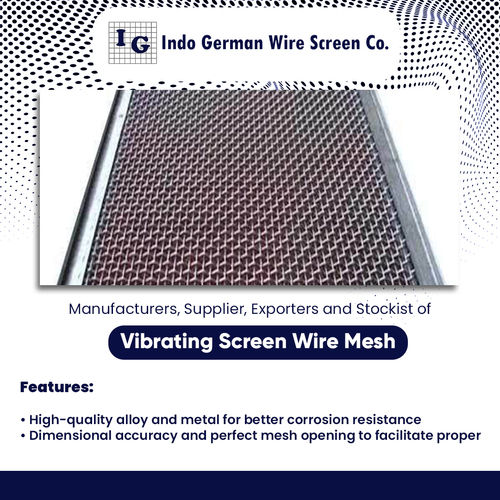

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR/ Unit

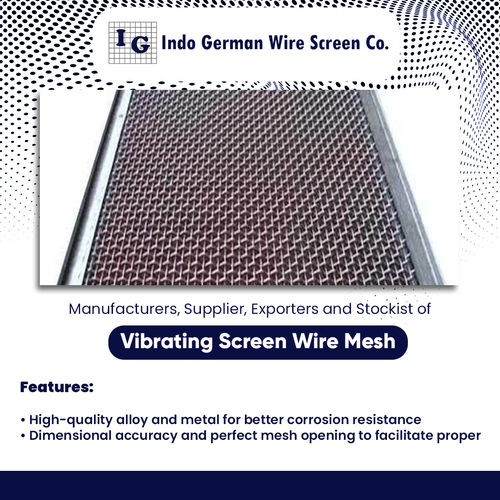

Vibrating Screen Wire Mesh for Steel Industry Specification

- Aperture

- 0.5 mm to 100 mm

- Wire Gauge

- 10 Gauge to 25 Gauge

- Hole Shape

- Square / Rectangular

- Length

- As per requirement

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Woven/Crimped

- Mesh Style

- Other

- Material

- Metal Alloys

- Alloy

- High-carbon steel/stainless steel/alloy steel

- Application

- Other

- Dimensions

- Custom size available

- Wire Diameter

- 0.6 mm to 6 mm

- Weight

- Variable as per size and gauge

- Color

- Silver

- Usage

- Ideal for vibrating screens in steel industry, quarrying, and mining

- Packaging Type

- Rolls or cut panels, as specified

- Corrosion Resistance

- Yes, due to coated treatment

- Finish

- Smooth, rust-resistant finish

- Tensile Strength

- High tensile strength for robust operation

- Opening Size

- As per customer's requirement

- Load Bearing Capacity

- Designed for heavy-duty applications

- Edge Preparation

- Flat, folded, hooked or customized type

Vibrating Screen Wire Mesh for Steel Industry Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen Wire Mesh for Steel Industry

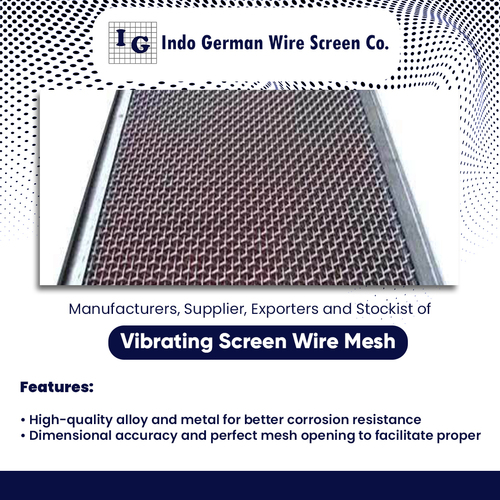

Vibrating Screensprovide a custom engineered solution for all heavy-duty applications for minerals, ores, aggregates, and more.Vibrating Screens aremade for durability to give you lengthier wear life and maximum strength steel to bear heavy loading. Our Vibrating Screens are available in a range of sizes from 8x 4 (2.4 m x 1.2 m) to 8x 24(2.4 m x 7.3 m).Vibrating Screen Wire Mesh for Steel Industryis available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofVibrating Screen Wire Mesh for Steel Industryat unmatched quality and market leading prices.

Versatile Performance for Demanding Environments

This vibrating screen wire mesh is engineered for rigorous applications in the steel industry, mining, and quarrying. High tensile strength and heavy-duty construction allow for reliable operation under challenging conditions. Its corrosion-resistant coating ensures longevity, even in environments with high moisture or aggressive materials.

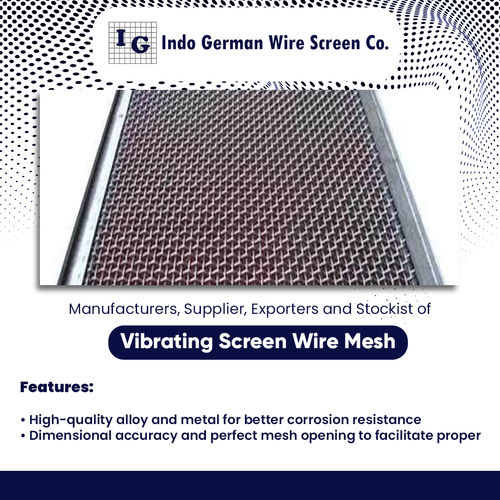

Customizable to Fit Your Requirements

With a broad range of apertures (0.5 mm to 100 mm), wire diameters (0.6 mm to 6 mm), mesh types (woven/crimped), and customizable dimensions, this wire mesh caters to specific operational needs. Edge preparation and finish options further tailor the product to suit diverse installation preferences and performance requirements.

FAQs of Vibrating Screen Wire Mesh for Steel Industry:

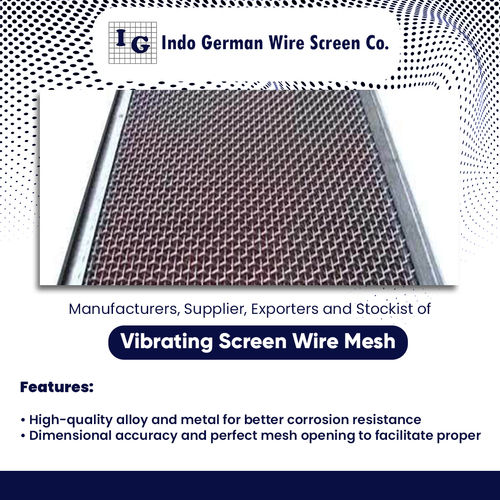

Q: How is the vibrating screen wire mesh customized for different industrial applications?

A: The wire mesh can be customized in terms of opening size, wire diameter, dimensions, and edge preparation. Options include flat, folded, hooked, or custom edges, with multiple material choices such as high-carbon steel, stainless steel, or alloy steel, ensuring optimal performance for varying operational demands.Q: What process is used to ensure corrosion resistance in the mesh?

A: The mesh undergoes a specialized surface treatment, receiving a rust-resistant coating that protects against corrosion and extends service life, making it suitable for heavy-duty use in harsh environments like steel manufacturing and mining.Q: When should I choose woven or crimped mesh styles?

A: Woven and crimped mesh styles serve different needs. Woven mesh offers a smoother surface, suitable for applications requiring precise particle separation, while crimped mesh delivers additional rigidity and is ideal for heavy-load situations.Q: Where can this wire mesh be effectively used?

A: This wire mesh is ideal for vibrating screens in the steel industry, quarrying, and mining sectors due to its durability, load-bearing capacity, and adaptability to specific requirements, ensuring efficient material separation and screening.Q: What are the main benefits of using high-tensile wire mesh in steel industry applications?

A: High-tensile wire mesh provides enhanced strength, long service life, resistance to wear and corrosion, and the ability to handle substantial loads, reducing maintenance downtime and improving process efficiency.Q: How is the vibrating screen wire mesh typically packaged and delivered?

A: Depending on customer requirements, the mesh is supplied in rolls or as cut panels. Custom packaging ensures the products condition is maintained during transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Vibrating Screen Mesh

Application : Other

Product Type : Wire Mesh

Material : Metal Alloys

Vibrating Screen Wire Mesh for Cement Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Vibrating Screen Mesh

Application : Other

Product Type : Wire Mesh

Material : Metal Alloys

Vibrating Screen Wire Mesh for Sieving

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Welded or Woven

Application : Other

Product Type : Wire Mesh

Material : Metal Alloys

Vibrating Screen Wire Mesh for Coal Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Crimped, Welded, or Plain Weave

Application : Other, Screening and grading coal in mining industry

Product Type : Wire Mesh

Material : Metal Alloys

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry