.Q: What materials are used in the construction of your vibrating screens?

A: Our vibrating screens are constructed using premium mild steel, stainless steel, and high carbon steel alloys. These materials offer high tensile strength, durability, heat resistance up to 300C, and excellent corrosion resistance, making the screens ideal for demanding operational environments.Q: When should I opt for perforated or woven mesh processing?

A: Perforated mesh is recommended for applications requiring large aperture sizes or specific hole shapes for targeted separation. Woven mesh is better suited for fine sieving tasks where uniformity and precision are essential. The choice depends on your screening requirements and the material characteristics.Q: Where can these vibrating screens be installed?

A: Our vibrating screens are versatile and can be installed in various industries such as mining, food processing, chemicals, pharmaceuticals, and construction. They are suitable for inline process integration or standalone use, providing efficient separation and screening wherever required.Q: What are the benefits of choosing a customizable vibrating screen?

A: Customizable vibrating screens allow you to select mesh type, wire gauge, frame material, dimensions, and aperture size as per your specific process needs. This flexibility ensures optimal performance, maximized throughput, and enhanced operational efficiency, regardless of application complexity.Q: How is the durability of the screen ensured over prolonged use?

A: Durability is achieved by utilizing high tensile, coated metal alloys and secure edge preparation methods like clamping, bolting, or welding. The corrosion-resistant materials and surface treatments protect against wear, while the robust construction allows for reliable operation in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Silver

Material : Metal Alloys

Vibrating Screen Wire Mesh for Coal Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Screening and grading coal in mining industry

Surface Treatment : Coated

Color : Silver

Material : Metal Alloys

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Silver

Material : Metal Alloys

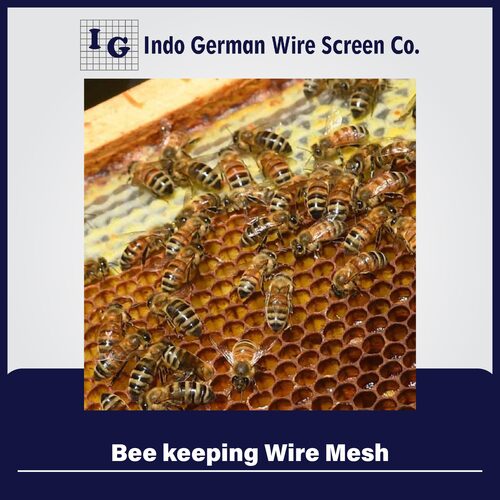

Bee keeping Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Silver

Material : Metal Alloys

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry