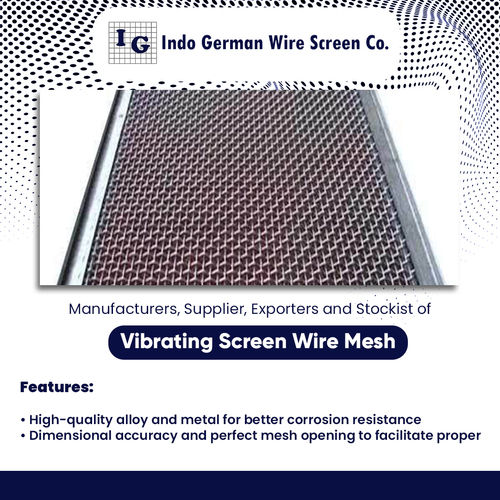

Vibrating Screen Wire Mesh for Minerals

Price 50 INR/ Unit

Vibrating Screen Wire Mesh for Minerals Specification

- Wire Gauge

- 12 to 16 SWG

- Aperture

- 0.5 mm to 80 mm

- Surface Treatment

- Coated

- Hole Shape

- Square / Rectangular

- Length

- Up to 30 meters

- Product Type

- Wire Mesh

- Mesh Type

- Vibrating Screen Mesh

- Mesh Style

- Other

- Material

- Metal Alloys

- Alloy

- Stainless Steel / High Carbon Steel

- Application

- Other

- Dimensions

- Custom as per requirement

- Wire Diameter

- 0.8 mm to 5 mm

- Weight

- Variable as per size

- Color

- Silver

- Tensile Strength

- Enhanced for heavy loads

- Usage

- Mineral Processing, Mining, Quarrying

- Installation

- Easy to Install & Replace

- End Finish

- Double Crimped, Flat Panels

- Corrosion Resistance

- Excellent

- Open Area %

- As per mesh size

- Temperature Resistance

- High

- Packing Type

- Rolls or Cut Panels

- Type

- Heavy-Duty Vibrating Screen

- Service Life

- Long-lasting

- Edge Type

- Hooked / Welded / Plain Edge

Vibrating Screen Wire Mesh for Minerals Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen Wire Mesh for Minerals

Vibrating Screens is also known as Industrial vibrating screen, wire cloth, crusher screen is extensively used in minerals processes. Vibrating screens products are widely applicable in different industries for their various applications and come in different sizes and dimensions as well as based on customized needs of our customers. The Vibrating Screens are manufactured using high-grade materials in accordance with industry standards.

Vibrating Screens are made for durability to give you lengthier wear life and maximum strength steel to bear heavy loading. Our Vibrating Screens are available in a range of sizes from 8 x 4(2.4 m x 1.2 m) to 8x 24(2.4 m x 7.3 m).

Engineered for Rugged Environments

Our vibrating screen wire mesh stands up to the toughest operating conditions in mineral processing and mining. With high temperature and corrosion resistance, along with enhanced tensile strength, these meshes are ideal for heavy loads and prolonged use, minimizing downtime and maintenance. Customization in size, gauge, and configuration offers precise compatibility with your application needs.

Superior Quality & Versatile Applications

Manufactured using stainless steel and high carbon steel, our wire mesh panels adhere to global quality standards. They cater to a multitude of usesmineral processing, quarrying, and moredelivering consistent screening performance. The mesh is available in various end finishes, edge types, and can be supplied as rolls or cut panels, tailored for hassle-free installations.

FAQs of Vibrating Screen Wire Mesh for Minerals:

Q: How do I determine the optimal mesh aperture size for my mineral processing application?

A: Selecting the best mesh aperture size depends on the material size you need to separate or screen. Our vibrating screen wire mesh offers apertures from 0.5 mm to 80 mm, allowing for efficient separation of various mineral sizes. For guidance, consult our technical team to match your mineral requirements with an appropriate mesh size.Q: What makes this vibrating screen wire mesh suitable for heavy-duty mineral processing?

A: Designed with enhanced tensile strength, high-quality coated metal alloys, and robust construction, our mesh withstands heavy loads and extended usage. The double crimped, flat panels maintain structural integrity, while excellent corrosion and temperature resistance ensure reliability even in demanding mineral processing environments.Q: When should I replace the vibrating screen wire mesh?

A: Replacement intervals depend on material type, volume throughput, and operating conditions. However, the long service life and sturdy design of our wire mesh mean less frequent replacements compared to standard options. Regular inspections for wear or damage will help determine the optimal replacement schedule and maintain peak performance.Q: Where can these vibrating screen wire meshes be installed?

A: These meshes are compatible with most standard screening equipment used in mineral processing plants, mining operations, and quarries. Custom dimensions and multiple edge types ensure seamless fitting for various screen frames and machinery as required by your specific setup.Q: How is the vibrating screen mesh installed and replaced?

A: Installation is simple: The mesh panelswith your choice of hooked, welded, or plain edgesare designed for swift mounting and removal. Detailed instructions and support are provided to help your team efficiently install or replace the panels, minimizing downtime during maintenance.Q: What process guarantees the quality and durability of your vibrating screen wire mesh?

A: Our manufacturing process utilizes high-grade stainless steel or high carbon steel alloys, precision wire drawing, advanced double crimping, and specialized protective coatings. This ensures each mesh meets stringent standards for tensile strength, corrosion resistance, and longevity.Q: What are the main benefits of using your vibrating screen wire mesh in mineral processing?

A: You gain enhanced screening efficiency, reduced maintenance, long service life, and dependable performance under extreme conditions. The customizable options in mesh size, edge type, and panel dimensions make it ideal for a broad range of mineral processing needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

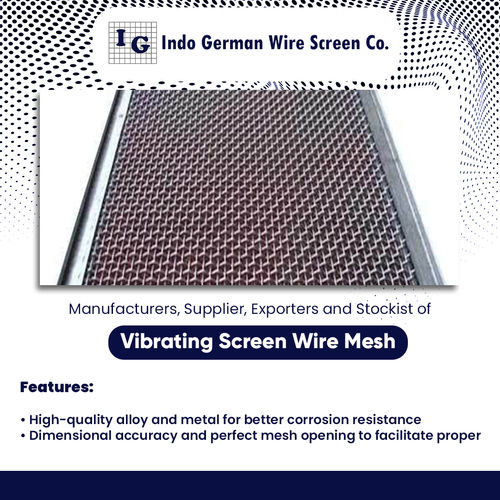

Vibrating Screen for Separation

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

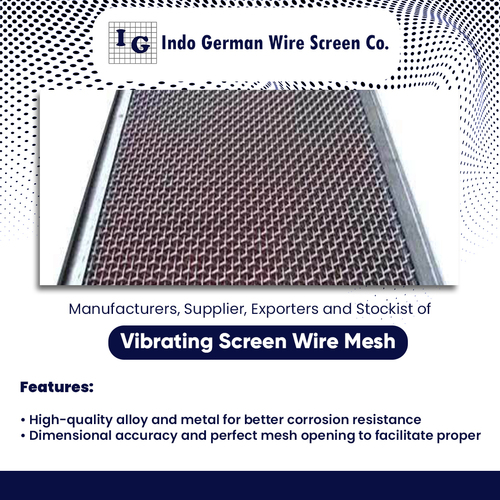

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Bee keeping Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Vibrating Screen for Refining

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Other, Vibrating Screen

Color : Silver

Surface Treatment : Polished

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry